- सारांश

- अनुशंसित उत्पाद

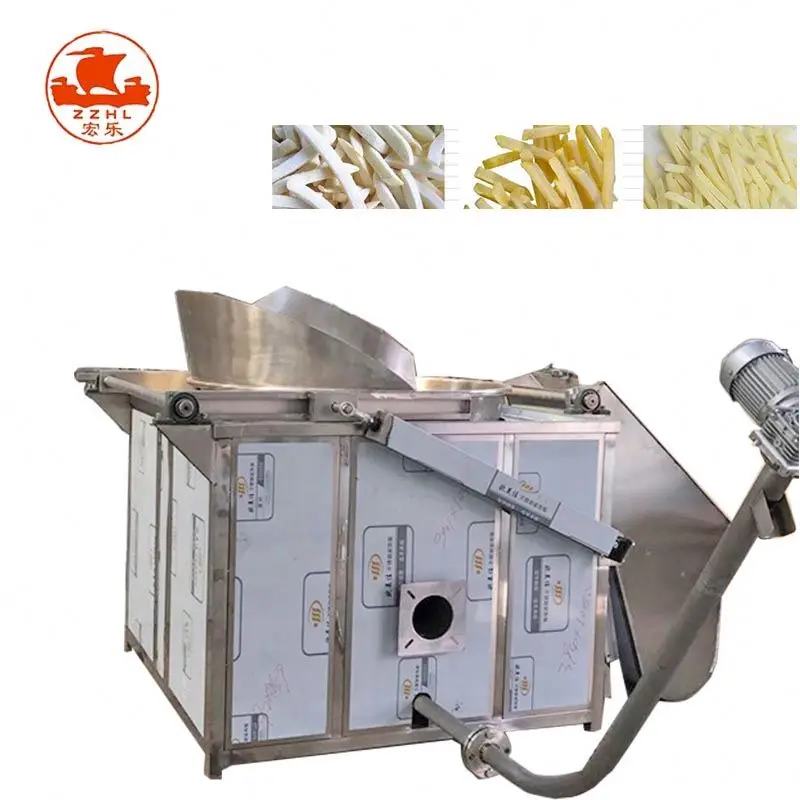

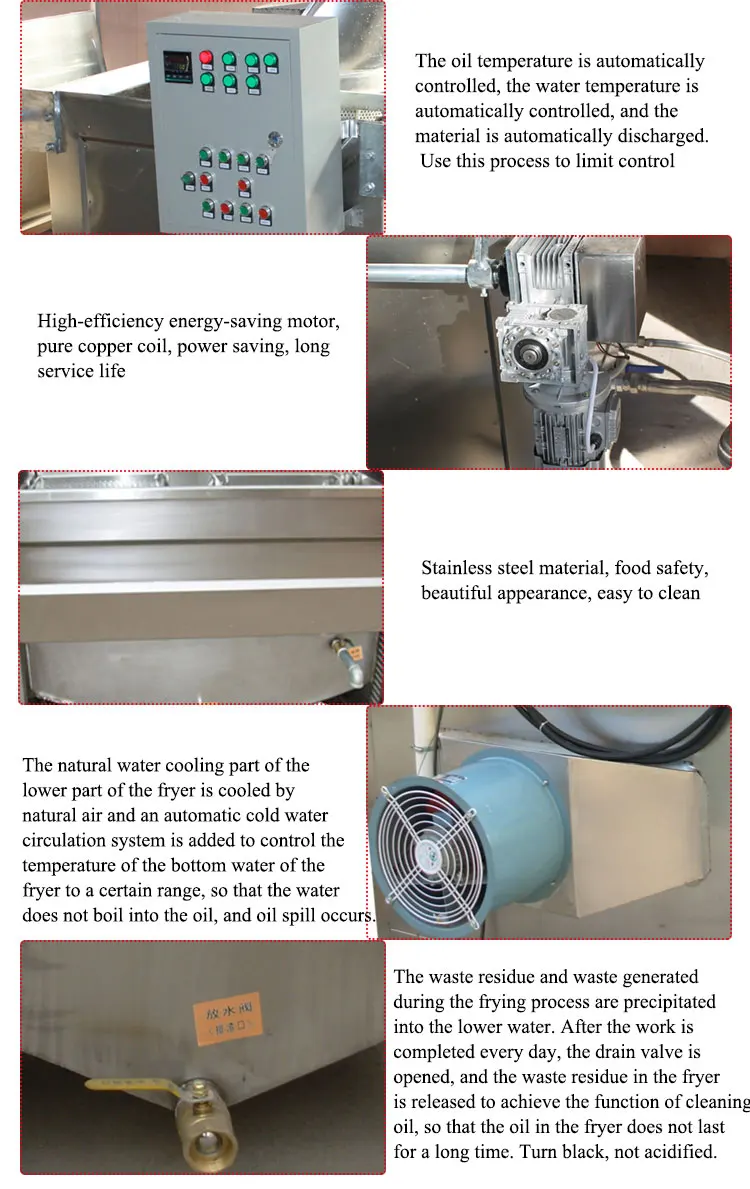

1. मिश्रण प्रणाली अधिक समग्र है: मुख्य और सहायक मिश्रण अक्ष बाएं कोण बीवेल गियरों द्वारा जुड़े होते हैं, प्रसारण स्थिर है, और गति विश्वसनीय है। यह भूनने की प्रक्रिया के दौरान उत्पाद के स्वभाविक गुणों से कारण बनने वाली उछल-फुटने की समस्या को प्रभावी रूप से हल कर सकता है।

3. ड्रेनेज सिस्टम अधिक आगे चला हुआ है: स्वतंत्र स्क्रेपिंग सिस्टम के साथ, जर्मन ड्रेनेज तकनीक से प्रेरित, परंपरागत तेल-पानी विभाजन फ्राइअर को बदलता है, पानी के बिना और पानी, नीचे की धूल को सीधे निकाल सकता है, परंपरागत तेल-पानी विभाजन विधि को पानी क्षेत्र में तेल फिल्म दीवार के पतन से बचाता है जो ऊपरी तले हुए क्षेत्र की तेल की गुणवत्ता को बदतर बना देता है।

मॉडल |

HLWD1000 |

HLWD1300 |

HLWD1500 |

माप |

1750*1500*1500 |

2100*1850*1600 |

2300*2100*1600 |

वजन |

450 |

620 |

830 |

वोल्टेज |

0.37KW बिजली से गर्मी 51KW |

0.37KW बिजली से गर्मी 63KW |

1.12kw बिजली से गर्मी 81KW |

क्षमता |

फूटी हुई खाद्यवस्तु (70-100KG/H) मूंगफली (200*350KG/H) |

फूटी हुई खाद्यवस्तु (100-150KG/H) मूंगफली (350*450KG/H) |

फूटी हुई खाद्यवस्तु (180-250KG/H) मूंगफली (450*600KG/H) |

तेल की मात्रा |

360L |

420L |

650ली |

तापमान विस्तार℃ |

0-400 |

0-400 |

0-400 |

पैकेज:

मानक निर्यात कार्टन पैकिंग.

डिलीवरी समय:

ऑर्डर की पुष्टि करने के बाद 3-20 दिन, विस्तृत डिलीवरी तारीख को उत्पादन सीज़न और ऑर्डर मात्रा के अनुसार तय किया जाना चाहिए।