Apple Ginger Carrot Spiral Juicing for Juice Shops Digital Control Easy Mastery Fruit & Vegetable Juicer Machine

Apple Spinach Cucumber Spiral Juicing for Factories Low Noise ≤60dB Quiet Fruit & Vegetable Juicer Machine

- Overview

- Product Advantages

- Application Scenarios

- Product Parameters

- Product Details

- Recommended Products

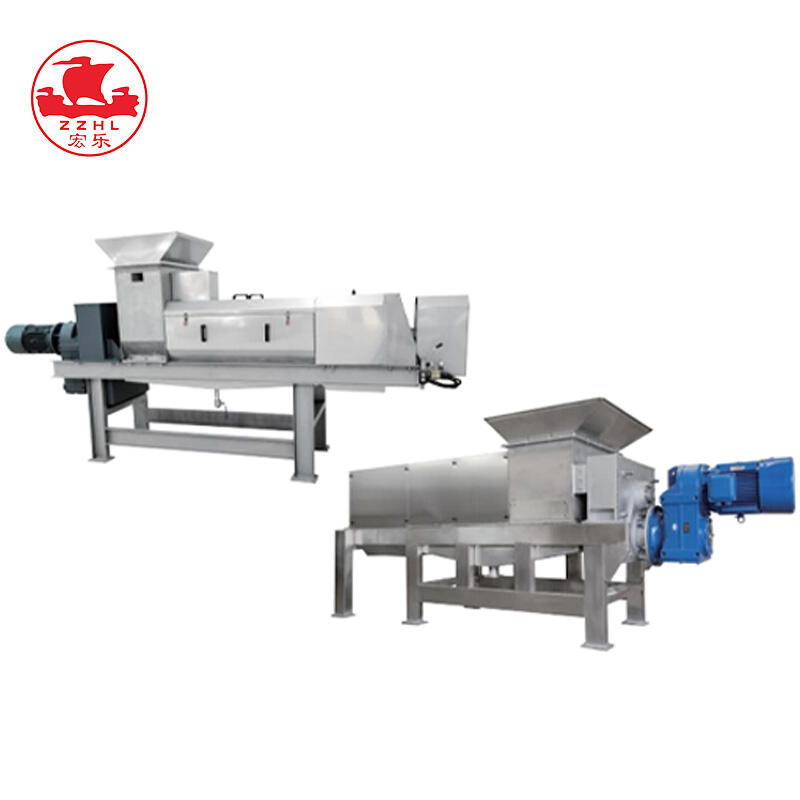

The Spiral Fruit & Vegetable Juicer Machine is a professional commercial juicing equipment designed for efficient extraction of fresh fruit and vegetable juice, featuring a unique spiral pressing structure. Made of food-grade 304 stainless steel, this Fruit & Vegetable Juicer Machine adopts low-speed spiral pressing technology (≤30rpm) to avoid nutrient loss caused by high-speed grinding—preserving 95%+ vitamins (e.g., vitamin C in citrus, antioxidants in berries) and natural flavors. It supports a wide range of produce, including soft fruits (strawberries, mangoes, grapes), hard vegetables (carrots, beets, celery), and leafy greens (spinach, kale), with a juice yield of 90%+ (20% higher than traditional centrifugal juicers) and pulp residue ≤5%. Equipped with user-friendly controls, it offers semi-auto/full-auto operation options, reducing 65% manual labor, and complies with FDA and CE international food safety certifications, making it ideal for juice shops, cafés, farms, and small-scale production facilities.

Product Advantages

Superior Juice Yield with Spiral Design: The spiral pressing structure of Fruit & Vegetable Juicer Machine ensures 90%+ juice extraction rate, 20% higher than traditional juicers, maximizing raw material utilization and reducing waste.

Nutrient & Flavor Preservation: Low-speed spiral operation (≤30rpm) avoids heat generation during juicing, retaining 95%+ natural vitamins, minerals, and fresh flavors—appealing to health-conscious consumers.

