- Overview

- Recommended Products

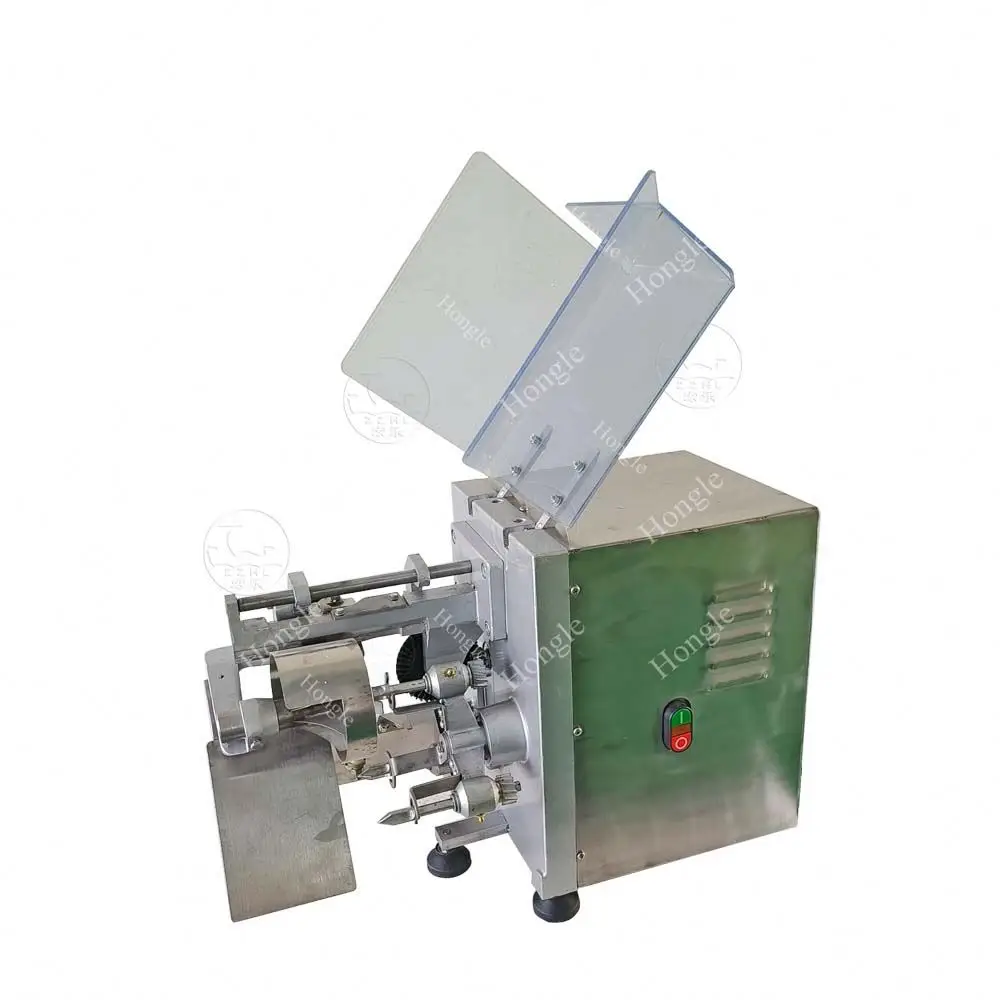

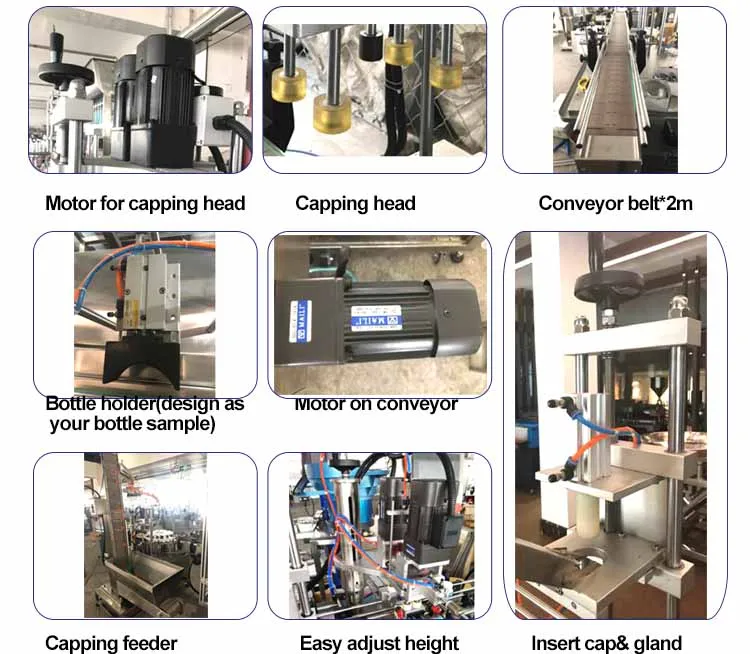

1. Auto- Linear Capping Machine(screw type)

1.1 Principle and characteristics:

Automatic capping machine is mainly suitable for different material specifications and different specifications of the cover,

spin (rolling) cover. Suitable for screw cover, anti theft cover, child proof cover, press in cover, etc.. Preparation of

constant torque capping head, the pressure can be easily adjusted. Compact and reasonable structure, can be easily linked

with other equipment into line, dust-proof cover can be purchased.

1.2 Functions:

Applicable to all kinds of cosmetics, medicine, veterinary drugs, pesticides, lubricating oil industry capping machine equipment.

1.3Machine advantages:

1.3.1 Straight line design, composed of convenient and beautiful lines.

1.3.2. Host speed using imported inverter, stepless speed regulation.

1.3. 3. The strong electromagnetic left-hand cover torque converter, completely solve the traditional mechanical friction plate in the rotary cover spurts ills.

This machine can be designed according to the special requirements of customers.

Linear duckbill Capping machine suitable for different size of caps and bottles, screw power and rotation speed of screw capping machine is adjustable.

It is widely apply to pharmaceutical, chemical, food, beverage, grease and pesticide industry.

2.2 Features:

2.2.1.With features like ease of operation, highly productive and competitive price etc.

