High-Capacity Oil Extraction Tank | Commercial Essential Oil Distiller, Plant-Based Oil Production

Steam Distillation Essential Oil Extraction Tank | Herbal & Flower Oil Extractor, 304 Stainless Steel

- Overview

- Product Advantages

- Application Scenarios

- Technical Parameters

- Detailed Information

- Recommended Products

High-Capacity Oil Extraction Tank | Commercial Essential Oil Distiller, Plant-Based Oil Production

Product Overview

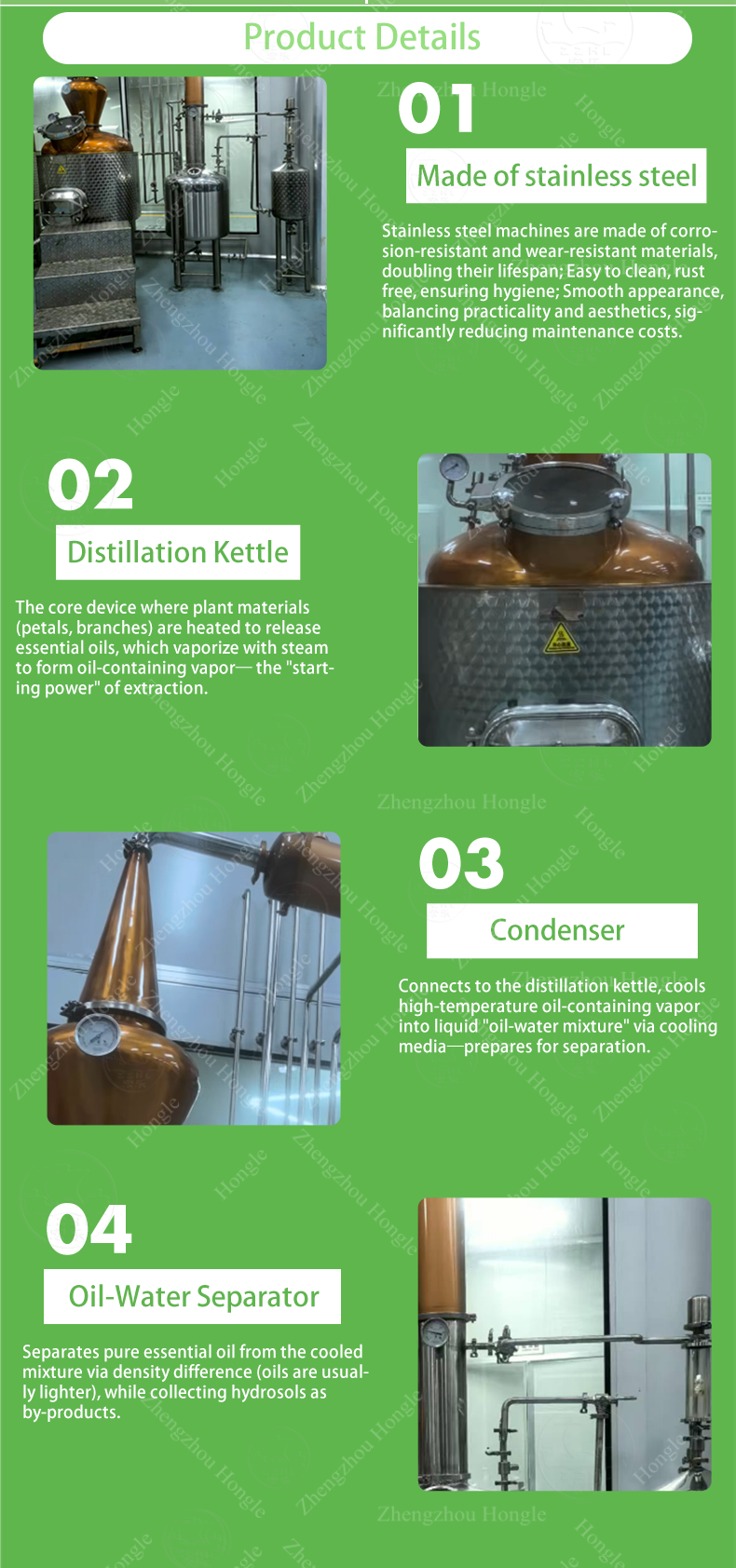

The Essential Oil Extraction Tank is a specialized device designed to extract pure essential oils from plants, herbs, and flowers using steam distillation—an eco-friendly method that preserves the natural aroma and properties of oils. Its structure includes a 304 stainless steel distillation chamber, heating system, and condensation unit: hot steam gently penetrates plant materials to release oils, which then condense into a liquid mixture. The oil naturally separates from water due to density differences, ensuring a clean, solvent-free result. All contact parts are food-grade, preventing contamination, and the detachable design makes cleaning and maintenance simple.

Product Advantages

Pure, Natural Oils: Solvent-free steam distillation ensures oils retain their natural properties, free from chemical residues—ideal for aromatherapy and cosmetics.

Enhanced Yield: Optimized steam flow and temperature control increase oil output by 20-30% compared to basic extractors, reducing raw material waste.

Botanical Flexibility: Customizable settings handle diverse plants: low heat for fragile flowers, higher temperatures for woody herbs or citrus peels.

Durable & Safe: 304 stainless steel resists corrosion from plant acids; built-in overpressure protection and insulation ensure safe operation.

Cost-Effective: Energy-saving heating cuts power usage by 15%; easy-to-maintain parts reduce downtime and operational costs.

