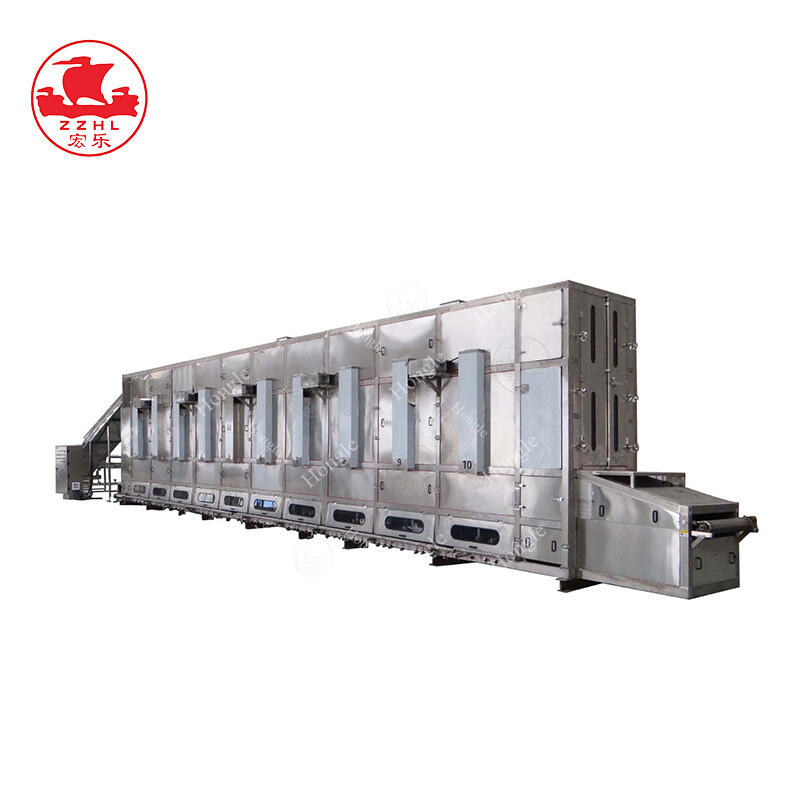

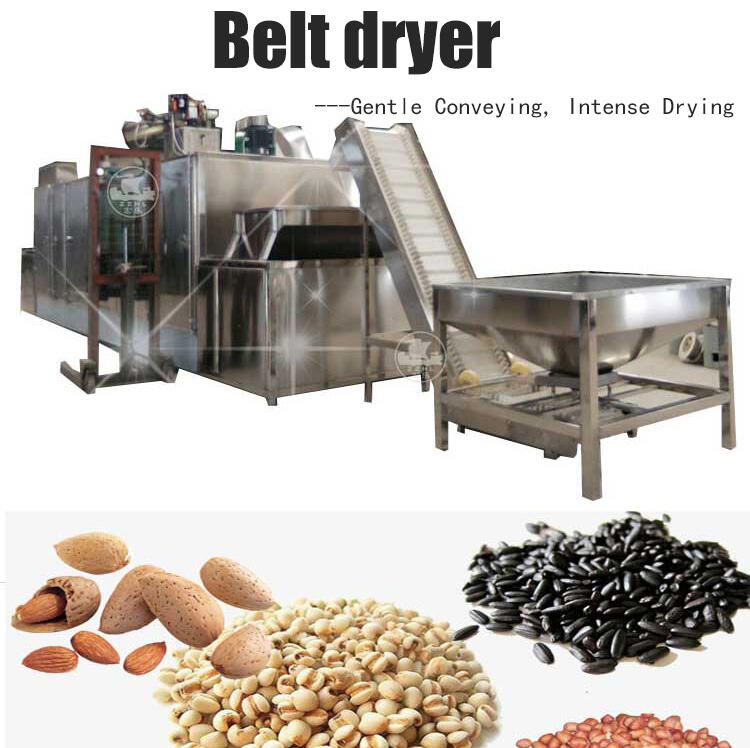

belt drying machine Fruit drying Vegetable dehydration Agricultural product dehydration special equipment

Temperature adjustable from 40°C to 180°C fully automatic conveyor belt stainless - steel chamber for heat locking and energy saving An efficient equipment for dried fruit processing and commercial food drying

