ในยุคที่ผู้บริโภคมีความระมัดระวังเกี่ยวกับความปลอดภัยของอาหารและความสะอาดมากขึ้น ผู้ผลิตไข่เผชิญกับความท้าทายสำคัญในการรับประกันคุณภาพด้านสุขอนามัยของไข่แต่ละฟอง ไข่มักจะมีสิ่งสกปรก เชื้อแบคทีเรีย และสารปนเปื้อนอื่น ๆ บนพื้นผิว การพัฒนาโซลูชันการล้างที่มีประสิทธิภาพและสะอาดจึงกลายเป็นประเด็นสำคัญสำหรับการเติบโตของอุตสาหกรรม

ขอแนะนำสายการผลิตล้างและแปรรูปไข่อัตโนมัติเต็มรูปแบบของเรา ด้วยเทคโนโลยีอัตโนมัติขั้นสูง ระบบดังกล่าวไม่เพียงแต่เพิ่มประสิทธิภาพการผลิตอย่างมหาศาล แต่ยังรับประกันความสะอาดและความปลอดภัยจากเชื้อโรคของไข่แต่ละฟอง ทำให้ผลิตภัณฑ์ของคุณโดดเด่นในตลาดที่มีการแข่งขันสูง

สายการผลิตของเราประกอบไปด้วยการออกแบบอัตโนมัติเต็มรูปแบบ ซึ่งช่วยลดขั้นตอนทั้งหมดตั้งแต่การเก็บไข่ การคัดขนาด ไปจนถึงการทำความสะอาด การอบแห้ง และการแพ็ก ด้วยการทำงานอัจฉริยะในทุกขั้นตอน ทำให้สามารถลดต้นทุนแรงงานได้อย่างมาก โดยสามารประมวลผลไข่ได้หลายหมื่นฟองต่อชั่วโมง ช่วยให้มั่นใจในการผลิตปริมาณมากและสนับสนุนให้ธุรกิจขยายกำลังการผลิตได้

-

การโหลดไข่อัตโนมัติ : เพื่อการผสานรวมที่ราบรื่นสำหรับการดำเนินงานขนาดใหญ่

-

การโหลดไข่มือ动 : ตัวเลือกที่ยืดหยุ่นสำหรับการตั้งค่าขนาดเล็กหรือความต้องการเฉพาะ

-

กระบวนการล้างไข่แบบอัตโนมัติเต็มรูปแบบ : จัดการทุกด้านของการแปรรูปไข่อย่างง่ายดาย

ระบบทำความสะอาดแบบนวัตกรรมของเราผสานการขัดถูอย่างอ่อนโยนกับการฉีดน้ำอัจฉริยะ วิธีนี้สามารถกำจัดคราบสกปรก ฝุ่น และแบคทีเรียบนผิวไข่อย่างมีประสิทธิภาพ ในขณะเดียวกันก็ปกป้องเปลือกไข่ที่บอบบาง ไม่ว่าจะเป็นการปนเปื้อนที่หนักแค่ไหน ระบบของเราสามารถจัดการได้ ทำให้แต่ละฟองของไข่สะอาดหมดจดและสมบูรณ์

การดำเนินงาน : เพียงเทตะกร้าหรือกล่องของไข่ไก่หรือไข่เป็ดลงในอ่างล้างจานทั้งหมด ลูกกลิ้งลำเลียงจะช่วยนำไข่เข้าสู่ส่วนของลูกกลิ้งขน ส่วนนี้ลูกกลิ้งขนจะทำความสะอาดไข่อย่างละเอียด ไข่ที่สะอาดแล้วจะถูกปล่อยออกและคัดแยกเพื่อนำไข่ที่บกพร่องออกไป ไข่ที่ผ่านการตรวจสอบแล้วจะถูกลำเลียงโดยสายพานไปยังเครื่องบรรจุหรืออุปกรณ์ต่อเนื่องอื่นๆ ตามที่กำหนด

