Jiang powder processing line Specially designed for food factories and seasoning workshops

The ginger powder processing line is specially designed for food processing, agricultural product deep processing, and seasoning production scenarios. Its core features include a 270° rotating grinding structure and precise grinding inclined design: not only does it ensure uniform and error-free crushing of ginger pieces, with excellent grinding effect, but it also makes it convenient and residue-free to pour out the powder with the inclined angle, significantly improving processing efficiency; it supports large-scale continuous processing and can easily meet the large-scale production needs of factories with high output. The entire machine is made of chrome-plated stainless steel, which combines hygiene safety and corrosion resistance, ensuring the stable performance of the equipment over the long term and reducing maintenance costs. During the processing, it can lock in the nutritional value of ginger powder to the greatest extent, and the ground powder produced is fine, high-quality, and of high nutritional value, widely applicable in food factories, seasoning processing workshops, agricultural product cooperatives, etc., helping to quickly achieve standardized and efficient production of ginger powder.

- Overview

- Product Advantages

- Product Feature

- Basic Information

- Product Details

- Recommended Products

Jiang powder processing line Specially designed for food factories and seasoning workshops

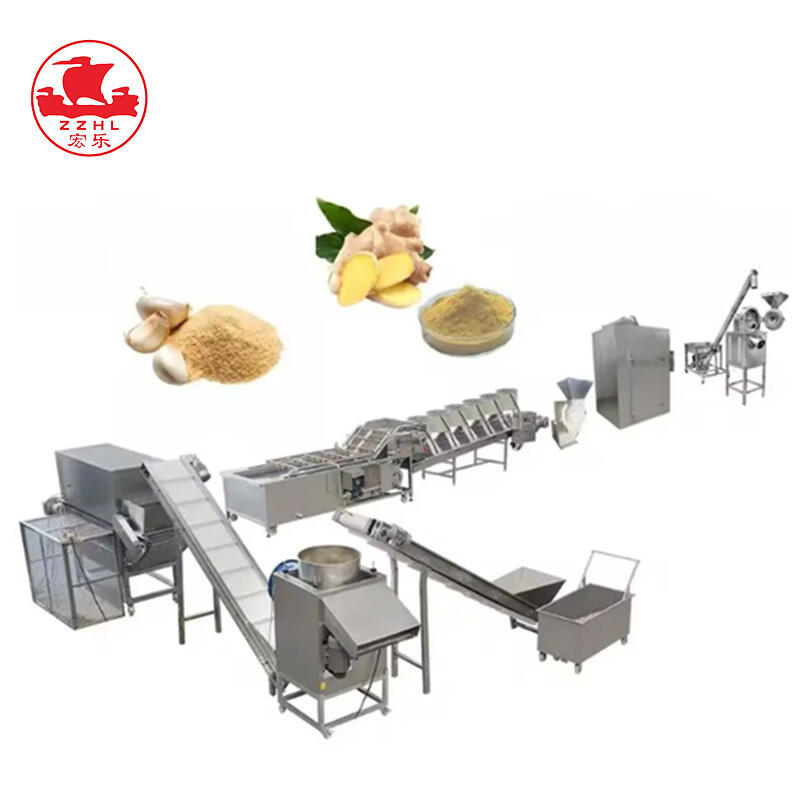

The ginger powder processing line uses ginger as raw material and processes it into ginger powder through a series of manufacturing techniques, including cleaning, peeling, slicing, drying, and grinding. This product caters to the culinary requirements of diverse households, restaurants, and food processing plants.

Transforming ginger into ginger powder can enhance the added - value of ginger in the ginger cultivation industry. It also mitigates losses caused by price fluctuations and reduces storage and transportation costs. Undoubtedly, it represents the optimal choice for the ginger powder business!