- Overview

- Product Advantages

- Application Scenarios

- Technical Parameters

- Detailed Information

- Recommended Products

belt drying machine Fruit drying Vegetable dehydration Agricultural product dehydration special equipment

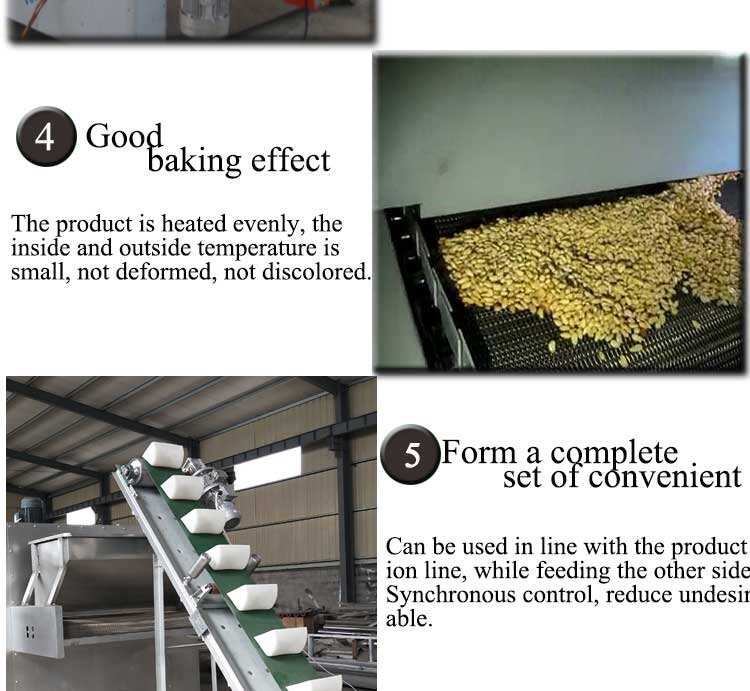

The belt-type hot air dryer is an industrial-grade continuous drying equipment that integrates the conveying belt system with forced hot air circulation. As a specialized equipment for processing dried fruits, it uses electricity, gas or steam for heating to create stable hot air. When this hot air passes through the stainless steel conveyor belt, it evenly penetrates the interior of the materials. The temperature (40 - 180℃) and conveyor belt speed of this equipment can be adjusted, allowing for precise control of moisture removal. It is highly suitable for large-scale dehydration processing of fruits, vegetables and agricultural products. Its automated design ensures the continuous operation of the processing process, while the insulation chamber can minimize heat loss to the greatest extent, making it an ideal equipment for commercial food processing and bulk material drying.

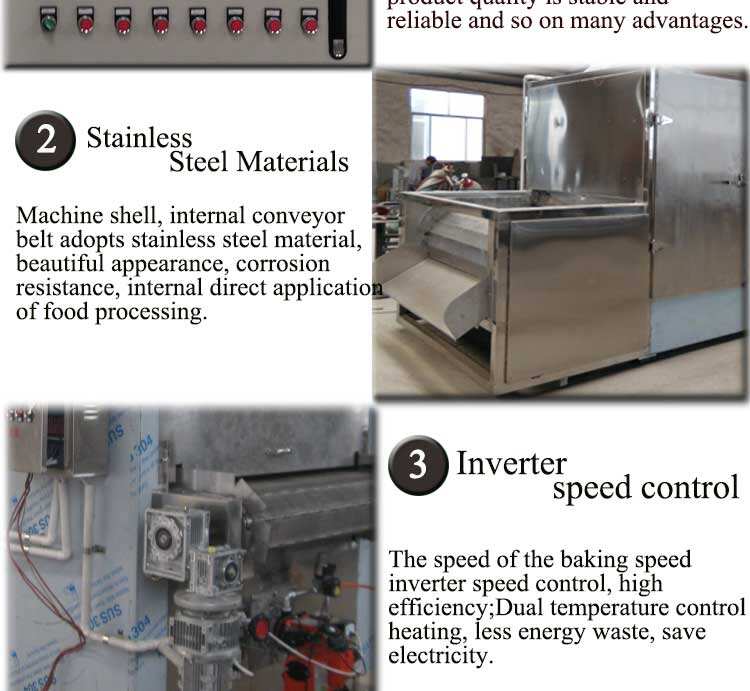

Product Advantages

Efficient Hot Air Circulation: 360° uniform hot air distribution ensures consistent drying, preserving the color and texture of fruits (a key benefit for Dry Fruit Machine applications).