-

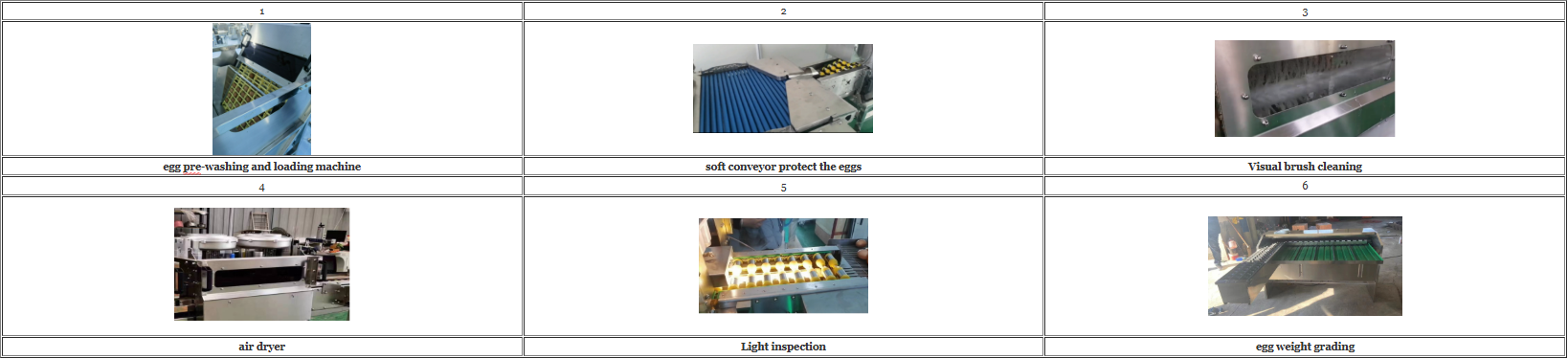

เครื่องล้างและโหลดไข่เบื้องต้น : เริ่มกระบวนการล้างอย่างมีประสิทธิภาพ

-

สายพานลำเลียงแบบนุ่ม : ปกป้องไข่ระหว่างการขนส่ง ป้องกันความเสียหาย

-

การทำความสะอาดแปรงแบบมองเห็นได้ : 保证清洗彻底,具有可见的擦洗动作

-

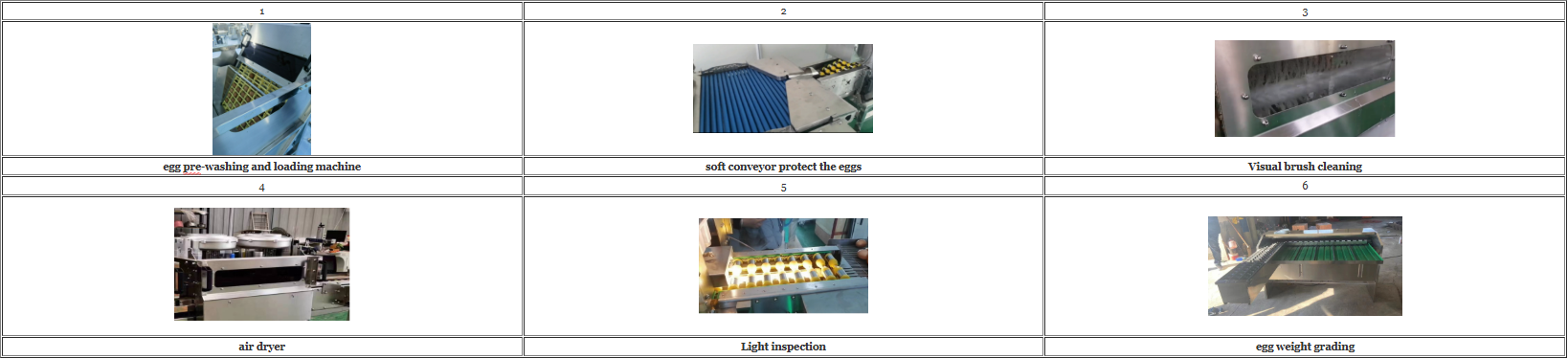

เครื่องอบแห้งอากาศ : ทำให้ไข้แห้งอย่างรวดเร็วและมีประสิทธิภาพหลังจากการล้าง

-

การตรวจสอบแสง : ตรวจจับข้อบกพร่องหรือสิ่งปนเปื้อนภายในไข่

-

การแบ่งเกรดตามน้ำหนักของไข่ : แยกไข่ตามน้ำหนักเพื่อรักษาคุณภาพของผลิตภัณฑ์ให้สม่ำเสมอ

