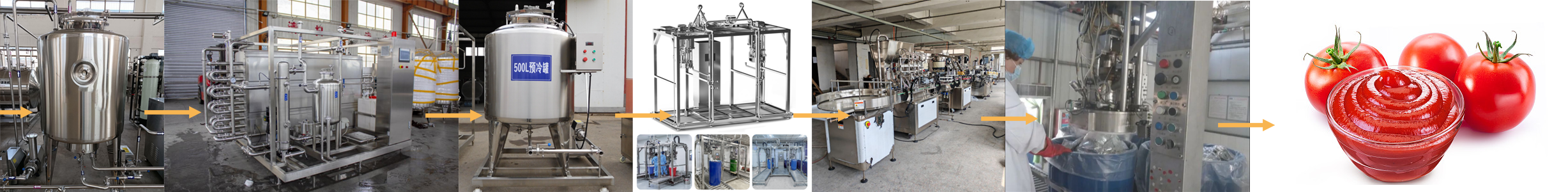

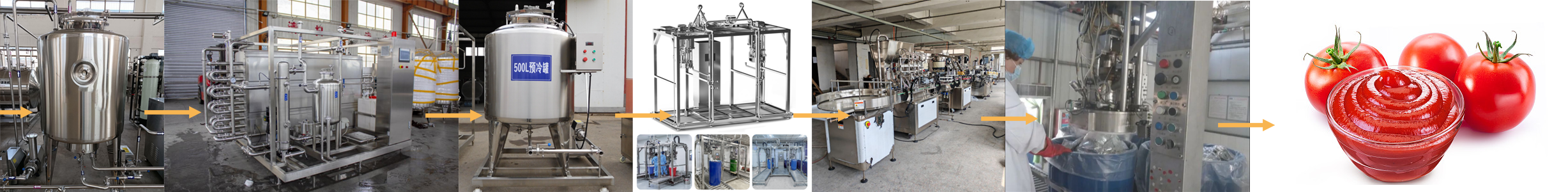

Ketchup, a staple condiment adored across the globe, enriches the taste of countless dishes while offering notable nutritional benefits. Its production is a complex, multi - stage process that demands precision at every turn, from the careful sourcing of raw materials to the meticulous packaging of the final product. Below, we explore the detailed operations of a ketchup production line, uncovering the journey of fresh tomatoes as they transform into the beloved condiment.

Ripe tomatoes serve as the cornerstone of ketchup production. To ensure top - tier quality, only tomatoes that are fresh, free from any signs of pests or diseases, and at the ideal stage of ripeness are selected. A stringent selection and cleaning process is implemented to rid the tomatoes of surface contaminants and potential pesticide residues.

-

Selective Sorting: Tomatoes are carefully chosen based on specific criteria. Fully matured specimens with a vivid color, high dry matter content, thin skins, thick flesh, and minimal seeds are preferred. This selection process, which can be carried out manually or with the aid of

machinery, effectively weeds out subpar tomatoes, such as those that are overripe or damaged, guaranteeing the freshness and quality of the raw material.

-

Thorough Cleaning: Specialized cleaning equipment, like bubble washers, is employed to rinse the tomatoes multiple times with clean water. This repeated rinsing process effectively removes dirt, soil, and any lingering pesticide residues, ensuring the tomatoes are pristine and ready for further processing.

Once cleaned, peeled, and seeded, the tomatoes proceed to the grinding phase, where they are transformed into a pulp. The goal of pulping is to blend the tomato pulp and juice thoroughly, setting the stage for subsequent processing. The resulting pulp is then concentrated by removing excess water through evaporation.

-

Initial Crushing: A tomato crusher is used to break down the tomatoes into smaller pieces. This fragmentation facilitates the separation of the pulp from the juice, enhancing the overall pulping efficiency.

-

Pre - heating Treatment: The crushed tomato pieces are placed in a pre - heater for 2 - 3 minutes. This brief heating softens the pulp, making it easier to process further. Additionally, it inactivates pectinase, preventing the breakdown of pectin substances and maintaining the desired viscosity of the sauce.

