material or SS material

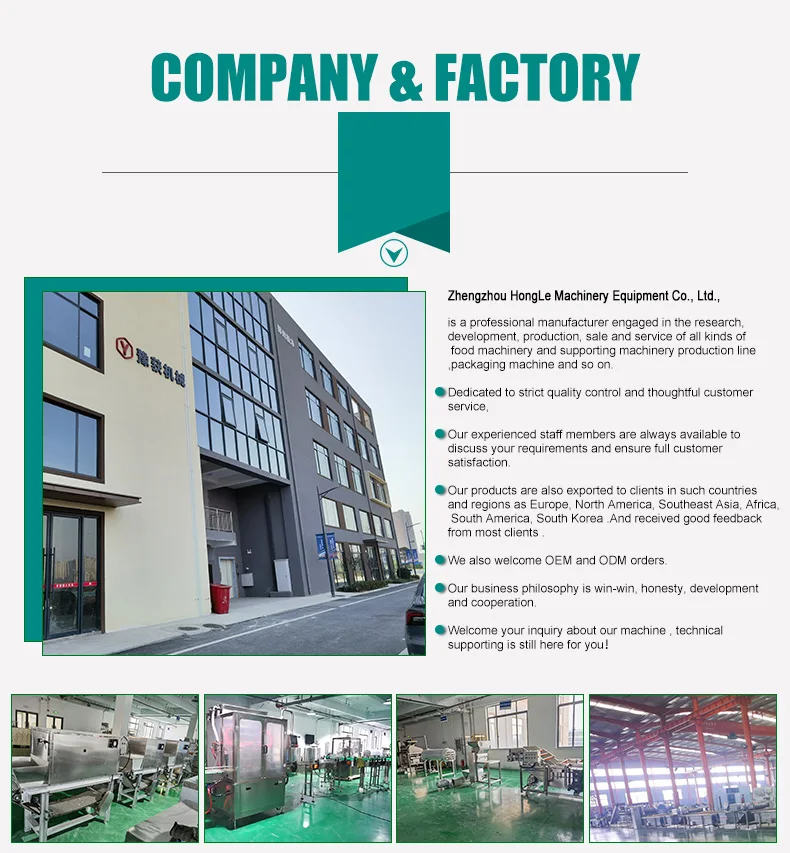

Full Automatic Aerosol Detergent Pesticides Automotive Carb Cleaner Filling Machine Production Line Maquina De Espuma En Aerosol