2.2.2.This machine can be operated alone or coupled with filling machine, make the formation of filling line possible.

Parameters :

Voltage |

AC220V /110v 50-60hz |

Power |

356W |

Production speed |

20-25pcs/min |

Air pressure |

0.6-0.8mpa |

required air compressor |

3kw 100L |

Bottle diameter |

35-110mm H:150-300mm |

Machine weight |

268kg |

Machine size |

2000*1400*1400mm |

Name |

Auto- Linear Capping Machine |

Name |

Rotary capping machine |

Voltage |

220V 50-60HZ |

USing Gas Source |

0.6-0.8Mpa |

Capping Range |

Diameter ≤50mm |

Machine size |

2000*1500*1600mm (depends on bottle size) |

Lock Bottle Range |

H:50-320mm W:20-100m |

Net Weight |

312KG |

Capping Rate |

25-35Pcs/Min |

Required air compressor |

≥3kw 100L |

Power |

365w-1.5kw |

Voltage |

AC220V, 50/60HZ |

Air source |

0.4-0.6Mpa |

Bottle diameter |

32-80mm |

Bottle height |

32-300mm |

Capping speed |

30-45pce/min |

Capping torque |

4-8kg/cm |

Required air compressor |

≥1.5kw 65L |

Voltage |

AC 220V/110V 50-60Hz |

Power |

40W |

Cap diameter |

10-50mm |

Bottle height |

40-200mm |

Capping speed |

30-45Pcs/Min |

Machine size |

430*404*580mm |

Machine weight |

20kgs |

Pneumatic Handhold Capper

HL-MPXG200

|

|

1.Voltage :AC220V 50/60HZ 2.Power: 80W

3.Cap Diameter : 10-50mm

4.Speed : 30-90 bottles/min

5.Machine Size :70*70*300mm

6.Machine Weight:1 kg

|

1.Voltage :AC220V 50/60HZ 2.Power: 80W 3.Cap Diameter : 10-50mm

4.Speed : 30-90 bottles/min 5.Machine Size :70*70*300mm 6.Machine Weight:1 kg

|