Fruit Vegetable Agricultural Product Dehydration Air Source Heat Pump Drying Machine

Adjustable temperature energy-saving Food-grade stainless steel Industrial and commercial drying machine

- Overview

- Product Advantages

- Application Scenarios

- Technical Parameters

- Detailed Information

- Recommended Products

Fruit Vegetable Agricultural Product Dehydration Air Source Heat Pump Drying Machine

The air-source heat pump dryer is a highly energy-efficient drying system that operates by extracting thermal energy from the ambient environment using air-source heat pump technology. This extracted heat is then converted into high-temperature air, which facilitates the evaporation and removal of moisture from the target materials. Owing to its closed-loop operational design, the energy consumption of this system is approximately 50% lower than that of conventional electric dryers, making it well-suited for dehydration processes in industrial and commercial applications.

Equipped with adjustable temperature control (ranging from 20 to 80°C) and humidity regulation capabilities, the dryer ensures a consistent and controlled drying environment. This enables a gentle and uniform drying process that effectively preserves the original color, flavor, and nutritional properties of the processed materials. Constructed entirely from stainless steel, the unit complies with food-grade safety standards. It has been extensively adopted across multiple sectors, including food processing, agricultural production, and industrial manufacturing.

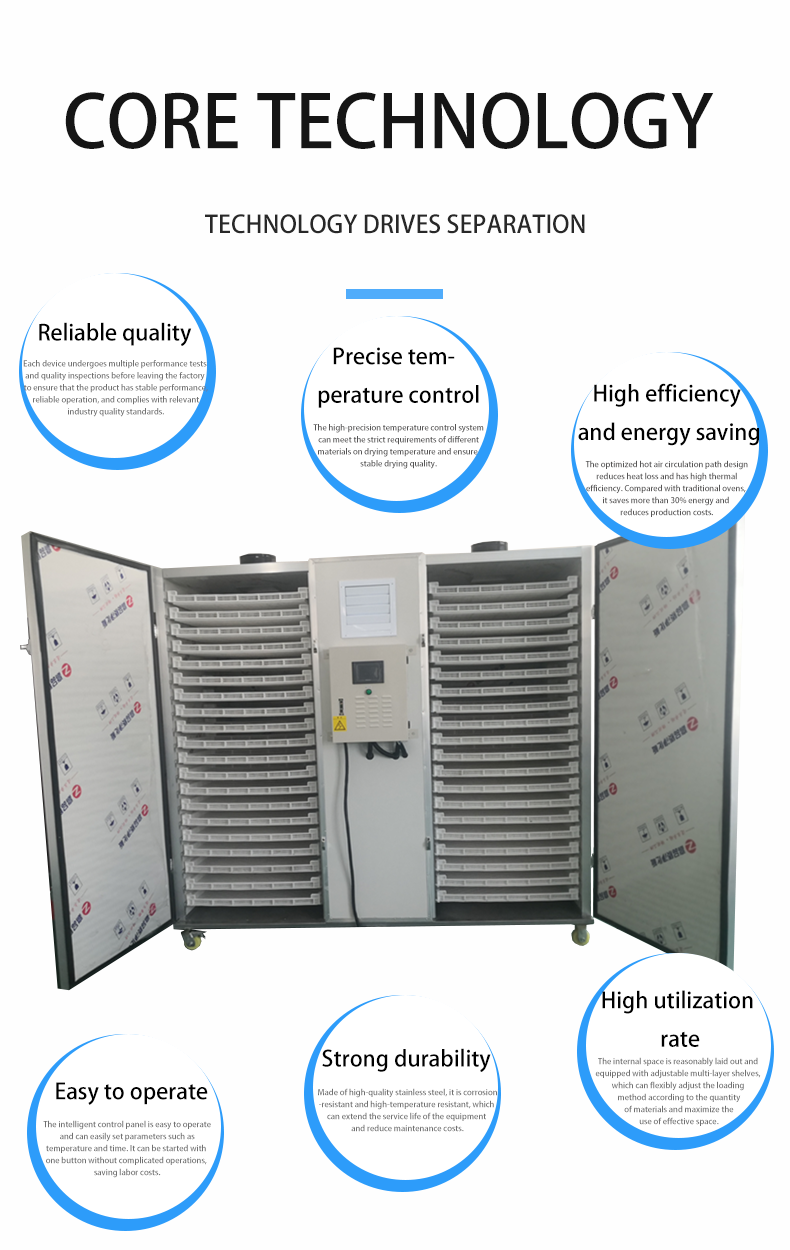

Product Advantages

Energy Efficiency: Air source heat pump technology reduces energy costs by 50-70% compared to electric or gas dryers.

Gentle Drying: Low-temperature (20-80℃) operation preserves nutrients, color, and flavor of heat-sensitive materials (e.g., fruits, herbs).

All-Weather Operation: Works efficiently in temperatures -10℃ to 40℃, suitable for various climates.

Uniform Dehydration: 360° air circulation ensures consistent moisture removal, avoiding over-drying or under-drying.

Eco-Friendly: No emissions, low noise, and compliant with environmental standards (CE, RoHS).

Durable & Safe: Stainless steel chamber resists corrosion; built-in overheat protection and auto-shutdown function.

Intelligent Control: Digital panel with precise temp/humidity settings, supporting automatic drying cycles.

Application Scenarios

Food Processing: Drying fruits (mango, strawberry), vegetables (bell pepper, onion), meat (beef jerky, pork), and seafood (shrimp, fish).

Agriculture: Dehydrating grains (rice, corn), medicinal herbs (ginseng, chrysanthemum), and cash crops (tobacco, tea).

Herbal & Pharmaceutical: Drying medicinal plants and herbal extracts without losing active ingredients.

Textile & Leather: Drying fabrics, leather products, and fibers with controlled humidity to prevent shrinkage.

Industrial Materials: Dehydrating plastics, ceramics, and electronic components with low-temperature settings to avoid damage.

Technical Parameters

| Item | Value |

| Core Components | MOTOR |

| Place Of Origin | China |

| Brand Name | Hongle |

| Warranty | 1 Year |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Applicable Materials | Fruit、Vegetable、Meat |

| Voltage | 380V |

| Power | 50kw |

| Dimension(L*W*H) | 6100*3200*2710mm |

| Weight | 1000kg |

| Output | 10-1000kg/h |

| Size of the feed car (length× width× height) | 1400*900*1930mm |

| Structural form | Monolithic box type |

| Material dehydration method | Overall dehydration |

| Number of trolley | 9 |

| Number of trays | 153pcs |

| Heating system | Air energy heat pump unit heat recovery type 15P all-in-one machine |

| Drying temperature | Room temperature - 75°C can be set in multiple stages |

| Temperature and humidity control equipment | Automatic temperature control |

| Insulated doors | Insulation door: 50mm double-sided color steel polyurethane foam board, foam density: 40kg/m³, |

| walls | Thermal insulation room: 75mm thick double-sided color steel polyurethane foam board, foaming density: 40kg/m³, |

Detailed Information