क्रीम भरने की मशीन पेस्ट स्टेनलेस स्टील खाद्य पदार्थ और पेय तरल मोटी पेस्ट भरने की मशीन

- सारांश

- अनुशंसित उत्पाद

उपयोग:

भरने की मशीन रोजमर्रा की केमिकल उद्योग, खाद्य उद्योग, प्रिंटिंग इंक और पेंट उद्योग के लिए पेस्ट भरने के लिए।

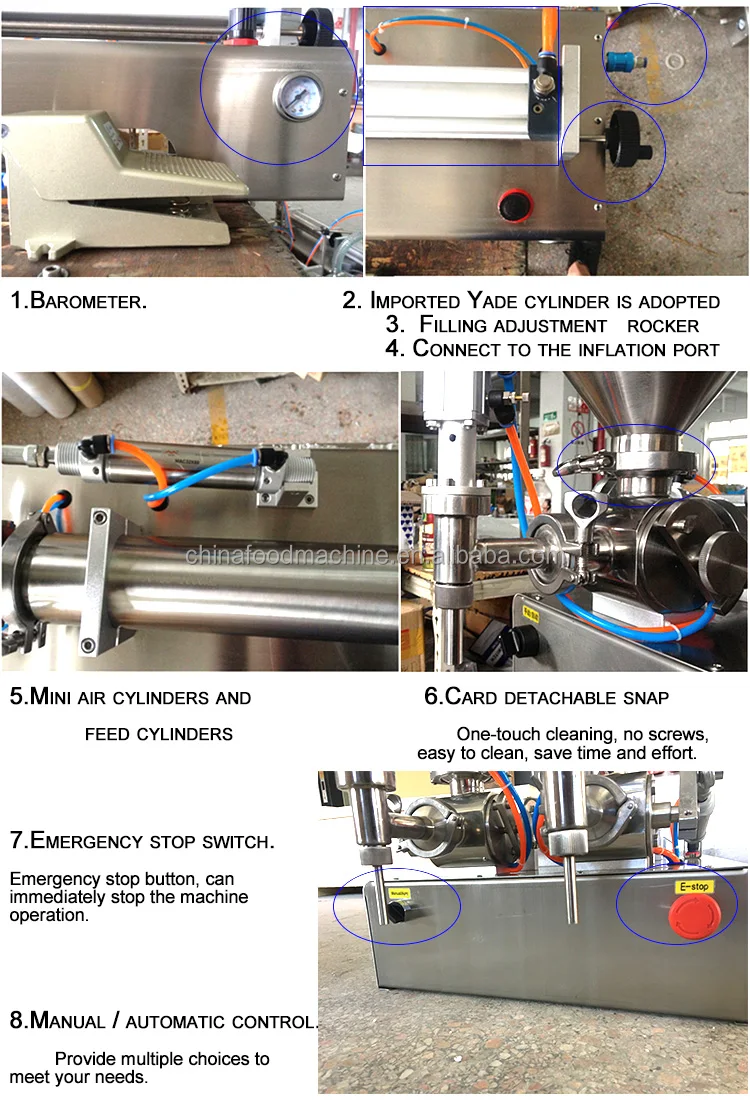

विशेषता:

1. मध्यम चिपचिपी और उच्च चिपचिपी उत्पाद के लिए भरने की मशीन कैन की आवश्यकता है जिसे विकसित करना है

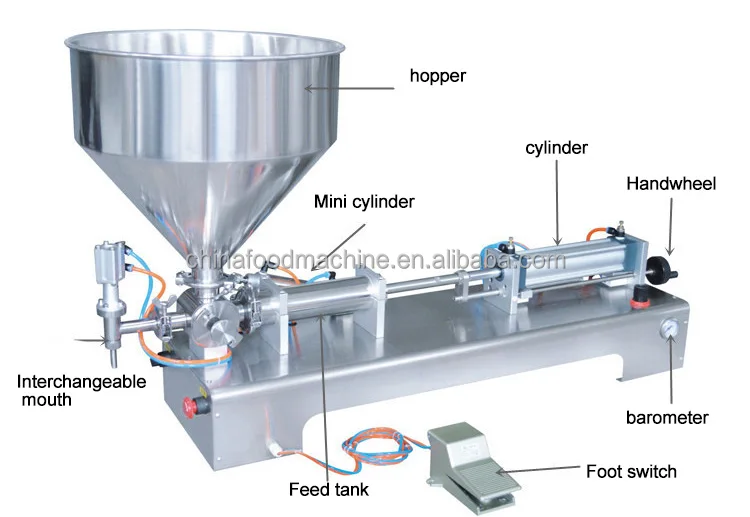

2. पूरी मशीन में एक स्टोरेज हॉपर होता है, दो महत्वपूर्ण भाग बिजली का अलमारी है, संरचना सरल है, संचालन सुविधाजनक है।

3. सिलेंडर पिस्टन और सिलेंडर ब्लॉक PTFE और स्टेनलेस स्टील पदार्थों से बने होते हैं, GMP की मांगों के अनुरूप।

4. भरने की मात्रा और भरने की गति को समायोजित किया जा सकता है, और भरने की सटीकता उच्च है।

5. ड्रिप-टाइट कैनिंग का उपयोग करें, ताकि तार भरने वाले उपकरण से रोका जा सके।

6. मशीन को विस्फोट-सुरक्षित भरने वाले प्रणाली की मांगों के अनुसार संशोधित किया जा सकता है।

सिद्धांत और विशेषता:

यंत्र को डिजिटल संख्या वाले आयतन समायोजन मीटर, 4 मीटर की फ्रीक्वेंसी कनवर्शन टाइमिंग कनवेयर बेल्ट, स्वचालित सेंसर वाली कैपिंग मशीन और वैक्यूम एंटी-ड्रॉपिंग डिवाइस से सुसज्जित किया गया है।

यंत्र का सुंदर आकार, उच्च भरण सटीकता, सुविधाजनक समायोजन और आसान संचालन जैसी विशेषताएँ हैं।

डिजिटल संख्या द्वारा भरण आयतन को प्रदर्शित करें।

माइक्रोकंप्यूटर के पीएलसी प्रोग्राम द्वारा नियंत्रित।

डबल स्पीड भरण-नियंत्रण प्रौद्योगिकी।

6. कम्प्यूटर द्वारा योग्यता परिमाण और सीधी लाइन द्वारा भरना।

7. एंटी-ड्रॉपिंग वैल्व युक्त भरण खंड।

8. स्टेनलेस स्टील से बना हुआ।

मॉडल |

HL-MGF100-5000 |

वोल्टेज |

AC220/110V 50-60Hz |

शक्ति |

20W |

आवश्यक हवा संपीड़क |

0.4-0.6Mpa \/ ≥1.5kw 65L |

भरने की गति |

4-18 bpm भरने के आयतन पर निर्भर करता है |

भरने की सटीकता |

±1% |

वैकल्पिक भरने का आयतन |

10-100ml 30-300ml 50-500ml 100-1000ml 200-1500ml 500-2500ml 1000-5000ml |

पैकेज:

मानक निर्यात कार्टन पैकिंग.

डिलीवरी समय:

ऑर्डर की पुष्टि करने के बाद 3-20 दिन, विस्तृत डिलीवरी तारीख को उत्पादन सीज़न और ऑर्डर मात्रा के अनुसार तय किया जाना चाहिए।