Four Tipping Bucket Blanching Machine | 400kg/h for Vegetables, 8kW, SUS304 Steel, PLC Control

Industrial Four Tipping Bucket Blancher | 0.1-0.3MPa Steam, 400kg/h for Fruit Processing, Automatic Temperature Control

- Overview

- Product Features/Advantages

- Application Scenarios

- Product Parameters

- Packaging & Shipping

- Customer Feedback

- FAQ

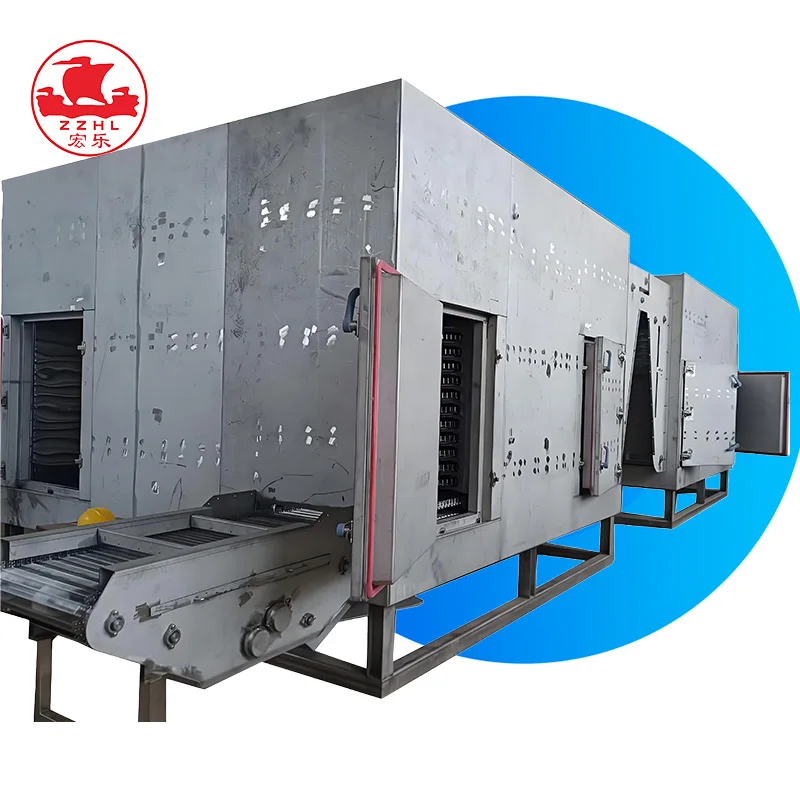

- Recommended Products

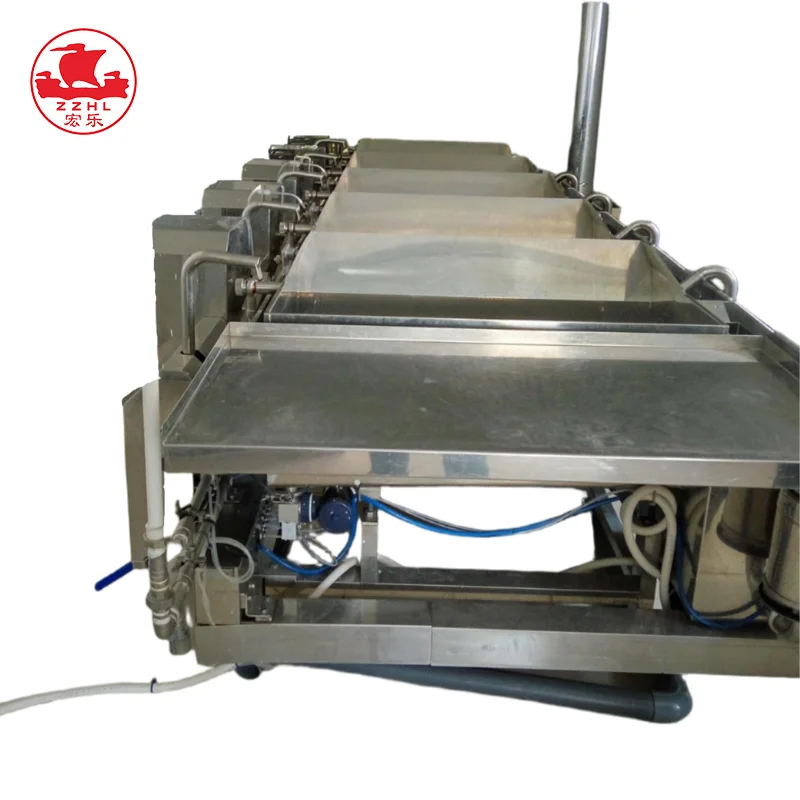

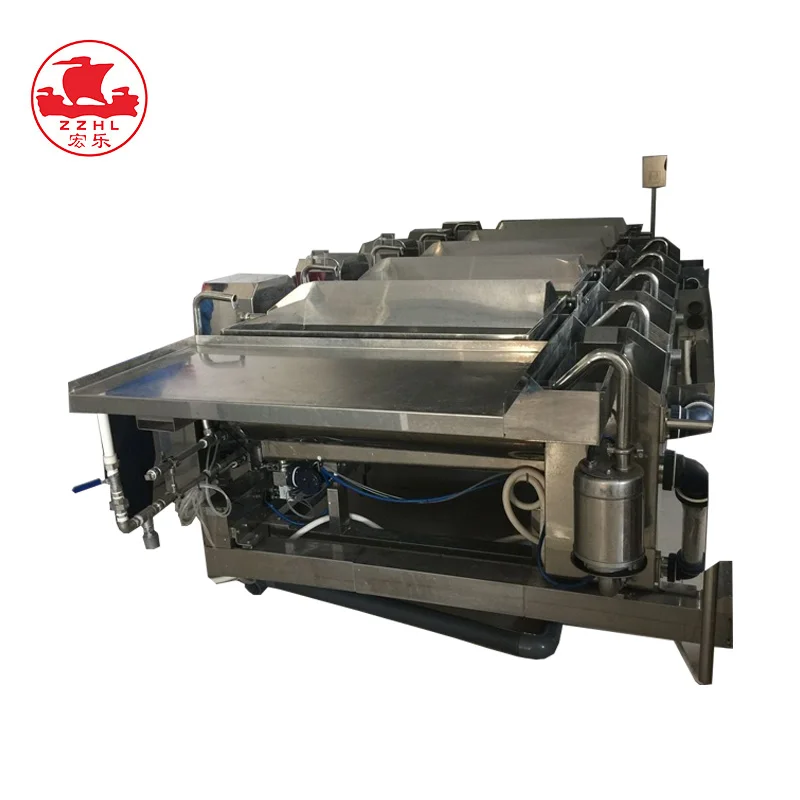