-

Fine Beating: A dual - channel beater, equipped with screens of varying apertures, is utilized to transform the crushed tomatoes into a fine pulp. This process not only achieves a smooth consistency but also separates the peels and seeds, resulting in a more refined product while preserving its nutritional value.

-

Vacuum Concentration: The pulp is transferred to a vacuum evaporation concentration device, such as a double - effect vacuum concentrator. Under a vacuum environment, the pulp is heated, and excess water is evaporated using high - temperature evaporation techniques. Typically, the tomato pulp needs to be concentrated five to six times to reach the desired consistency for ketchup.

The concentrated tomato puree is then moved to the seasoning area, where the flavor profile of the ketchup is crafted. Production staff add ingredients like sugar, salt, vinegar, and spices according to carefully formulated recipes. This step is crucial in creating the unique taste that defines different ketchup brands.

-

Precise Ingredient Weighing: In strict accordance with the product's specific formula, each seasoning, including sugar, salt, vinegar, and various spice blends, is accurately measured. This precision is essential for maintaining flavor consistency across batches.

-

Thorough Mixing: The measured seasonings are added to the concentrated ketchup and mixed thoroughly in a large - scale mixing tank. This ensures that the flavors are evenly distributed throughout the ketchup, creating a harmonious taste experience.

To ensure food safety and extend the shelf life of the ketchup, a sterilization process is carried out. High - temperature sterilization methods are commonly used to eliminate bacteria and other microorganisms.

-

High - Temperature Sterilization: The ketchup liquid passes through sterilization equipment. Common methods include high - temperature instantaneous sterilization or heating the ketchup at 90℃ - 100℃ for several minutes. These methods are designed to minimize the impact on the ketchup's nutritional content and flavor while effectively sterilizing the product.

-

Rapid Cooling: After sterilization, the ketchup is quickly cooled using specialized cooling equipment. This rapid cooling helps prevent flavor degradation and maintains the quality of the product.

The sterilized and cooled ketchup is now ready for packaging. A variety of packaging materials, such as plastic bottles, glass bottles, or flexible packaging bags, are used to preserve the freshness and hygiene of the ketchup. The packaging process involves several types of automated equipment.

-

Bag Packaging: Automatic packaging machines are used to fill ketchup into bags. Options include large bag aseptic filling machines, small bag vertical packaging machines, and bag - feeding packaging machines for self - supporting bags.

-

Bottle and Can Filling: Automatic filling equipment is used to dispense the ketchup into bottles or cans, such as glass bottles, iron cans, or plastic bottles. The filling equipment ensures accurate and consistent filling amounts in each container.

-

Sealing: Sealing equipment is used to seal the filled bottles or cans, preventing air from entering and maintaining the product's freshness.

-

Labeling: Product labels are attached to each container, providing complete product information, including the production date. The labeled products are then packaged and prepared for distribution.

The final stage of ketchup production involves a comprehensive quality inspection of the finished products. This inspection ensures that the ketchup meets all food safety and quality standards.

-

Quality Assurance: Each batch of ketchup undergoes sensory evaluation and laboratory testing to assess its taste, color, texture, and packaging integrity. Only products that meet the established standards are approved for release.

-

Optimal Storage: Passed products are stored in a cool, dry, and well - ventilated environment, away from direct sunlight and areas with high humidity and temperature. This storage condition helps maintain the quality of the ketchup until it is ready for sale and distribution.

In conclusion, every step in the ketchup production line, from raw material selection to the final inspection, is integral to the creation of a high - quality product. The advanced production line equipment provided by Zhengzhou Hongle Machinery Equipment Co., Ltd. not only enhances production efficiency but also ensures the consistent quality and safety of the ketchup. Through these meticulous processes, the resulting ketchup meets the exacting standards of consumers worldwide in terms of taste, quality, and hygiene.

Hot News

Hot News