- Overview

- Recommended Products

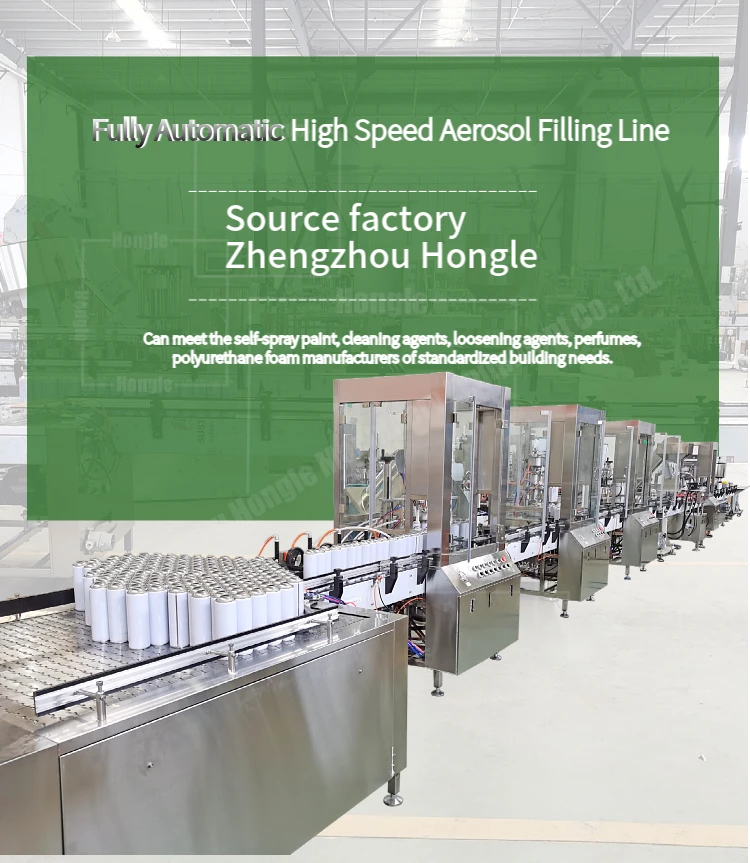

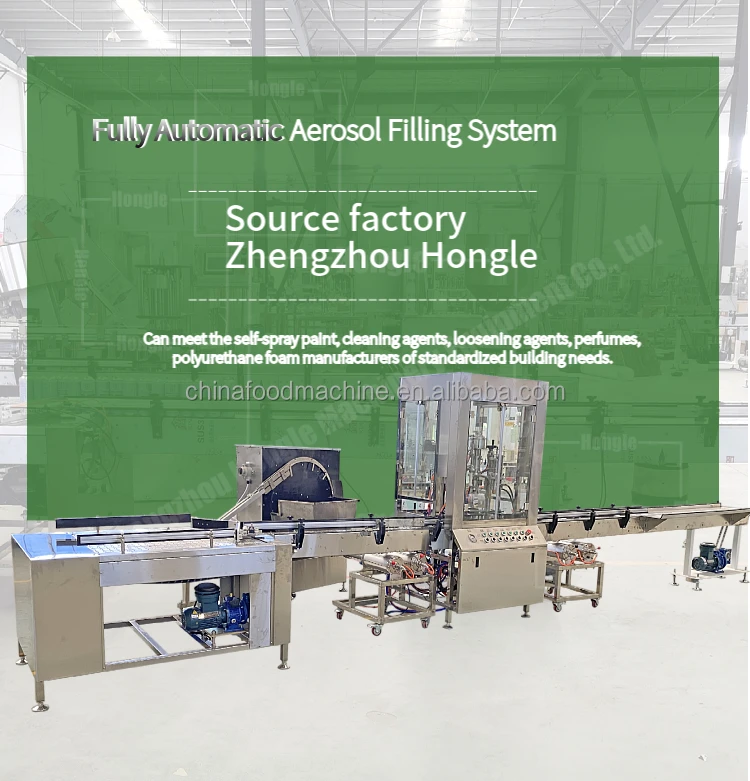

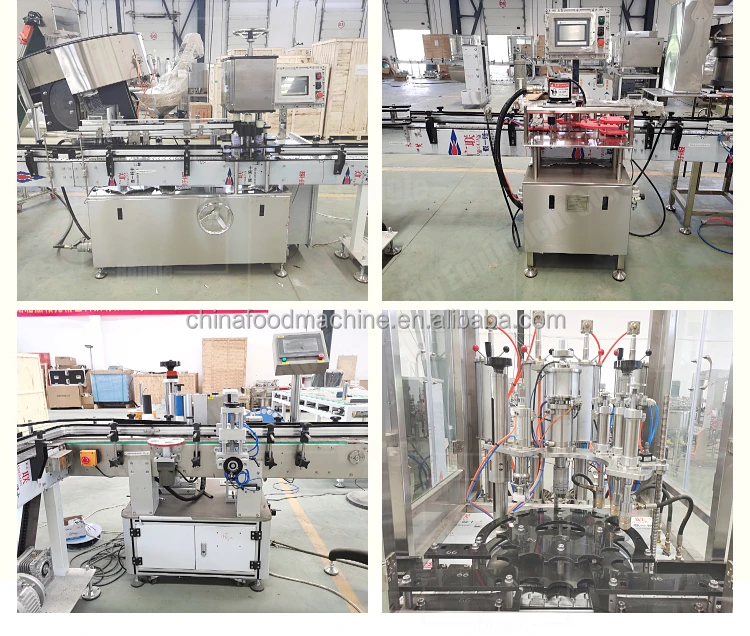

Fully Automatic Aerosol Filling Lines/ High speed Automatic Filling Lines

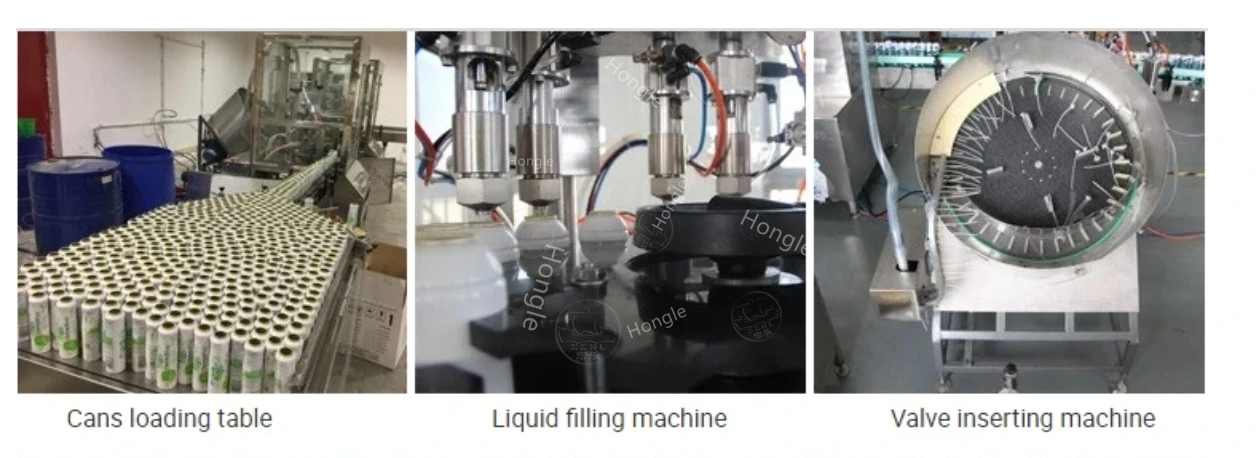

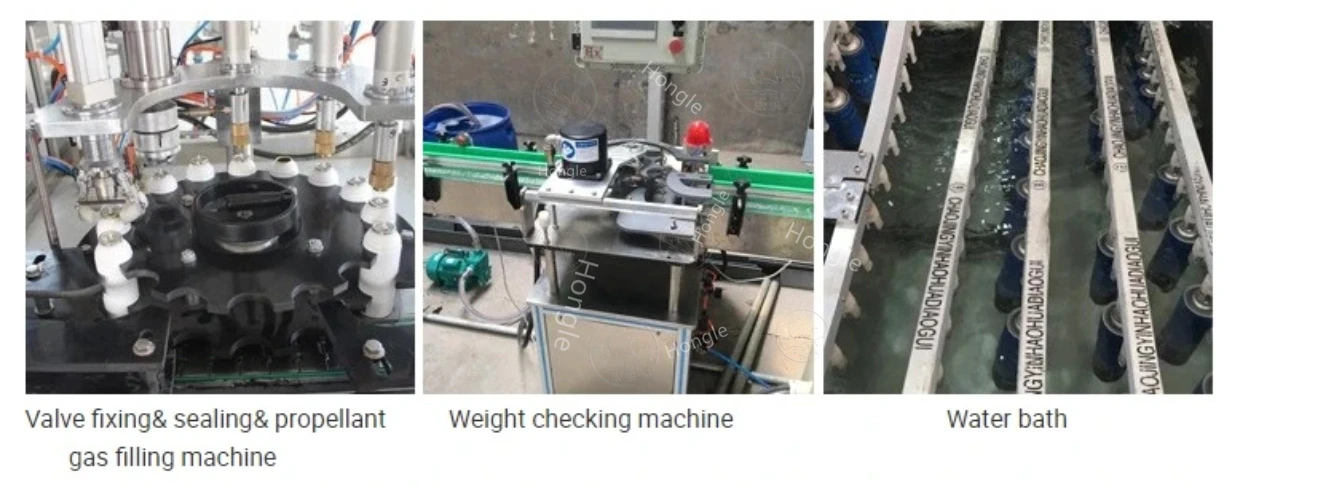

consist of cans arranging machine, rotary liquid filling machine, valve inserting machine, rotary crimping and gas filling machine, automatic weight checker, water bath, nozzle presser, cap presser, ink jet printer, packing table, etc. Propellants could be

LPG, DME, CO2, N2, compressed air, etc, widely applied in spray paint, air freshener, insecticide, body spray, cosmetics, food aerosols.

Working Process:

Cans loading table ----Liquid filling machine---- Valve inserting machine ---- Valve fixing& sealing& propellant gas filling machine ---- Weight checking machine ----Water bath tank---- Actuator pressing machine ----Cap pressing---- Ink jet printer ----other packing systems

