F1 High Quality Egg Washing and Grading Machine Automatic Dirty Chicken Quail Duck Egg Wash Washer

- Overview

- Recommended Products

High quality egg washing machine egg washing and grading machine duck egg washing machine

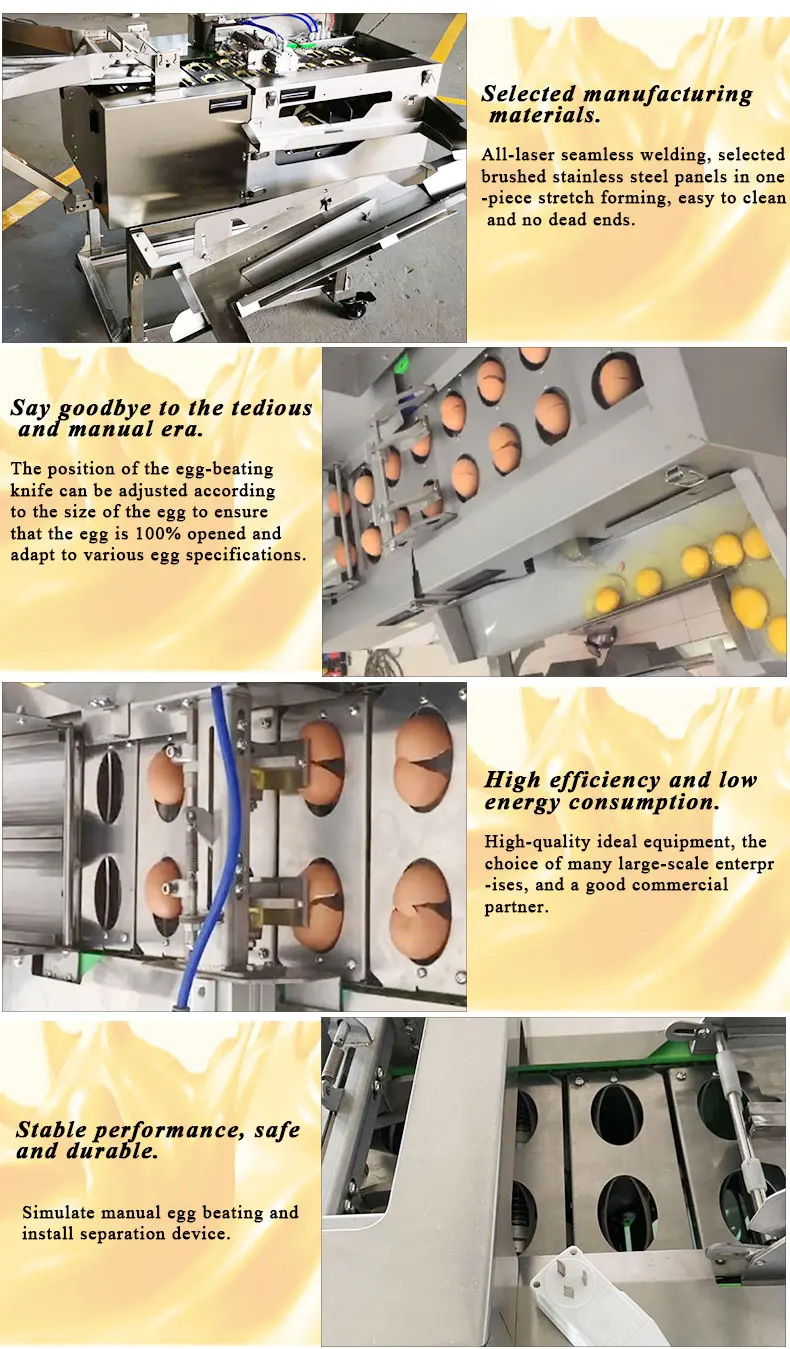

Product Description

Description of egg cleaning machine

Eggs cleaning grade production line can be automatically feeding egg, warm water spray, strong quickly scrub, dry wind quickly,

injection (printing), ultraviolet radiation sterilization, optical inspection, grading.

A complete set of equipment for 304 stainless steel material.Also can according to user requirements

injection (printing), ultraviolet radiation sterilization, optical inspection, grading.

A complete set of equipment for 304 stainless steel material.Also can according to user requirements

Features of egg cleaning machineSpecial professional egg cleaning washing machine,

Conveying egg by single row in water, save manpower, enhance efficiency

Special nylon brush with fine elasticity three-sections six-branched cleaning, abrasion proof, clean, quick

The salted duck egg, ash-egg will be smooth, nice, economic and practical after eggshell washed

Conveying egg by single row in water, save manpower, enhance efficiency

Special nylon brush with fine elasticity three-sections six-branched cleaning, abrasion proof, clean, quick

The salted duck egg, ash-egg will be smooth, nice, economic and practical after eggshell washed

Model |

HL-ES1 |

Capacity |

2700-3200pcs/h |

Voltage |

220V |

Power |

0.3kw |

Weight |

115kg |

Size |

1750*1150*850mm |

Production name |

HL-ES2 |

Voltage |

220V |

Power |

500W |

Capacity |

4500-5400pcs/h |

Machine material |

Stainless steel |

Machine size |

1700*1100*1100mm |

Machine weight |

140kg |

Model |

HL-ES3 |

Capacity |

8100-9500pcs/h |

Voltage |

220V |

Power |

0.3kw |

Weight |

150kg |

Size |

1750*1150*970mm |

Model |

HL-ES4 |

Capacity |

10800-12000pcs/h |

Voltage |

220V |

Power |

0.3kw |

Weight |

160kg |

Size |

1750*1150*1130mm |

Related Products

Features of Mayonnaise making production line

Machine: Emulsifying homogenizer

Raw Material: yolk powder/salad oil /vinegar/water

1. The material is preheated and stirred in the water and oil pot, and then can be directly sucked into the homogenization pot

under vacuum through the conveying pipeline.

