Introduction:

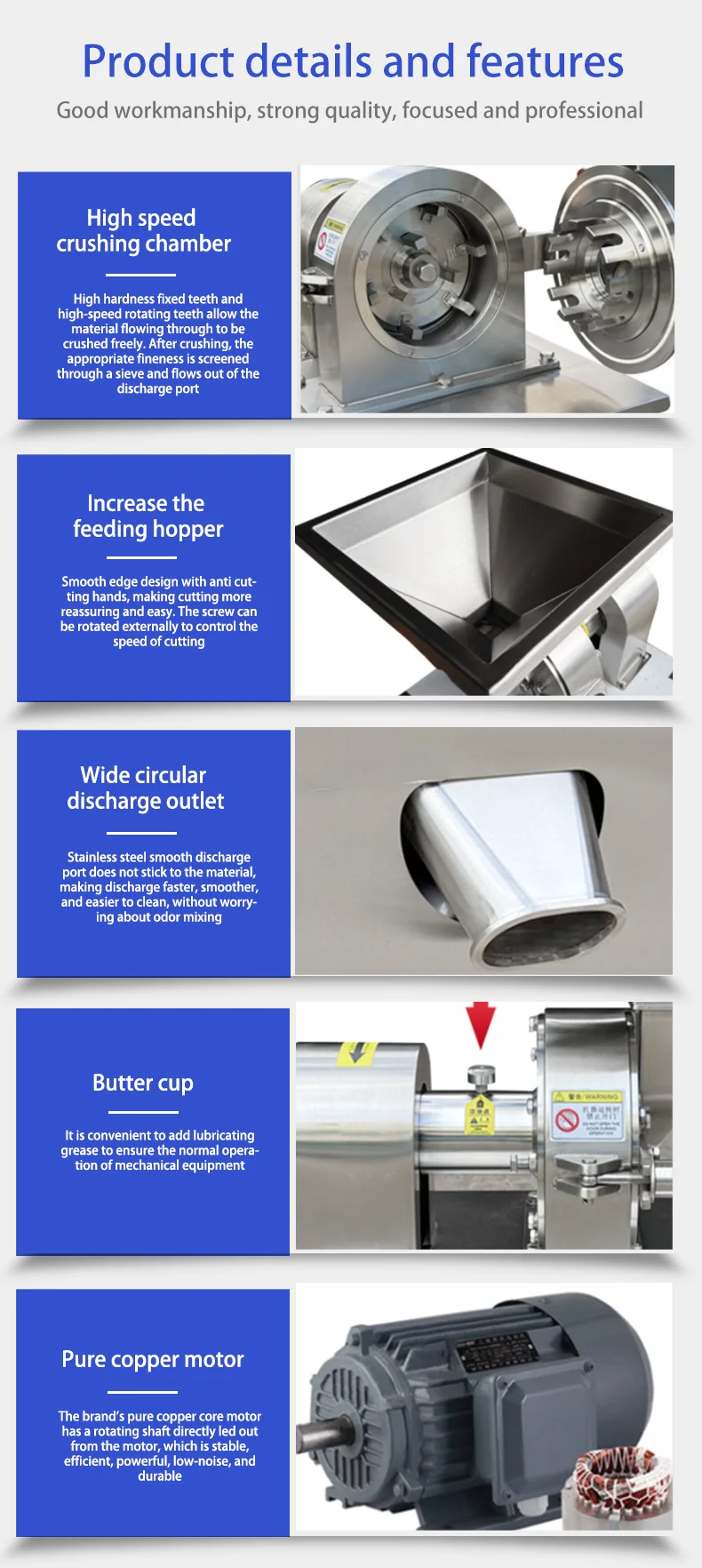

This water-cooled crusher is engineered for high-capacity processing of diverse materials, with a production range of 10-1000kg/h and adjustable fineness from 10 to 200 mesh—perfect for scenarios requiring moderate to coarse particle sizes. Its core feature is the integrated water cooling system, which controls temperature rise during grinding, making it suitable for heat-sensitive materials (e.g., oily seeds, volatile spices) and preventing overheating-induced quality degradation. Made of 304 stainless steel, it meets food-grade and industrial standards, with CE certification for global use. Whether handling dry hard materials (grains, minerals) or wet pastes (fruit purees), this machine balances efficiency and material protection.

Key Advantages

Water Cooling System: Stable Temperature ControlA circulating water jacket wraps the grinding chamber, limiting temperature rise to ≤50℃ during operation. This is critical for materials sensitive to heat—for example, preserving the oil content in sesame seeds (which oxidizes at high temperatures) or maintaining the aroma of star anise.

The closed-loop cooling system (water + optional antifreeze) operates continuously, supporting 24-hour non-stop production without frequent water refills.High Capacity & Adjustable Fineness (10-200 Mesh)Capacity flexibility: From small-batch workshops (10kg/h) to large factories (1000kg/h), with customizable models for specific output needs.

Fineness control: 10-200 mesh adjustment via a precision gap regulator, suitable for various applications:

10-30 mesh: Coarse grinding (e.g., crushed red pepper for hot pot seasonings, cracked grains for porridge).

40-80 mesh: Medium grinding (e.g., wheat flour for noodles, herbal chunks for decoctions).

100-200 mesh: Fine grinding (e.g., spice powder for sausage fillings, rice flour for baby food).

Uniform particle size: Built-in screening ensures 95% of output meets target fineness, reducing rework.Durable & Safe ConstructionAll material-contact parts are 304 stainless steel (optional 316 for corrosive materials), resisting rust and wear, and easy to clean.

Overload & overheat protection: Automatically shuts down if foreign objects (e.g., stones) enter or temperature exceeds 60℃, protecting the motor and extending service life.

Low dust design: Equipped with a cyclone separator and dust cover, keeping the workshop clean and material recovery rate ≥97%.Multi-Material & Wet/Dry CompatibilityDry grinding: Handles hard/soft materials—grains (corn, barley), spices (cumin, cinnamon), herbs (astragalus, licorice), and minerals (gypsum, limestone).

Wet grinding: Suitable for materials with moisture content ≥20%, such as fruit pulps (apple, banana), vegetable pastes (carrot, pumpkin), and oily materials (peanut, almond).

Application Scenarios

Food Industry: Crush grains into coarse flour (for bread, biscuits), grind spices into medium particles (for seasoning packets), or process fruits into puree powder (for baby food).

Agriculture: Turn crop by-products (corn cobs, soybean straw) into animal feed additives (10-30 mesh for cattle feed).

Pharmaceuticals: Grind herbal medicines into 40-80 mesh chunks for decoctions or loose teas, preserving active ingredients.

Chemical Industry: Process non-toxic fillers (talc, kaolin) into 50-100 mesh powders for paints and ceramics.

Cosmetics: Crush natural ingredients (oatmeal, lavender) into 80-150 mesh for body scrubs.