material or SS material

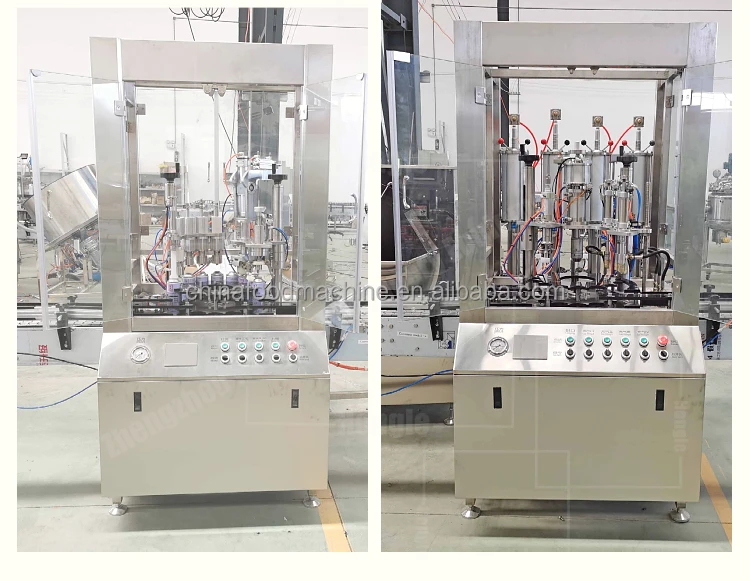

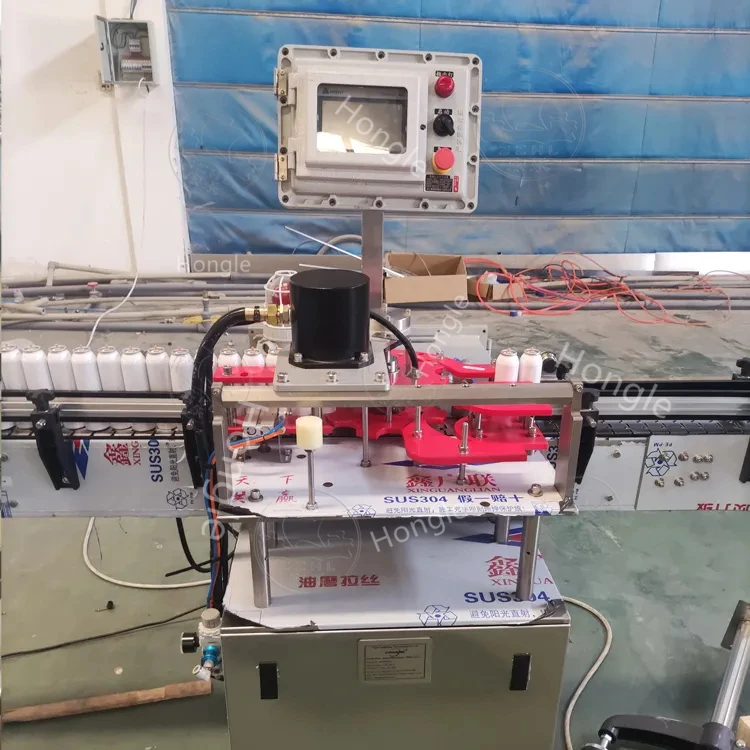

dosing cylinder, one way valve, filling head. The liquid filling heads we will use diving type no sparks, no dips. Coupled non can no fill feature. we use SMC or Festo brands which is durable. Pneumatic inlet at compressed air reservoir is G1'' female thread.

Product inlet is G1/2'' female thread*4 nos

the can automatically. It is an idea equipment for saving labor and improving production efficiency.The valve insert it consists

of 3 parts: valve sorting turntable, valve blowing part and valve placing part.This machine we will installed on the 4 heads

essence dropping machine table. Available for both aluminium valve and tin valve explosion-proof power driving,flexible for

different tube length.

sets of gas filling systems. Each gas filling system includes a piston cylinder and filling head. It also has 2 booster pumps and

a gas storage tank. The propellant gas is pressurized by the booster pump and filled in by liquid form, which is suitable for the

filling of liquefied gas, DME and other propellant gas. The designed stable working speed 60cpm based on 125ml (60grams) per

dosage per filling, speed should be reduced shall filling volume is greater. small dosage cylinder : 5-100ml , big dosage

cylinder: 30-300ml. Pneumatic inlet at compressed air reservoir is G1'' female thread.

Static deviation: 0G 5. Dynamic detection maximum deviation: ±1.0g 6. Air source: 0.5Mpa clean and stable air source 7. Production

capacity: ≦65 pcs/Min 8. Air consumption: 0.5m3/min 9. Applicable aerosol can diameter: ø35-ø70mm 10. Applicable aerosol can

height: 80-330mm 11. Packing dimension: 1130*750*1680mm 12. Weight: around 240kgs

power: 1kw Whole water bath system: 35KW 4. Production capacity:60cans/min on the base of immersion time 140seconds 5. Temperature

control accuracy: 55±2℃ 6. Air source: 0.5Mpa-0.6Mpa clean and stable air source 7. Air consumption: 0.3m3/min 8. Water bath main

body dimension: 1030*1050*2060mm water tank dimension: 3600*1150*1600mm 9. Weight : Around 1130kgs 10. We will also equipped with

hot wind drying system, safety net cover (stainless steel) safety outside guarding frame with organic glass.

replace the star wheel molds.1. Arranging mode: vibration hopper 2. Applicable aerosol can diameter: ø35-ø70mm 3. Applicable

aerosol can height: 80-330mm 4. Production capacity: ≦80CPM 5. Air source: 0.5Mpa clean and stable air source

automation, convenient operation, safe and reliable, it is the ideal choice for the manufacturers of aerosol cans.1. Arranging

mode: vibration hopper 2. Applicable aerosol can diameter: ø35-ø70mm 3. Applicable aerosol can height: 80-330mm 4. Production

capacity: ≦65CPM 5. Air source: 0.5Mpa clean and stable air source 6.Air consumption: 0.9m3/min 7. With function: No caps, less

cap, full caps, machine stop