Product Advantages

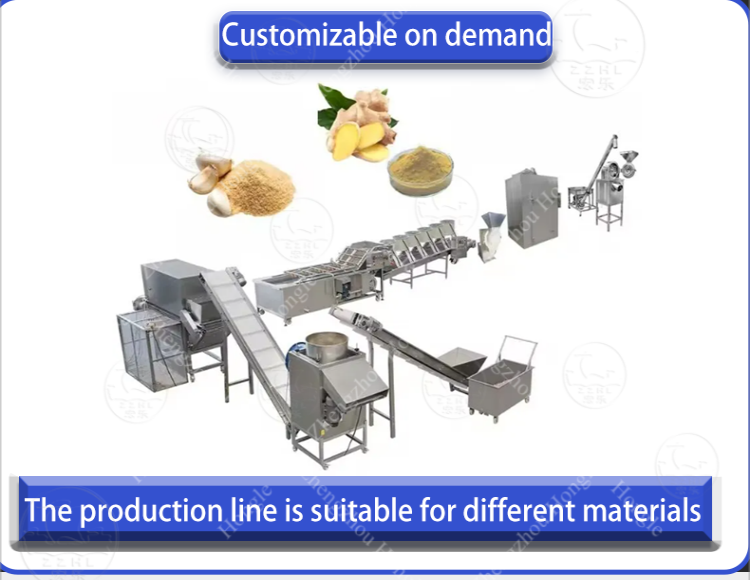

Can be customized.

Configure different production lines according to customer output requirements.

The ginger powder production line is fully automatic and semi-automatic, and customers can choose according to their own needs.

Easy to operate.

The ginger powder production line is easy to install and can be used after connecting to the power supply. It is reliable to use and easy to disassemble.

Ginger powder is of high quality.

The dryer adopts medium and low temperature drying. After drying, the original color and nutrients of ginger can be completely retained.

Flexible heat source selection of dryer.

Coal, wood chips, natural gas, diesel, propane, electricity etc.

Wide range of applications.

Most of the machines in the line are not only suitable for ginger, but also for other fruits and vegetables.