Four Tipping bucket blanching machine

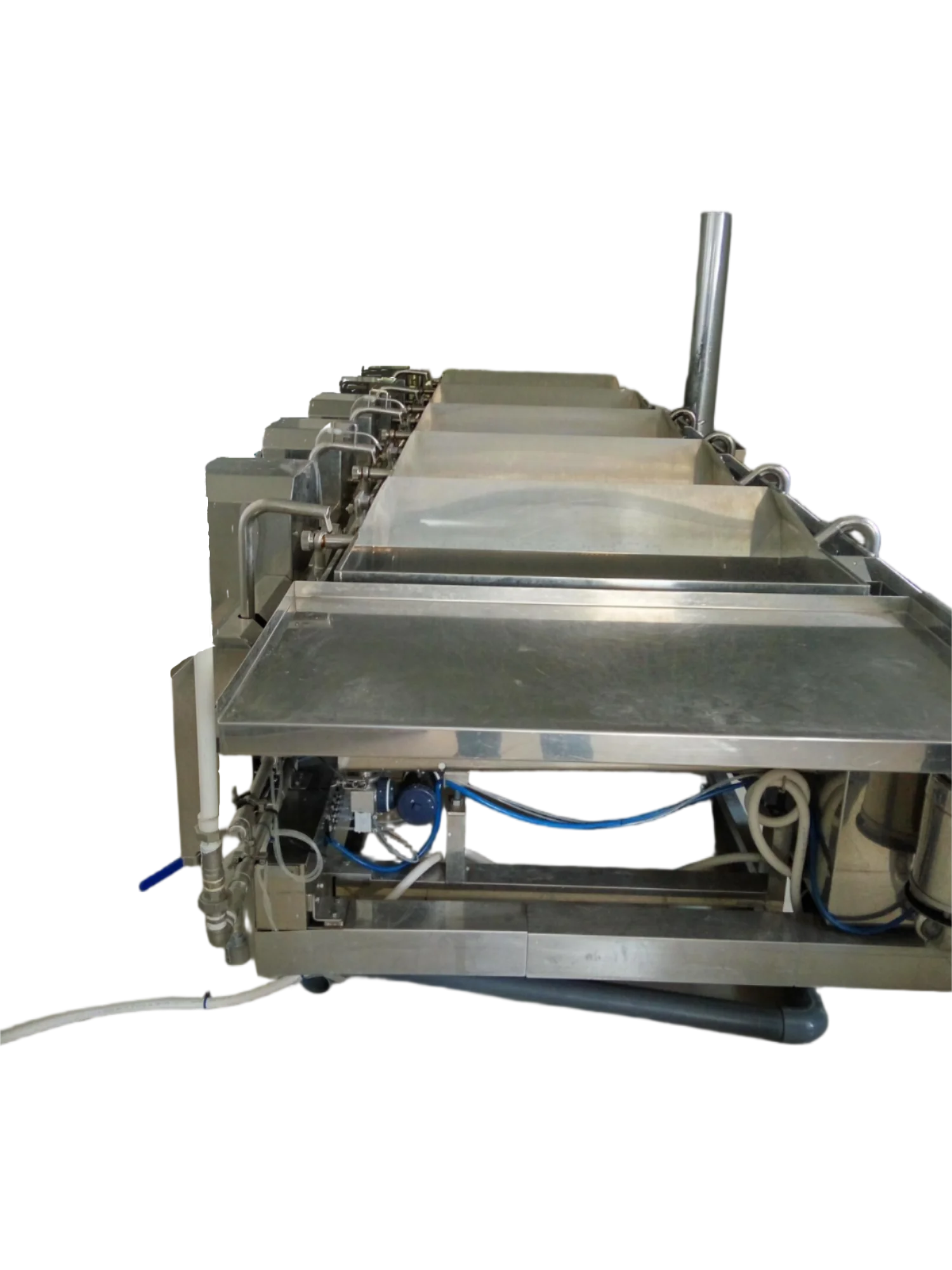

The Four Tipping Bucket Blanching Machine is a specialized industrial - grade equipment engineered for high - volume washing and blanching of agricultural products like vegetables and fruits. Its most distinctive feature lies in the four - tipping - bucket design, which enables continuous and efficient processing, doubling the productivity compared to single - bucket models. With a robust construction made entirely of SUS304 stainless steel, the machine guarantees durability and strict compliance with global food safety standards. Operating at 8kW power under 380V voltage, it can process up to 400kg of produce per hour, making it an ideal choice for large - scale food processing plants engaged in canning, freezing, or drying of vegetables and fruits. The machine utilizes steam with a pressure range of 0.1 - 0.3MPa and consumes 400kg of steam per hour, ensuring consistent and thorough blanching results for various food ingredients.

