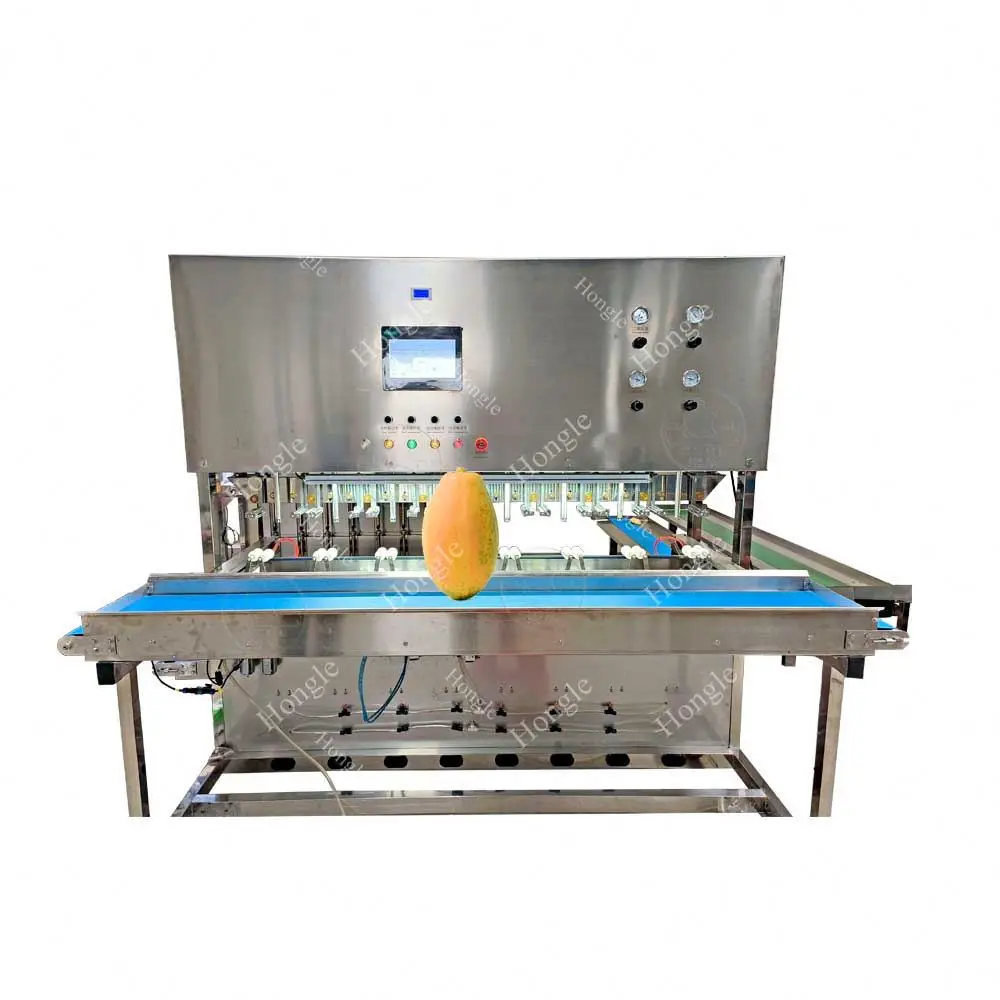

1. स्वचालित प्रक्रिया 1.1. खाद्य प्रणाली: कंपनशील प्लेटें या कनवेयर बेल्ट स्वचालित रूप से मंगो को प्रत्येक कार्य स्थल तक पहुँचाती हैं और उन्हें समान रूप से वितरित करती हैं। 1.2. स्थिति और ग्रेप्टिंग: रोबोटिक हाथ या ग्रेप्ट अच्छी तरह से मंगो को फिक्स करते हैं ताकि वे विभिन्न आकारों और आकारों को समायोजित कर सकें। 1.3. बुद्धिमान चालन: घूर्णन चाकूओं, लचीले कटिंग उपकरणों या उच्च-दबाव जल जेट प्रौद्योगिकी के माध्यम से, चाल दक्षतापूर्वक निकाली जाती है और गाठ को पूर्ण रूप से बनाये रखा जाता है। 1.4. दृश्य परीक्षण (वैकल्पिक): कैमरे या सेंसर चालन की गुणवत्ता का पता लगाते हैं, और अयोग्य उत्पाद स्वचालित रूप से हटा दिए जाते हैं। 1.5. डिसचार्ज श्रेणीबद्ध: चालित मंगो को स्वचालित रूप से अगली प्रक्रिया (जैसे मांस काटना, पैकेटिंग आदि) तक पहुँचाया जाता है। 2. मशीन की विशेषताएँ 2.1 पूरी तरह से बंद राखियों की डिग्री में हाइजीन मानकों के अनुरूप स्टेनलेस स्टील का शरीर, सफाई करने में आसान और सबजी के प्रति प्रतिरक्षी। 2.2 स्वचालित संचालन मानवीय संपर्क को कम करता है और प्रदूषण के जोखिम को कम करता है। 2.3 PLC + स्पर्श पर्दे नियंत्रण प्रणाली, चादर की मोटाई और गति जैसे पैरामीटर सेट कर सकते हैं। 2.4 दोष स्व-विकृति कार्य के उपकरण की स्थिर संचालन को सुनिश्चित करता है।

पूरी तरह से स्वचालित 8-स्टेशन आम की छाल काटने वाली मशीन मॉड्यूलर डिजाइन और बुद्धिमान नियंत्रण प्रौद्योगिकी के माध्यम से आम की छाल काटने की प्रक्रिया को दक्ष, सटीक और स्वच्छ उत्पादन करती है, जो विशेष रूप से ऑटोमेशन अपग्रेड की ओर बढ़ने वाली भोजन प्रसंस्करण कंपनियों के लिए उपयुक्त है। यदि अधिक रूपांतरण की आवश्यकता है (जैसे कि पिटिंग कार्य जोड़ना या विशेष फलों के आकार को समायोजित करना), आप हमसे डिजाइन योजना समायोजित करने के लिए बातचीत कर सकते हैं।