- Overview

- Recommended Products

Commercial Peanut Butter Roasting Making Grinding Processing Machine sesame tahini production line

Product Description

Introduction of Working process

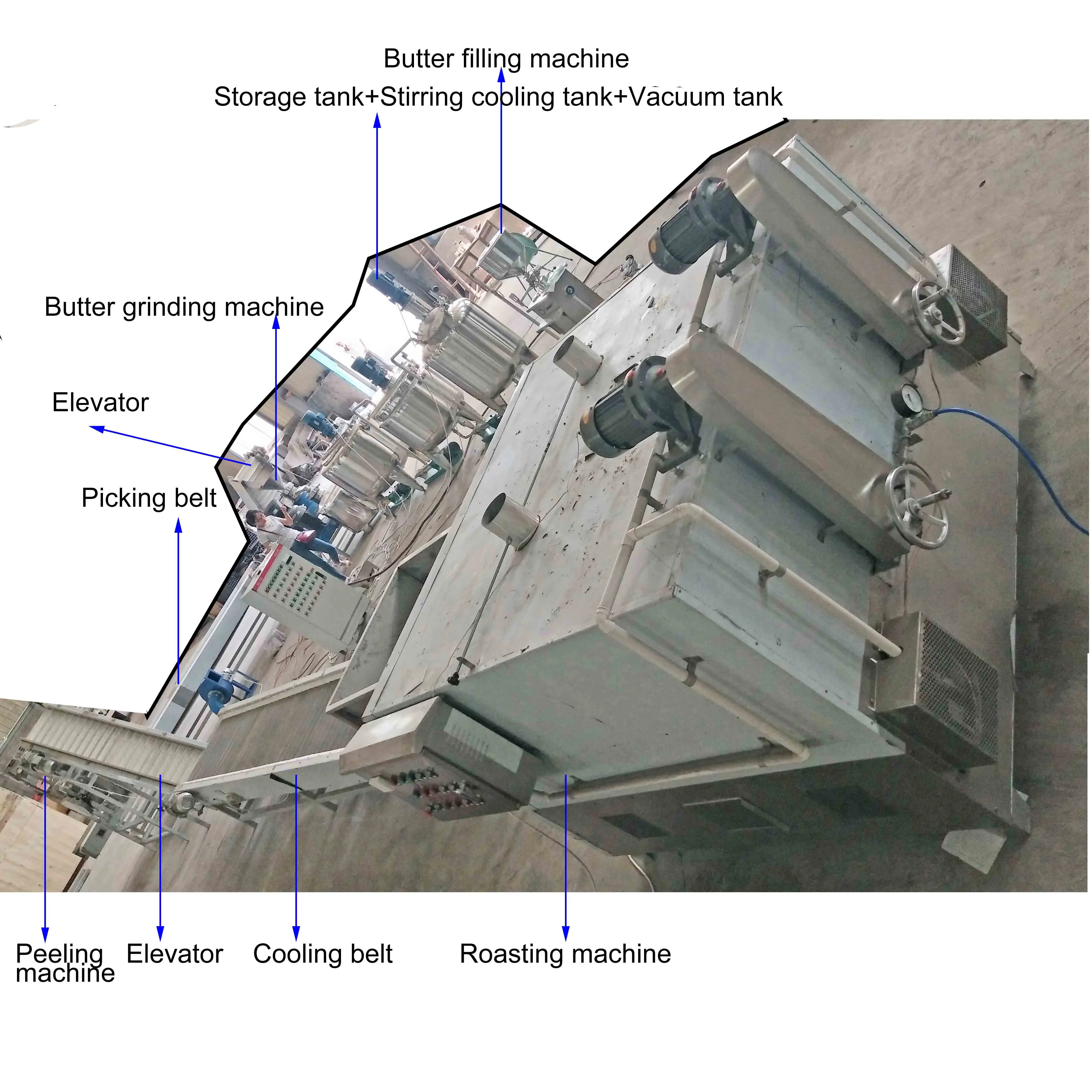

Roasting machine--hopper belt--cooling belt--peeling machine---conveyor belt--lift--peanut butter machine--stock tank--vacumm

tank---stock tank

Main equipments of this line are peanut/sesame/cashew/almond roaster, peeling machine, picking belt, elevator, peanut butter grinding machine, agitator tank, transfer pump, mixer, homogenizer, fine grinding machine, vacuum tank, cooling machine, filling

machine and so on.