Quadruple - Bucket Efficiency:

The four tipping buckets work in rotation, allowing for seamless loading, washing, blanching, and unloading processes. This design significantly increases processing speed, reducing downtime and boosting overall productivity by up to 50% compared to traditional blanching machines, especially beneficial for high - volume vegetable and fruit processing.

Intelligent PLC Control:

Equipped with an advanced PLC control system, the machine automatically manages water inlet, water outlet, and temperature regulation. The built - in temperature sensor and display within the sterilization pot, integrated with the PLC, provide real - time and precise temperature monitoring, ensuring uniform blanching quality for every batch of agricultural products.

Food - Grade & Durable Build:

Constructed from high - quality SUS304 stainless steel, the machine resists corrosion and is effortless to clean, fully meeting international food hygiene requirements such as FDA and CE. While key components like motors, reducers, and pillow blocks are made of carbon steel for enhanced mechanical strength, ensuring long - term stable operation in food processing environments.

Efficient Pneumatic Valve System:

The pneumatically controlled water inlet and outlet valves offer rapid and reliable operation. This automation minimizes manual intervention, improves process control accuracy, and enhances the overall operational efficiency of the machine, crucial for continuous production lines of vegetables and fruits.

Resource - Conservation Design:

The innovative water recycling feature allows the water in the cooling tank to be reused in other processes, reducing water consumption by up to 40%. The unified drainage pipeline simplifies system management and maintenance, contributing to cost savings in food processing operations.

Superior Welding & Easy Maintenance:

The pipes adopt single - side welding with double - side forming technology, ensuring leak - proof and sturdy connections, which extends the equipment's lifespan. Moreover, its modular and detachable structure makes daily cleaning and maintenance a breeze, reducing labor costs and downtime for ongoing food production.

