Walnut Green Husk Peeling Machine | Industrial-Grade Dehuller for High Efficiency

Commercial Walnut Husk Peeling Machine | Suitable for Fresh & Semi-Dried Walnuts

- Overview

- Product Advantages

- Application Scenarios

- Technical Parameters

- Detailed Information

- Recommended Products

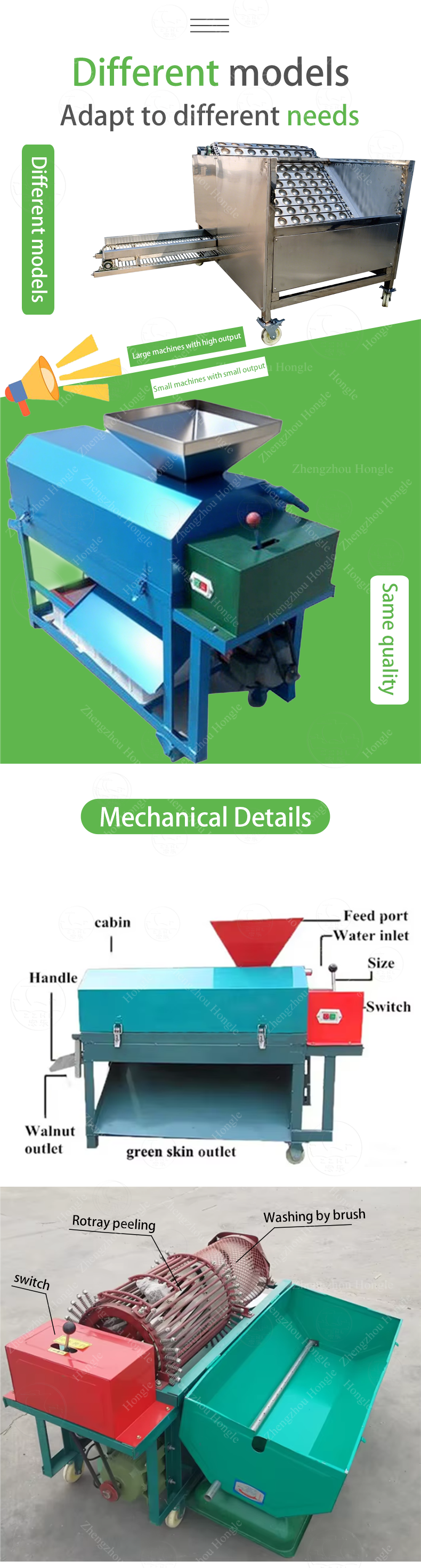

The Walnut Husk Removing Machine is a specialized device designed to peel the green, outer husk from fresh or semi-dried walnuts— a key pre-processing step before shelling, cleaning, or storage. It adopts a combination of mechanical friction and gentle extrusion: walnuts are fed into a rotating drum or roller chamber, where soft rubber or plastic blades rub against the green husk to separate it from the hard shell. The machine also features a built-in separation system (via airflow or conveyor) that sorts peeled walnuts from the removed husk, ensuring continuous operation.

Constructed with durable, food-grade materials—including stainless steel (304) for contact parts and wear-resistant rubber for peeling components—it avoids damaging walnut shells while ensuring hygiene. Equipped with adjustable rotation speed (50-150rpm) to adapt to husk moisture levels (fresh, slightly dried), it achieves high peeling efficiency with minimal walnut breakage. Compact or large-scale models are available, making it suitable for walnut farms, processing plants, and agricultural cooperatives.

Product Advantages

High Peeling Efficiency: Processes 300-3000kg/h (depending on model), 10-15 times faster than manual peeling, drastically reducing labor costs.

Low Shell Damage: Gentle friction from rubber/plastic blades ensures ≤3% walnut shell damage—critical for preserving walnut quality and market value.

Adjustable Adaptability: Variable rotation speed caters to different husk conditions (fresh, semi-dried), maintaining peeling effect across harvest stages.

Integrated Separation: Built-in husk-walnut separation system (airflow/conveyor) eliminates extra sorting steps, streamlining workflow.