Continuous High Output: Conveyor belt system enables 24/7 operation, handling 800-10,000kg/day—perfect for large-scale production lines.

Energy-Saving Design: Insulated chamber and heat recovery system reduce energy consumption by 25% compared to traditional belt dryers.

Flexible Parameter Control: Adjustable temperature, air flow, and belt speed adapt to heat-sensitive materials (e.g., berries) and sturdy crops (e.g., potatoes).

Durable & Hygienic: Food-grade stainless steel belt and chamber resist corrosion; easy-to-clean structure meets FDA and CE standards.

Labor Reduction: Automated feeding, drying, and discharge minimize manual work, improving efficiency for commercial drying operations.

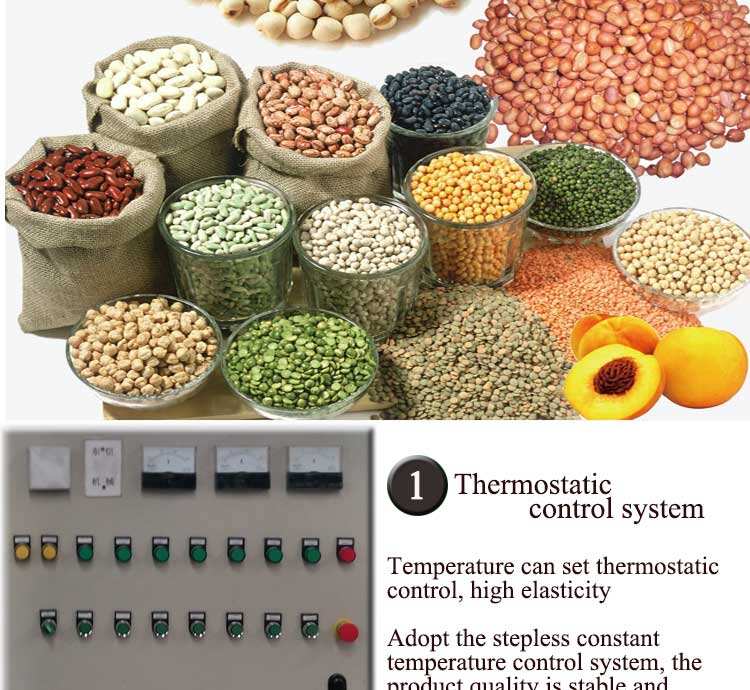

Application Scenarios

Dry Fruit Production: Dries apples, bananas, mangoes, and pineapples into dried fruits—retaining natural sweetness and nutrients (core use as a Dry Fruit Machine).

Vegetable Processing: Dehydrates carrots, onions, and bell peppers for use in instant soups, snacks, or seasoning blends.

Agricultural Processing: Dries grains (corn, oats), herbs (mint, basil), and cash crops (tobacco, tea) for storage and market distribution.

Food Industry: Processes meat slices, seafood, and nuts—removing moisture to extend shelf life without compromising taste.

Industrial Materials: Dries non-food items like paper, textiles, and small plastic parts with controlled hot air to avoid deformation.

Technical Parameters

| Item | Value |

| Core Components | MOTOR |

| Place Of Origin | China |

| Brand Name | Hongle |

| Warranty | 1 Year |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Applicable Materials | Fruit、Vegetable、Meat |

| Voltage | 380V |

| Total Power | 30kw |

| Dimension(L*W*H) | 6415*3185*4130 (mm) |

| Transmission | Chain Drive |

| Mesh belt Specification | W=1800, polyurethane food grade mesh belt, mesh number 2x2mm, wire diameter 0.9mm |

| Mesh Belt layer quantity | 5 layer |

| Drying Chamber | 5 hot air circulating units; |

| Transmission Motor | Power: 7.5kw |

| Transmission Speed Range | 0.6~1.4m/min |

| Circulation Fan | 1) Power: 2.2kw axial Fan |

| Dehumidification fan | Power: 2.25kw |

| Heating Source | 1) Steam, steam pressure 0.4~0.6MPa |

| Steam Consumption | 300kg/h or so |

| Electricity Control System | Siemens PLC;Siemens touch screen; automatic temperature |

| Control panel | Independent control panel centralized control |

Detailed Information