2. In the homogenizing pot, the material passes through the PTFE scraper (the scraper always caters to the shape of the pot and

sweeps away the sticky materials on the wall) in the homogenizing pot to continuously produce new interfaces, and then passes

through the frame agitator to cut, Compress, fold, stir, mix and flow down to the homogenizer below the pot, and then through

the strong shearing, impact, turbulence and other processes generated between the high-speed rotating rotor and the stator,

the material is sheared The slit is cut and quickly broken into particles of 200nm-2μm. Material granulation, emulsification,

mixing, homogenization, dispersion, etc. can be completed in a short time. Since the homogenizer is in a vacuum state, the

bubbles generated during the mixing process of the material are drawn away in time. After the homogenization is finished,

raise the homogenization pot lid, and rotate the dumping hand wheel to make the materials in the pot discharge into the

container outside the pot.

3. The heating temperature of the homogenizing pot is set and adjusted by the temperature controller on the control panel; the

homogenizing stirring and the paddle stirring can be used separately; they can also be used at the same time; the length of

the homogenizing stirring time is determined by the user according to the material properties grasp.

1. The material is preheated and stirred in the water and oil pot, and then can be directly sucked into the homogenization pot

under vacuum through the conveying pipeline.

2. In the homogenizing pot, the material passes through the PTFE scraper (the scraper always caters to the shape of the pot and

sweeps away the sticky materials on the wall) in the homogenizing pot to continuously produce new interfaces, and then passes

through the frame agitator to cut, Compress, fold, stir, mix and flow down to the homogenizer below the pot, and then through

the strong shearing, impact, turbulence and other processes generated between the high-speed rotating rotor and the stator,

the material is sheared The slit is cut and quickly broken into particles of 200nm-2μm. Material granulation, emulsification,

mixing, homogenization, dispersion, etc. can be completed in a short time. Since the homogenizer is in a vacuum state, the

bubbles generated during the mixing process of the material are drawn away in time. After the homogenization is finished,

raise the homogenization pot lid, and rotate the dumping hand wheel to make the materials in the pot discharge into the

container outside the pot.

3. The heating temperature of the homogenizing pot is set and adjusted by the temperature controller on the control panel; the

homogenizing stirring and the paddle stirring can be used separately; they can also be used at the same time; the length of

the homogenizing stirring time is determined by the user according to the material properties grasp.

Equipment Application Of mayonnaise making line:

Emulsification is the action of a liquid uniformly dispersed in another liquid that is immiscible with tiny droplets.

Emulsification is a liquid-liquid interface phenomenon. Two immiscible liquids, such as oil and water, are divided into two layers in a container. In the emulsifier, the oil with low density is on the upper layer and the water with high density is on the lower layer. If an appropriate surfactant is added under strong stirring, the oil is dispersed in the water to form an emulsion. This process is called emulsification.

Emulsification is a liquid-liquid interface phenomenon. Two immiscible liquids, such as oil and water, are divided into two layers in a container. In the emulsifier, the oil with low density is on the upper layer and the water with high density is on the lower layer. If an appropriate surfactant is added under strong stirring, the oil is dispersed in the water to form an emulsion. This process is called emulsification.

Parameters:

MODEL |

MIXER POT |

WATER POT |

OIL POT |

HL-RHJ50 |

50L |

38L |

25L |

HL-RHJ100 |

100L |

60L |

45L |

HL-RHJ250 |

250L |

160L |

130L |

HL-RHJ350 |

350L |

250L |

200L |

HL-RHJ650 |

650L |

400L |

320L |

HL-RHJ1000 |

1000L |

650L |

500L |

HL-RHJ1300 |

1300L |

800L |

650L |

HL-RHJ2000 |

2000L |

1200L |

950L |

Application:

(1) Daily chemical and cosmetics industry:baby cream, shaving cream, cream shampoo, toothpaste, cold cream, sunscreen cream, face cleanser, moisture cream, detergent,shampoo etc

(2)Pharmacy industry:Emulsion, emulsifier, ointment, syrup etc

(3)Food industry:sauce, cheese, oral syrup, nutrient solution, infant food, chocolate, saccharine etc

(4)Chemical industry:latex, saponification, paint, resin, adhesives, lubricating agent etc

Pls kindly confirm as following (Thanks ):

1.What is your detail of made products ?

2.What is capacity of tank do you need ?

3.Which heating method do you need ?electric heating or steam heating

4.Which type of homogenizer do you need ?upper homogenizer or bottom homogenizer

5.Which control do you need ?PLC touch screen control or button control

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling

machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo,liquid saop ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

(2)Pharmacy industry:Emulsion, emulsifier, ointment, syrup etc

(3)Food industry:sauce, cheese, oral syrup, nutrient solution, infant food, chocolate, saccharine etc

(4)Chemical industry:latex, saponification, paint, resin, adhesives, lubricating agent etc

Pls kindly confirm as following (Thanks ):

1.What is your detail of made products ?

2.What is capacity of tank do you need ?

3.Which heating method do you need ?electric heating or steam heating

4.Which type of homogenizer do you need ?upper homogenizer or bottom homogenizer

5.Which control do you need ?PLC touch screen control or button control

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling

machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo,liquid saop ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

*If you can not open the links above on Alibaba APP on mobile phone, please use IE browser to visit our website:

https://chinafoodmachine.en.alibaba.com.

https://chinafoodmachine.en.alibaba.com.

Packing & Delivery

Our Company

Certifications

FAQ

Contact Me

Need more machine details or video ? Please contact us directly