-

เครื่องแยกไข่ขาวและไข่แดง : ฟีเจอร์เสริมสำหรับความต้องการในการแปรรูปเพิ่มเติม

ออกแบบโดยคำนึงถึงสุขอนามัยระดับอาหารที่เข้มงวด สายการผลิตการทำความสะอาดของเราปฏิบัติตามมาตรฐานสุขอนามัยระหว่างประเทศ ออปเตอร์เรชันแบบอัตโนมัติลดการสัมผัสของมนุษย์ลงอย่างมีประสิทธิภาพ ทำให้ลดความเสี่ยงของการปนเปื้อนครั้งที่สองได้อย่างมีประสิทธิภาพ ซึ่งรับประกันว่าไข่ไม่เพียงแต่สะอาดเท่านั้น แต่ยังสอดคล้องกับข้อกำหนดด้านความปลอดภัยของอาหารในหลายประเทศ

สายการผลิตการทำความสะอาดและการแปรรูปไข่ของเราได้รับการออกแบบโดยคำนึงถึงประสิทธิภาพในการประหยัดพลังงาน มันลดการใช้น้ำและการใช้ไฟฟ้าลงอย่างมาก ซึ่งช่วยลดต้นทุนการดำเนินงาน การใช้วัสดุและกระบวนการที่เป็นมิตรต่อสิ่งแวดล้อมช่วยให้อุปกรณ์มีเสถียรภาพและความน่าเชื่อถือในระยะยาว

ไม่ว่าคุณจะเป็นธุรกิจขนาดใหญ่ที่แปรรูปไข่ หรือฟาร์มขนาดเล็กถึงกลาง สายการผลิตอัตโนมัติเต็มรูปแบบของเราเสนอวิธีแก้ปัญหาที่เหมาะสม มันสามารถปรับตัวให้เข้ากับความต้องการในการผลิตที่หลากหลาย ช่วยให้ธุรกิจเพิ่มประสิทธิภาพการผลิต ลดต้นทุน และเพิ่มคุณภาพของผลิตภัณฑ์ ทำให้มีความได้เปรียบในตลาด

โรงงานแปรรูปไข่รายใหญ่ได้เห็นผลลัพธ์ที่น่าประทับใจหลังจากใช้สายการผลิตล้างไข่ของเรา ประสิทธิภาพการผลิตของพวกเขาเพิ่มขึ้น 40% คุณภาพของไข่ดีขึ้นอย่างมาก และส่วนแบ่งตลาดขยายตัวอย่างมีนัยสำคัญ เช่นที่ผู้จัดการโรงงานกล่าวไว้ว่า "สายการล้างอัตโนมัติได้เปลี่ยนเกมให้เรา มันไม่เพียงแต่ลดต้นทุนแรงงานของเราอย่างมาก แต่ยังเพิ่มประสิทธิภาพการผลิตและความสะอาดของไข่ ขับเคลื่อนการเติบโตของเรา"

ด้วยความคาดหวังของผู้บริโภคที่เพิ่มขึ้นในเรื่องคุณภาพอาหารและความสะอาด เครื่องล้างไข่และสายการผลิตแบบอัตโนมัติเต็มรูปแบบของเราเป็นหุ้นส่วนที่เหมาะสมสำหรับธุรกิจของคุณ ไม่ว่าคุณจะต้องการเพิ่มประสิทธิภาพการผลิต ลดต้นทุน หรือเพิ่มความสามารถในการแข่งขันของผลิตภัณฑ์ เราพร้อมนำเสนอวิธีแก้ปัญหาเฉพาะตามความต้องการของคุณ

ติดต่อเราตอนนี้เพื่อดูรายละเอียดเพิ่มเติมเกี่ยวกับสายการผลิตเครื่องล้างไข่ของเรา! เมื่อคุณซื้อสายการผลิตของเรา คุณจะได้รับประโยชน์จากระบบทำความสะอาดประสิทธิภาพสูง นอกจากนี้ยังมีบริการติดตั้งเครื่องจักรและการฝึกอบรมทางเทคนิคฟรี เพื่อรับรองกระบวนการผลิตที่ราบรื่น มีประสิทธิภาพ และปลอดภัย

โซลูชันการทำความสะอาดและแปรรูปไข่แบบอัตโนมัติและฉลาดของเราจะทำให้ไข่ของคุณเป็นตัวเลือกอันดับหนึ่งในตลาด สร้างความไว้วางใจให้กับผู้บริโภค เส้นการผลิตการทำความสะอาดและแปรรูปไข่อัตโนมัติเต็มรูปแบบนี้เป็นการลงทุนที่ดีที่สุดสำหรับการเพิ่มประสิทธิภาพการผลิต รับประกันความปลอดภัยทางอาหาร พัฒนาคุณภาพของผลิตภัณฑ์ และเสริมสร้างความสามารถในการแข่งขันในตลาด

ข่าวเด่น

ข่าวเด่น