Automatic 2t/h Cherry Processing Production Line with Branch Stem Removing Sorting Grading Cleaning Function

- Overview

- Recommended Products

- High - efficiency Integrated Operation: The line combines branch and stem removing, sorting, grading, and cleaning functions into one continuous process, reducing manual intervention and increasing overall productivity by up to 40% compared to traditional methods.

- Precision Sorting and Grading: Equipped with advanced optical sorting and grading systems, it can accurately classify cherries based on size, color, and quality, ensuring consistent product quality and meeting different market demands.

- Powerful Cleaning Function: The multi - stage cleaning system uses a combination of bubble washing and high - pressure spraying to thoroughly remove dirt, pesticides, and other contaminants from cherry surfaces, guaranteeing clean and safe products.

- Customizable and Scalable: The production line can be customized according to specific processing requirements, such as adjusting the sorting and grading criteria or adding additional processing modules. It can also be scaled up or down to meet different production capacities.

- Easy Maintenance and Operation: With a user - friendly control interface and modular design, the line is easy to operate and maintain. Regular maintenance can be quickly carried out, minimizing downtime and reducing long - term operating costs.

- Fresh Cherry Producers: Ideal for large - scale fresh cherry growers who need to process harvested cherries quickly and efficiently before transporting them to markets. The line ensures that only high - quality cherries reach consumers, enhancing brand reputation.

- Fruit Processing Factories: For factories that further process cherries into products like jams, juices, and dried fruits, this production line provides a reliable pre - processing step, ensuring that the raw materials meet the required quality standards.

- Food and Beverage Companies: Those involved in the production of cherry - based beverages, snacks, and other food products can use this line to source clean, sorted, and graded cherries, streamlining their production processes and improving product quality.

- Agricultural Cooperatives: Agricultural cooperatives can benefit from this production line by jointly processing members' cherry harvests, increasing the overall value of their produce and improving market competitiveness.

Automatic 2t/h Cherry Processing Production Line with Branch Stem Removing Sorting Grading Cleaning Function

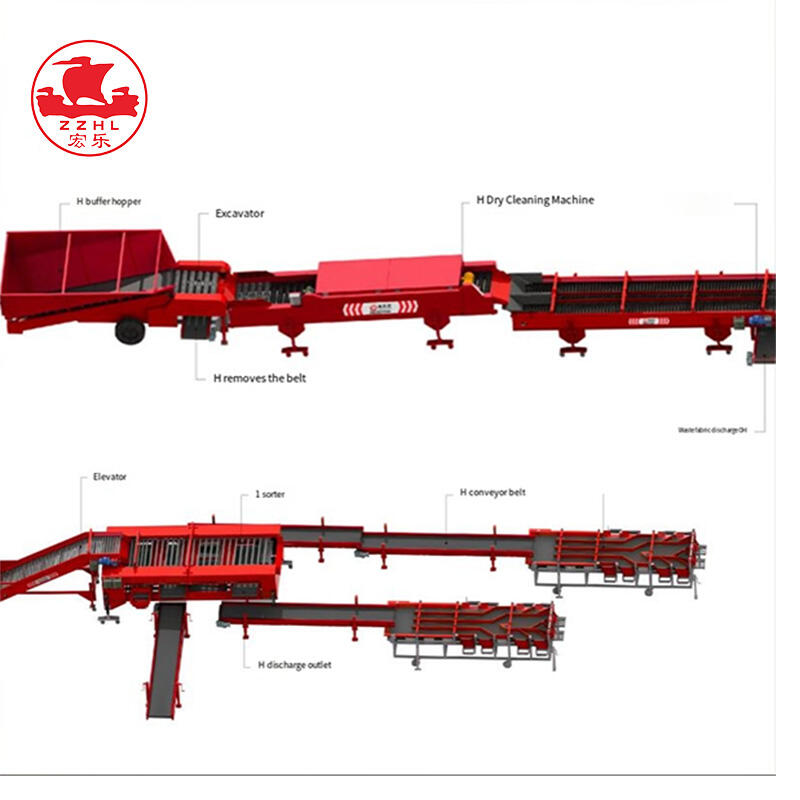

This Cherry Processing Production Line is a comprehensive solution designed for large - scale cherry processing. With an impressive production capacity of 2 tons per hour, it efficiently handles multiple critical processes including branch and stem removal, sorting, grading, and cleaning. The line is constructed with high - quality stainless steel and food - grade materials, ensuring durability and compliance with international food safety standards. It integrates advanced mechanical and intelligent control systems, enabling seamless operation from the moment cherries enter the line until they are ready for the next stage of processing. Whether for fresh cherry distribution or further processing,this production line provides a reliable and efficient processing solution for cherry producers worldwide.

Zhengzhou HongLe machinery & equipment co.ltd is engaged in the development, design, manufacture and sale of meat processing machinery. Zhengzhou HongLe food machinery factory over the years adopts many new ideas, absorbs a wide range of advanced technologies worldwide as well as excellent processing and testing equipment, and takes a reliable strict quality guarantee system and an important aftersales service system to win customers' trust in the industry.

We have strong technical force and standard management. Our existing products are related to the meat processing industry and flour product processing industry, including frozen meat grinders, cutting machines, mixers, saline injection machines, roll kneading machines, filling machines, vacuum and surface machines and mixing trap machines, totally 20 categories of products.

We are willing to join hands with customers for common development and contribute to the revitalization of the food processing industry.

PACKAGE

Standard export carton packing, fit for multiple handing and long distance marine shipping.

DELIVERY TIME

3-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

1) When can I get the price?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

2) How do you make your price?

We make the price according to our comprehensive costing. And our price will lower than the trade company because we are manufacture.You will get competitive price and better quality.

3) Can you guarantee your quality?

Of course. We are the manufacture factory. More important, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

4) How long does the whole procedure being worked out?

After you place a order,the production handling time is about 30-45 days. We need 7 days to prepare all the stuff then 30 days for manufacturing.

5) What about the transportation and delivery date?

Normally we use shipment to transprot the goods.It is about 25-40 days.It also denpends on which coutry and port you are. If there are some emergencies we can send the goods via air express, as long as you afford the traffic expense.