Product Feature

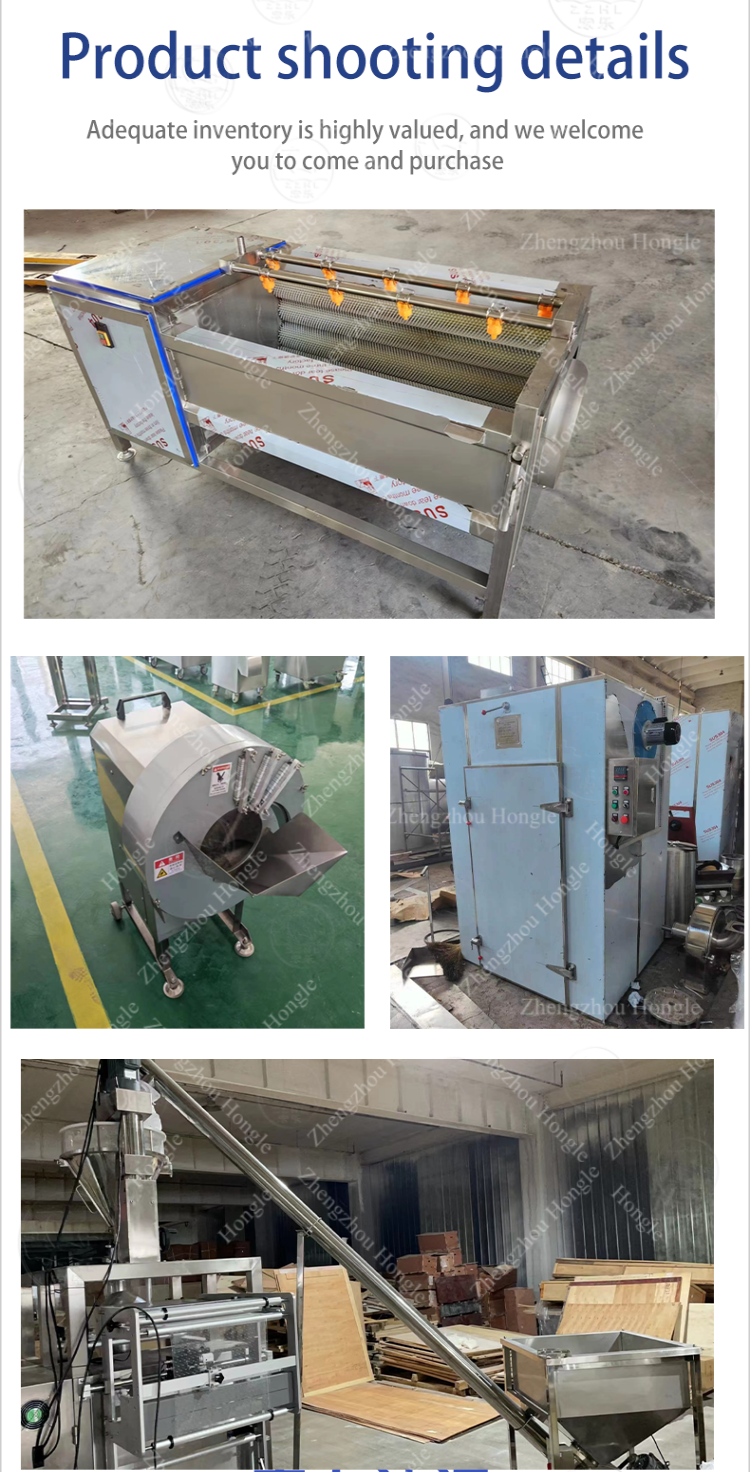

Brush cleaning machine

Thoroughly cleaned,with peeling function to save manpower.

Microtome

Slice evenly, easy to operate, effectively improve work efficiency.

Dryer

Effective dehydration, convenient and hygienic.

Crusher

Material can be customized according to needs to meet different requirements.

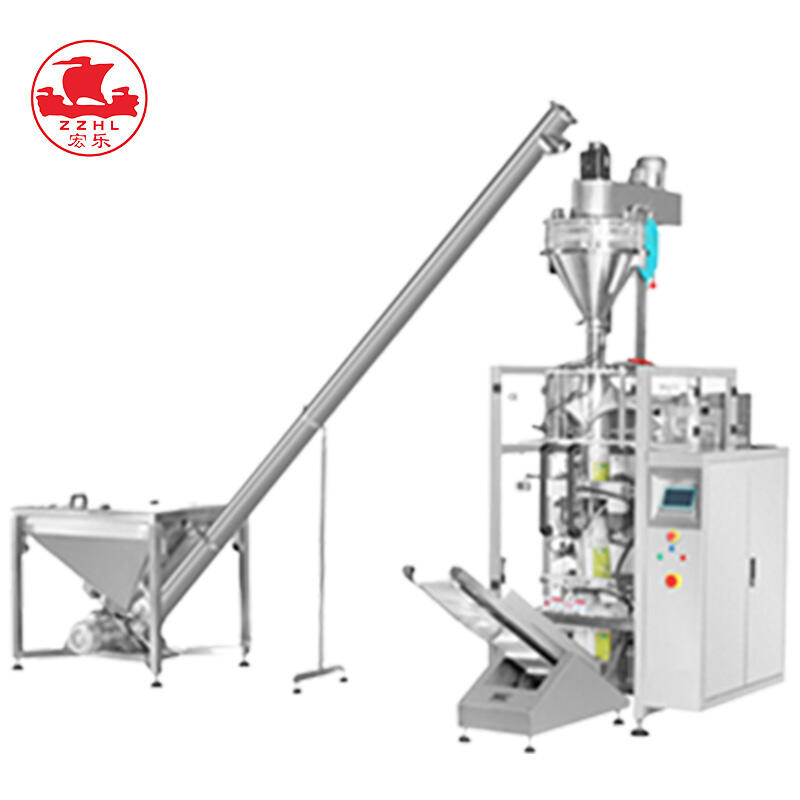

Powder packaging machine

Equipment that can achieve precise metering, automatic filling, sealing, and complet powder packaging for easy storage, transportation, and sales.

Basic Information

| Dryer | 50-1000kg/H | Working Type | Batch Oven Dryer / Continuous Mesh Belt Dryer |

| Voltage | 380V | Input Capacity | 50-1000kg/H |

| Power | Customzied as Per Your Production Line | Input Material | Fresh Ginger |

| Customized | Customized | Output Material | Ginger Powder / Dried Ginger Slices |

| Machine Name | Ginger Process Line | Transport Package | in Nude/Ply-Wood Box |

| Machine Process | Ginger Washing, Peeling, Slicing, Drying, Grinding | Specification | Customized as per the machine |

| Heating Source | Electric, Gas, Wood, Oil, Steam, Coal | Trademark | Hongle machinery |

| Production Capacity | 50-1000kg/H | Origin | China |

Product Details