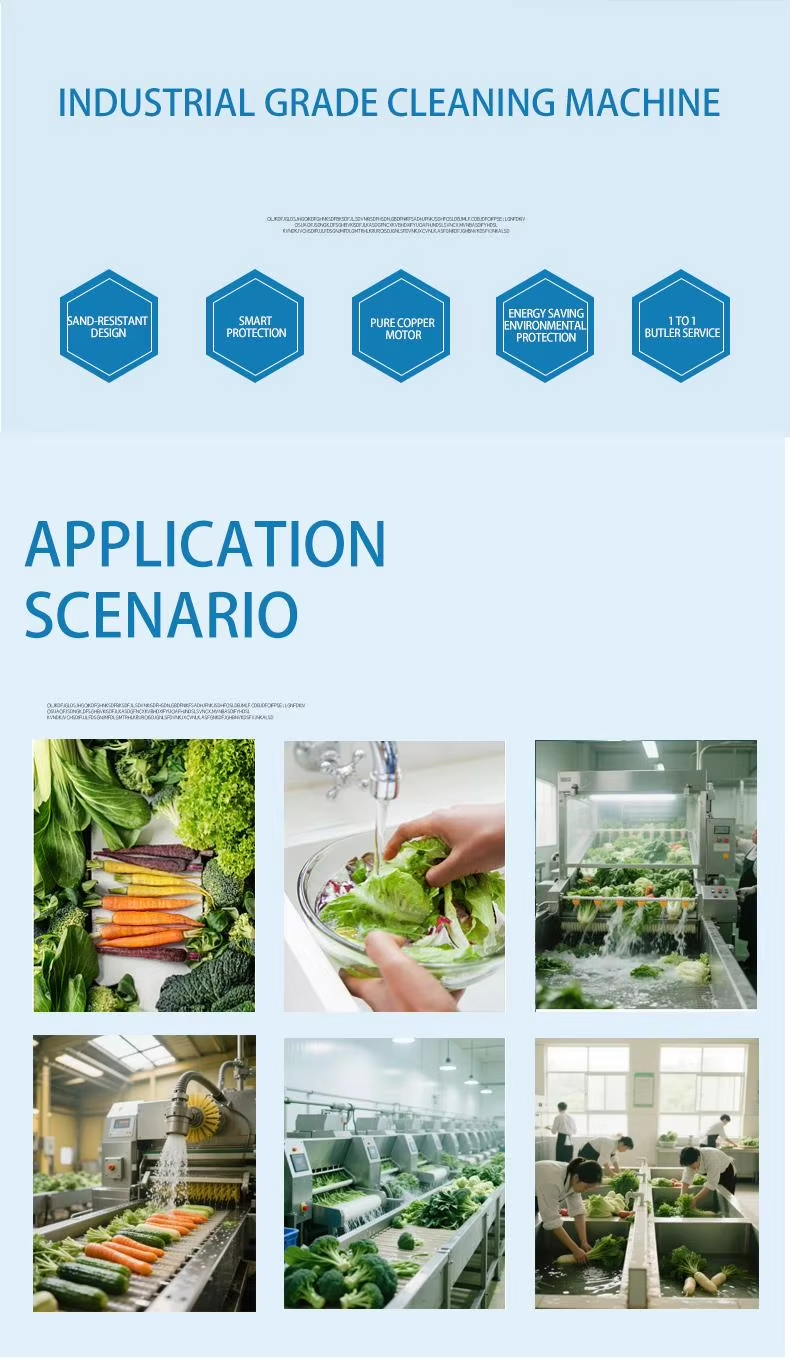

Large - Scale Vegetable Processors:

Ideal for blanching leafy greens, root vegetables, and cruciferous vegetables such as lettuce, carrots, and cauliflower. The four - bucket design ensures high - volume processing, maintaining the vegetables' color, texture, and nutritional value while eliminating impurities and reducing enzyme activity, essential for frozen vegetable production and canning.

Fruit Processing Enterprises:

Used for washing and blanching a variety of fruits like berries, stone fruits, and tropical fruits before further processing into jams, juices, dried fruits, or canned products. The consistent blanching provided by the machine ensures a uniform raw material quality for downstream production, crucial for fruit - based food manufacturing.

Canning and Preserving Industries:

Essential for preparing ingredients for canning and preserving. The FDPT - 4 Four Tipping Bucket Blanching Machine helps meet strict quality standards, extending the shelf life of canned and preserved products by effectively inactivating spoilage - causing enzymes in both vegetables and fruits, ensuring product safety and longevity.

Agricultural Product Aggregators and Processors:

Suitable for large - scale processing centers that handle diverse agricultural products. The machine's high capacity and versatility make it a valuable asset for efficiently washing and blanching harvested crops, enhancing product marketability and processing capacity in agricultural product pretreatment for various food industries.

| Item | Value |

| Core Components | MOTOR |

| Place Of Origin | China |

| Brand Name | Hongle |

| Warranty | 1 Year |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Applicable Materials | leafy greens, root vegetables, cruciferous vegetables |

| Voltage | 380V |

| Power | 8kw |

| Dimension(L*W*H) | 3927x1530x1000mm |

| Weight | 1000kg |

| Output | 400kg/h |

| Steam pressure | 0.1~0.3MPa |

| Steam consumption | 400kg/h |

PACKAGE

Standard export carton packing, fit for multiple handing and long distance marine shipping.

DELIVERY TIME

3-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

1) When can I get the price?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

2) How do you make your price?

We make the price according to our comprehensive costing. And our price will lower than the trade company because we are manufacture.You will get competitive price and better quality.

3) Can you guarantee your quality?

Of course. We are the manufacture factory. More important, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

4) How long does the whole procedure being worked out?

After you place a order,the production handling time is about 30-45 days. We need 7 days to prepare all the stuff then 30 days for manufacturing.

5) What about the transportation and delivery date?

Normally we use shipment to transprot the goods.It is about 25-40 days.It also denpends on which coutry and port you are. If there are some emergencies we can send the goods via air express, as long as you afford the traffic expense.