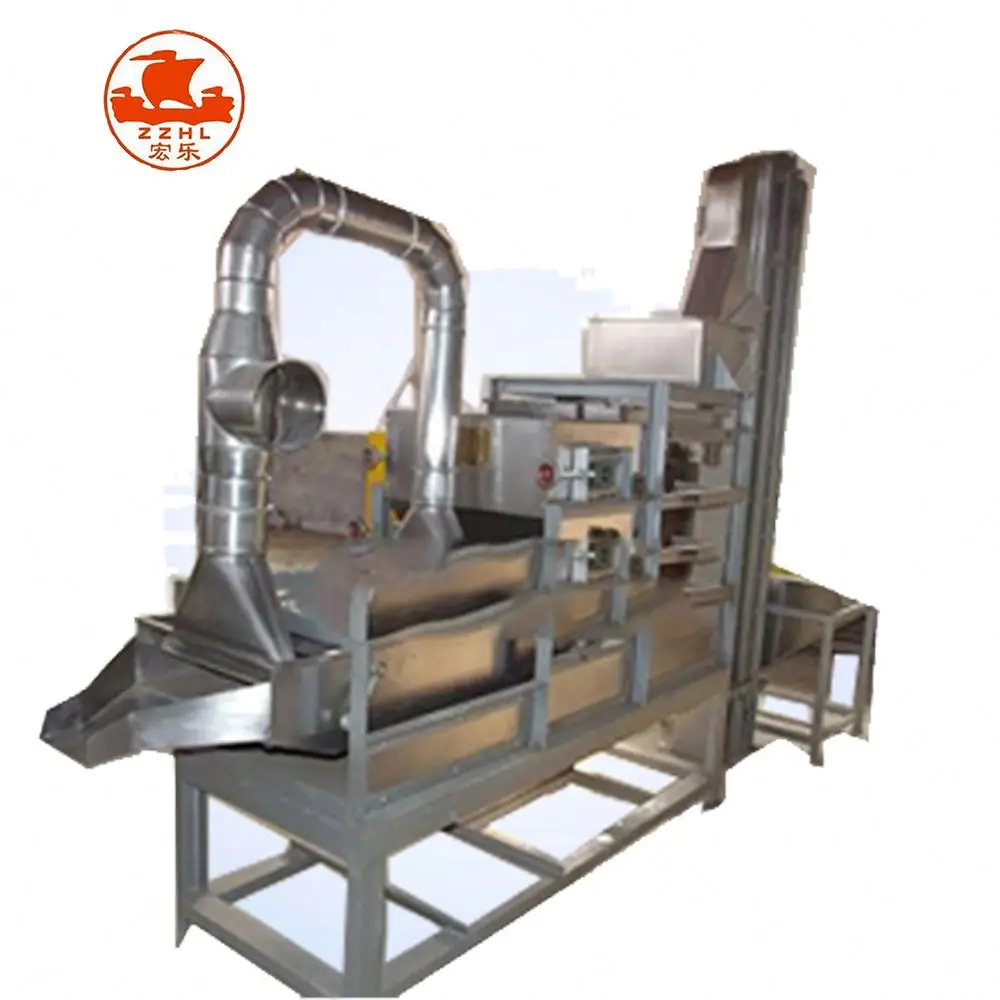

1. Roasting: Batch roaster’s working temperature is 200-210 ºC, 20-30 minutes. Use batch roaster will bake some delicious smells.

2. Cooling: Peanut will be send cooling belt to cool.

3. Peeling: Put the roasted peanuts into peeler to take off the red skin, the double rollers will frication red skin, the simple cyclone system will suck the red skins, most of them will be put in half-piece, then fall to the selecting conveyor, the over-roasted and un-blanched peanut kernel is picked up by manual or mechanical. (It is matched with manual type conveyor in

the quotation)

