What Is a CE Certified Aerosol Filling Machine and Why It Matters

Understanding CE Certification in the Context of Aerosol Manufacturing

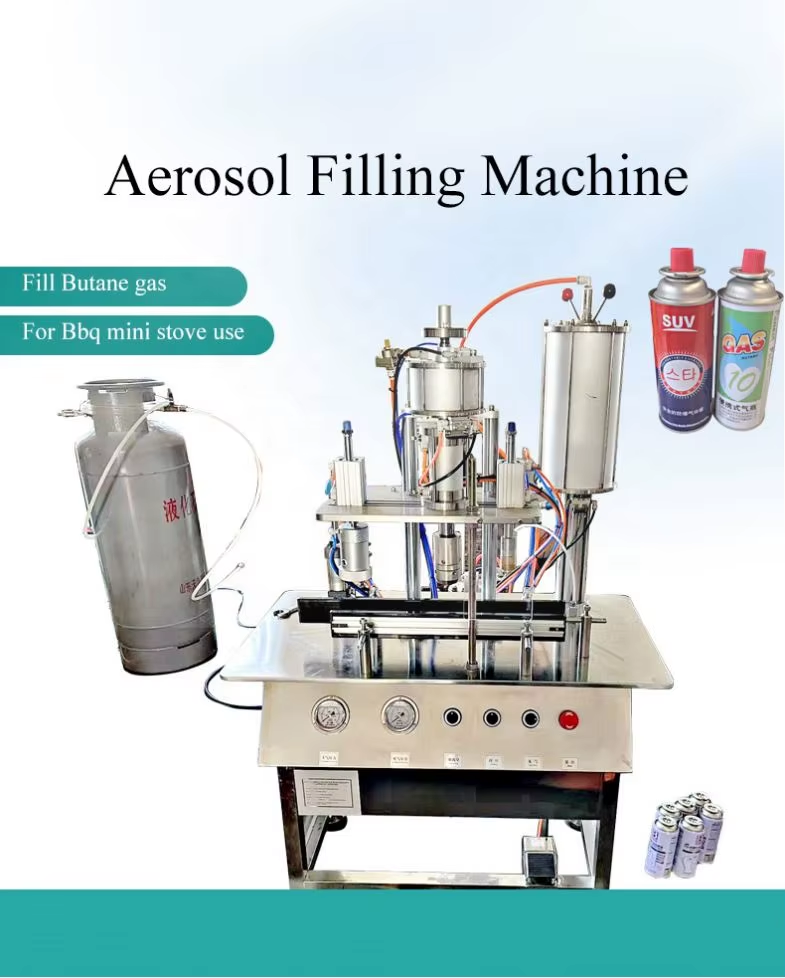

When an aerosol filling machine carries CE certification, it basically means it ticks all the boxes for EU safety regulations set out in the Machinery Directive 2006/42/EC. The certification process checks whether the machine's design actually stops dangerous situations from happening, like pressure leaks or workers getting exposed to chemicals. This becomes really important stuff when dealing with flammable gases such as butane or propane in production lines. Third party organizations including TÜV Rheinland conduct these inspections, looking specifically at how well the equipment handles static electricity buildup and maintains structural strength under pressure. Getting this CE mark isn't just good practice either it's legally required if companies want to sell their machines across all 31 countries in the European Economic Area. Without proper certification, products simply can't enter these markets.

Integration with Automated Production Lines for End-to-End Efficiency

Today's CE certified fillers work really well alongside robotic can handling systems and those PLC controlled packaging lines, cutting down on changeover time by around two thirds. A manufacturer making automotive paints saw their production jump nearly a quarter when they connected one of these certified fillers to some smart conveyor belts that talk to each other through the internet (check out the 2023 report on automation returns). The digital records keep tabs on all sorts of important stuff like how accurate the propellant measurements are (within half a percent) and whether those seals hold up properly. This kind of detailed tracking makes it much easier to prepare for audits and maintain proper documentation as required by ISO 9001 quality standards.

