is engaged in the development, design, manufacture and sale of food processing machinery. over the years adopts many new ideas, absorbs a wide range of advanced technologies worldwide as well as excellent processing and testing equipment, and takes a reliable strict quality guarantee system and an important after-sales service system to win customer's trust in the industry.

- Overview

- Recommended Products

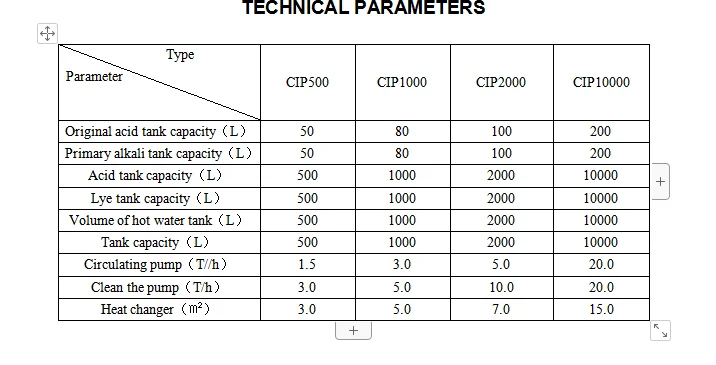

Technical parameters:

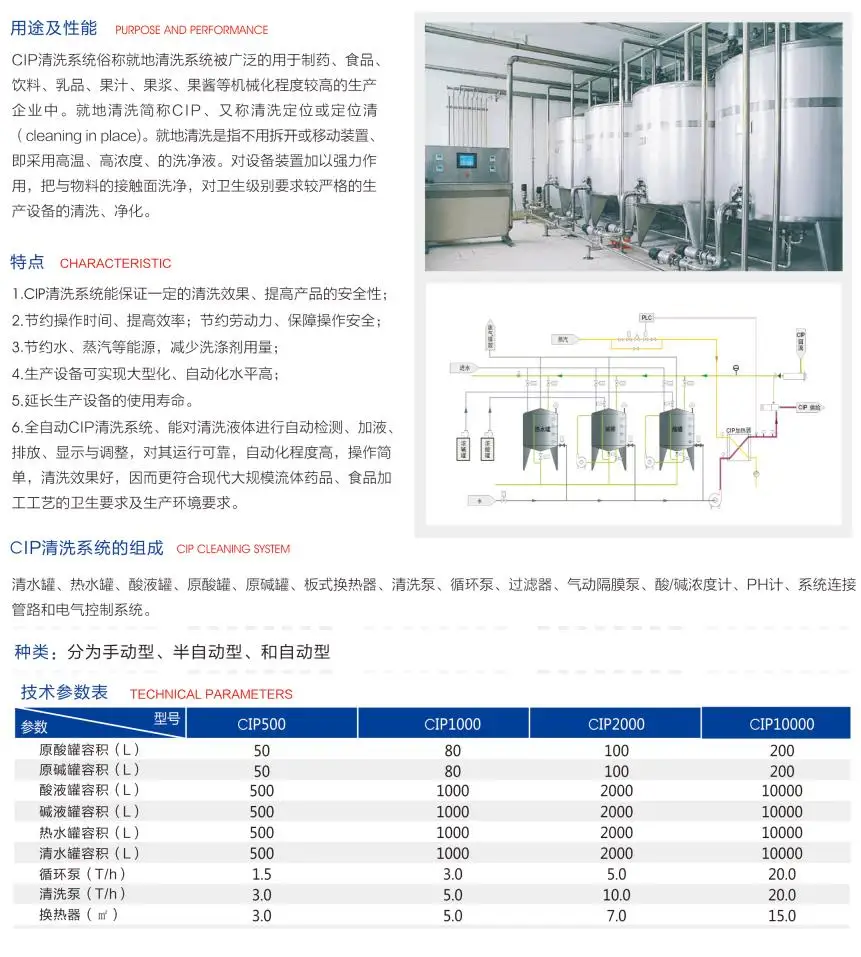

PURPOSE AND PERFORMANCE:

CIP cleaning system commonly known as on-site cleaning system is widely used in pharmaceutical, food, beverage, dairy, fruit juice, pulp, jam and other mechanized production enterprises. Cleaning in place is short for CIP, also known as cleaning in place.

On-site cleaning is not to disassemble or move the device, that is, the use of high temperature, high concentration of cleaning liquid. It has a strong effect on the equipment and device to clean the contact surface with the material, and to clean and purify the production equipment with strict hygienic level requirements.

CIP CLEANING SYSTEM

Clean water tank, hot water tank, acid tank, acid tank, alkali tank, plate heat exchanger, cleaning pump, circulation pump,

filter, pneumatic diaphragm pump, acid/alkali concentration juice, PH meter, system connection pipe and electrical control system.

PACKAGE:

Standard export carton packing.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

Zhengzhou hongle machinery & equipment co.ltd