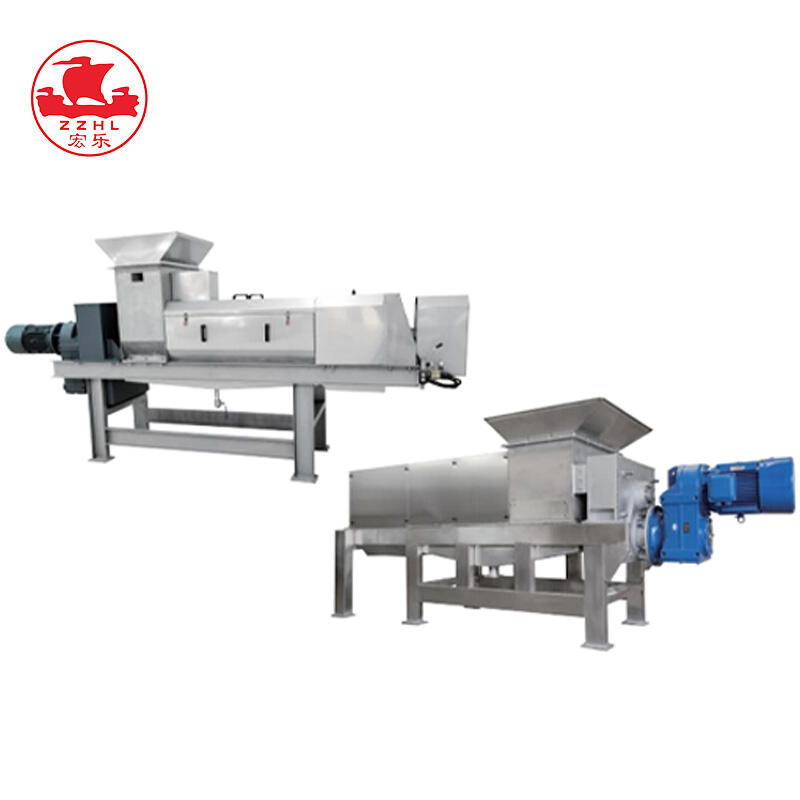

4.Primary grinding: Using steel grinder to make the first grinding.

5.Second grinding: Using colloid grinder to make the second grinding, the fineness of grinding is controlled below 7μm,temperature of grinding is controlled below 68C.

6. Cooling Mixing: make the butter more homogeneous and the butter through second grinding should be cooled immediately. The temperature should go down 45C.

7. Buffer Tank: Short time storage and take out the air from peanut butter

8. Storage tank: settling down in the storage tank till the temperature drop to air temperature.

9. Filling machine: Automatic filling machine, the finished peanut butter is packed into 200g/500g/1000g bottle.

This peanut butter making machine line can produce stable peanut butter, particle peanut butter and common type of peanut butter.Also produce a stable and common type of sesame tahini.

Please tell me what capacity do you need ?then we recommend suitable machine to you.

Introduction of Working process

Roasting machine--hopper belt--cooling belt--peeling machine---conveyor belt--lift--peanut butter machine--stock tank--vacumm

tank---stock tank

Main equipments of this line are peanut/sesame/cashew/almond roaster, peeling machine, picking belt, elevator, peanut butter grinding machine, agitator tank, transfer pump, mixer, homogenizer, fine grinding machine, vacuum tank, cooling machine, filling

machine and so on.

machine and so on.

1. Roasting: Batch roaster’s working temperature is 200-210 ºC, 20-30 minutes. Use batch roaster will bake some delicious smells.

2. Cooling: Peanut will be send cooling belt to cool.

3. Peeling: Put the roasted peanuts into peeler to take off the red skin, the double rollers will frication red skin, the simple cyclone system will suck the red skins, most of them will be put in half-piece, then fall to the selecting conveyor, the over-roasted and un-blanched peanut kernel is picked up by manual or mechanical. (It is matched with manual type conveyor in

the quotation)

4.Primary grinding: Using steel grinder to make the first grinding.

5.Second grinding: Using colloid grinder to make the second grinding, the fineness of grinding is controlled below 7μm,temperature of grinding is controlled below 68C.

6. Cooling Mixing: make the butter more homogeneous and the butter through second grinding should be cooled immediately. The temperature should go down 45C.

7. Buffer Tank: Short time storage and take out the air from peanut butter

8. Storage tank: settling down in the storage tank till the temperature drop to air temperature.

9. Filling machine: Automatic filling machine, the finished peanut butter is packed into 200g/500g/1000g bottle.

2. Cooling: Peanut will be send cooling belt to cool.

3. Peeling: Put the roasted peanuts into peeler to take off the red skin, the double rollers will frication red skin, the simple cyclone system will suck the red skins, most of them will be put in half-piece, then fall to the selecting conveyor, the over-roasted and un-blanched peanut kernel is picked up by manual or mechanical. (It is matched with manual type conveyor in

the quotation)

4.Primary grinding: Using steel grinder to make the first grinding.

5.Second grinding: Using colloid grinder to make the second grinding, the fineness of grinding is controlled below 7μm,temperature of grinding is controlled below 68C.

6. Cooling Mixing: make the butter more homogeneous and the butter through second grinding should be cooled immediately. The temperature should go down 45C.

7. Buffer Tank: Short time storage and take out the air from peanut butter

8. Storage tank: settling down in the storage tank till the temperature drop to air temperature.

9. Filling machine: Automatic filling machine, the finished peanut butter is packed into 200g/500g/1000g bottle.

This peanut butter making machine line can produce stable peanut butter, particle peanut butter and common type of peanut butter.Also produce a stable and common type of sesame tahini.

Please tell me what capacity do you need ?then we recommend suitable machine to you.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Related Products

*If you can not open the links above on Alibaba APP on mobile phone, please use IE browser to visit our website:

https://chinafoodmachine.en.alibaba.com.

https://chinafoodmachine.en.alibaba.com.

Packing & Delivery

Our Company

Certifications

FAQ

Contact Me

Need more machine details or video ? Please contact us directly