Safety and Regulatory Advantages of CE Certified Aerosol Equipment

Compliance with EU Machinery Directive and International Standards

Machines with CE certification actually follow the EU Machinery Directive from 2006 (number 2006/42/EC), which helps companies stay compliant across all those 31 countries in the EEA plus meets international standards such as IECEx when dealing with potentially explosive settings. According to some market analysis published last year on solenoid valves, factories that switch to CE marked gear tend to cut down their chances of running afoul of regulations by around three quarters. Plus these setups are built to satisfy the ATEX rules too (Directive 2014/34/EU), something absolutely necessary if handling flammable materials properly is part of daily operations at any facility working with volatile substances.

Explosion-Proof Design for Safe Handling of Flammable Materials

Explosion proof enclosures work by keeping electrical parts separate from those flammable vapors that can cause trouble, so there's basically nothing to ignite even when something goes wrong inside. These safety systems are built according to the strict requirements for Zone 1 and 21 hazardous environments as outlined by both ATEX and IECEx regulations. Industry reports suggest they cut down on explosion dangers by around 89 percent in places where explosions are a major concern. The enclosures come equipped with pressure relief valves plus gas detectors that monitor the air continuously, making sure dangerous vapor levels never reach half of what's considered explosive according to safety standards.

Future Trends: Smart Technology and Sustainability in Aerosol Filling

IoT Integration and Remote Monitoring for Predictive Maintenance

IoT sensors in modern CE-certified machines monitor pressure, valve condition, and fill accuracy in real time. Using predictive maintenance algorithms, these systems reduce unplanned downtime by 40% compared to reactive approaches (2024 industrial automation studies). PLCs analyze vibration and thermal data to schedule repairs proactively, supporting continuous 24/7 operations.

Energy-Efficient Designs and Sustainable Manufacturing Practices

The best machines on the market now come equipped with energy recovery systems that can capture around two thirds of the heat wasted by compressors and put it back into controlling propellant temperatures. Manufacturers are also turning to biodegradable lubricants these days, along with filters that can be recycled rather than thrown away. Plus there's this modular design approach which means companies don't have to replace entire systems when they want to go green. All these improvements fit right in with what's happening across the industry regarding sustainability. Take film blowing technology for instance where we're seeing real gains in how efficiently polymers are used throughout production processes.

FAQ

What is the importance of CE certification for aerosol filling machines?

CE certification ensures that aerosol filling machines meet the EU safety regulations, reducing risks related to pressure leaks, chemical exposure, explosions, and more. It is essential for selling products in the European Economic Area.

How does CE certification enhance workplace safety?

CE-certified machines incorporate built-in protections such as automatic shut-offs and anti-static parts, which significantly decrease workplace accidents and ensure compliance with safety standards.

How do CE-certified machines integrate with automated production lines?

CE-certified fillers can efficiently work with robotic can handling systems and PLC-controlled packaging lines, improving production efficiency and ensuring compliance with ISO quality standards.

How does explosion-proof design contribute to safety?

Explosion-proof designs prevent electrical parts from igniting flammable vapors, drastically reducing explosion risks in hazardous environments, and adhere to ATEX and IECEx regulations.

What future trends are shaping aerosol filling machines?

Trends include IoT integration for predictive maintenance, energy-efficient designs, and modular systems to support sustainability efforts.

Table of Contents

- What Is a CE Certified Aerosol Filling Machine and Why It Matters

- Safety and Regulatory Advantages of CE Certified Aerosol Equipment

- Future Trends: Smart Technology and Sustainability in Aerosol Filling

-

FAQ

- What is the importance of CE certification for aerosol filling machines?

- How does CE certification enhance workplace safety?

- How do CE-certified machines integrate with automated production lines?

- How does explosion-proof design contribute to safety?

- What future trends are shaping aerosol filling machines?