Food-Grade Safety & Durability: All food-contact parts (spiral press cavity, juice pipeline) are made of 304 stainless steel, featuring corrosion resistance, easy cleaning, and no heavy metal leaching, meeting FDA/CE standards.

Multi-Produce Adaptability: The adjustable spiral pressing pressure (0-40MPa) of Fruit & Vegetable Juicer Machine fits soft fruits, hard vegetables, and leafy greens—no need to replace parts, simplifying operation for various produce.

Low Residue & Smooth Juice: Precision spiral filtration system reduces pulp residue to ≤5%, eliminating the need for secondary filtering and ensuring smooth juice texture, suitable for direct consumption or bottling.

Easy Operation & Maintenance: Equipped with one-click start and digital control panel; modular spiral structure allows quick disassembly for cleaning; core components have a 3-year service life, lowering maintenance costs.

Application Scenarios

Juice Shops & Smoothie Bars: On-site fresh juicing with spiral pressing technology highlights "no additives, high nutrients"—a key selling point to attract health-focused customers (e.g., apple-carrot juice, spinach-kiwi juice).

Cafés & Restaurants: Complement meals with fresh spiral-pressed juice (e.g., orange-lemon juice for breakfast, beet-celery juice for salads) to enrich menu options and enhance customer experience.

Farms & Orchards: Process fresh harvests (e.g., berries, apples, carrots) into bottled juice via spiral juicer, increasing agricultural product added value and extending product shelf life.

Small-Scale Workshops & Startups: Low-investment entry into the fresh juice market; the compact spiral juicer supports small-batch production for local grocery stores, farmers’ markets, or e-commerce delivery.

Health Food Stores & Gym Cafés: Offer custom spiral-pressed juice blends (e.g., ginger-turmeric-carrot juice) to meet personalized nutrition needs of fitness enthusiasts and health-conscious shoppers.

Institutional Procurement: Schools, hospitals, and corporate cafeterias use spiral fruit & vegetable juicer machine to provide fresh, healthy juice daily—ensuring crowd nutrition while complying with food safety standards.

Product Parameters

| Without Hydraulic System | |||

| Model number | FR-180 | FR-260 | FR-350 |

| Output | 0.2-0.5t/h | 1t/h | 2t/h |

| Screw diameter | 180mm | 260mm | 350mm |

| Screw rotation speed | 5-15r/min | 5-15r/min | 5-15r/min |

| Hydraulic power | 0 | 0 | 0 |

| Motor power | 3-4KW | 5.5-7.5KW | 7.5-11KW |

| Dimensions | 1800*550*920 | 2200*700*1200 | 3380*900*1450 |

| Weight | 450KG | 900KG | 1300KG |

| Reducer | KAF77 | BWD3/KAF97 | FAF97 |

| Note | Depending on the different raw materials of the customers, the internal spiral structure is different and the rotational speed of the equipment is also different. | ||

| With Hydraulic System | |||||

| Model number | FR-420 | FR-500 | FR-550 | FR-20-630 | FR-870 |

| Output | 3-4t/h | 5-6t/h | 8-10t/h | 15-18t/h | 30-40t/h |

| Screw diameter | 420mm | 500mm | 550mm | 630mm | 870mm |

| Screw rotation speed | 5-15r/min | 5-15r/min | 5-15r/min | 5-15r/min | 5-15r/min |

| Hydraulic power | 1.1kw | 1.1kw | 1.5kw | 2.2kw | 3kw |

| Motor power | 11-15KW | 15-18.5KW | 22KW | 30kw | 45kw |

| Dimensions | 4280*1000*1750 | 5105*1200*2050 | 5220*1200*2150 | 5800*1300*2250 | 6800*1530*2475 |

| Weight | 2600KG | 3050KG | 3550KG | 4300kg | 7400kg |

| Reducer | FAF97 | FAF107 | FAF127 | FAF127 | FAF157 |

| Note | Depending on the different raw materials of the customers, the internal spiral structure is different and the rotational speed of the equipment is also different. | ||||

Product Details