Durable & Easy to Clean: Stainless steel contact parts resist corrosion; smooth surfaces and detachable peeling components simplify cleaning after use.

User-Friendly Operation: Simple control panel for speed adjustment; no professional training required—farm workers can master it quickly.

Application Scenarios

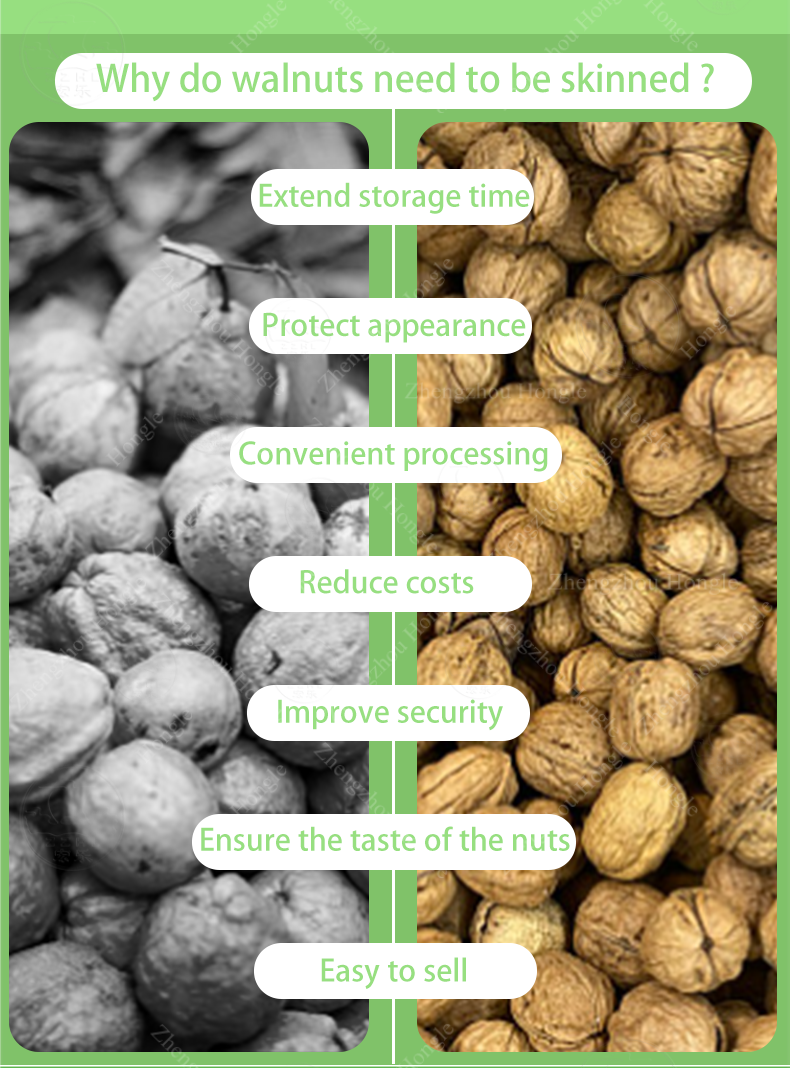

Walnut Farms: Processing freshly harvested walnuts to remove green husks immediately, preventing husk rot and shell staining (critical for fresh walnut quality).

Walnut Processing Plants: Integrating into pre-processing lines (before washing, drying, or shelling) to standardize walnut raw materials for subsequent production.

Agricultural Cooperatives: Centralized husk removal for member-grown walnuts, ensuring uniform quality for collective sales or further processing.

Fresh Walnut Markets: Peeling walnuts for direct retail, as peeled walnuts are more marketable and reduce customer prep work.

Organic Walnut Production: Physical mechanical peeling (no chemicals) maintains organic certification standards, avoiding husk-softening agents.

Technical Parameters

| Item | Value |

| Core Components | MOTOR |

| Place Of Origin | China |

| Brand Name | Hongle |

| Warranty | 1 Year |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Dimensions | 2200*1700*1300mm |

| Power | 380V |

| Voltage | 1.5kW |

| Output | 3.5t/h |

| Weight | 300kg |

| Material | SUS304 Stainless Steel |

Detailed Information