Application Scenarios

Aromatherapy Products: Extracting lavender, tea tree, and eucalyptus oils for diffusers, massage oils, and scented candles.

Natural Cosmetics: Producing rose, sandalwood, and citrus oils for organic skincare (creams, serums) and natural perfumes.

Herbal Wellness: Creating essential oils for holistic uses, such as peppermint oil for energy or chamomile oil for relaxation.

Food & Beverages: Extracting pure mint, lemon, or orange oils as natural flavor additives for drinks, desserts, and snacks.

Agricultural Value Addition: Processing aromatic crops (lavender, rosemary farms) into high-value essential oils for commercial sale.

Technical Parameters

| Specification | DTQ-0.5 | DTQ-1 | DTQ-2 | DTQ-3 | DTQ-4 | DTQ-6 | DTQ-8 | DTQ-10 |

| Volume (L) | 600 | 1200 | 2300 | 3200 | 4300 | 6300 | 8500 | 11000 |

| Design pressure inside the equipment(Mpa) | 0.09 | |||||||

| Jacket design pressure(Mpa) | 0.3 | |||||||

| Feeding port diameter(mm) | 400 | 400 | 400 | 400 | 500 | 500 | 500 | 500 |

| Heating area(㎡) | 2.4 | 3 | 4.7 | 6.8 | 8 | 10 | 12 | 12 |

| Condensation area(㎡) | 3 | 4 | 5.4 | 8 | 10 | 10 | 15 | 18 |

| Cooling area(㎡) | 0.5 | 0.5 | 1 | 1 | 1 | 2.2 | 2.2 | 3 |

| Filtration area(㎡) | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.3 | 0.3 | 0.3 |

| Diameter of the slag discharge door(mm) | 600 | 800 | 800 | 1000 | 1200 | 1400 | 1400 | 1400 |

| Steam consumption(kg/h) | 285 | 285 | 346 | 570 | 660 | 718 | 903 | 1140 |

| Water consumption(T/h) | 2.1 | 2.1 | 2.5 | 4.2 | 4.5 | 5.5 | 6.7 | 6.7 |

| Heating steam pipe opening(mm) | 32 | 32 | 32 | 40 | 40 | 50 | 50 | 50 |

| Exhaust pipe opening(mm) | 100 | 100 | 100 | 125 | 125 | 150 | 150 | 150 |

| Cooling water pipe opening(mm) | 40 | 40 | 40 | 50 | 50 | 50 | 65 | 70 |

Detailed Information