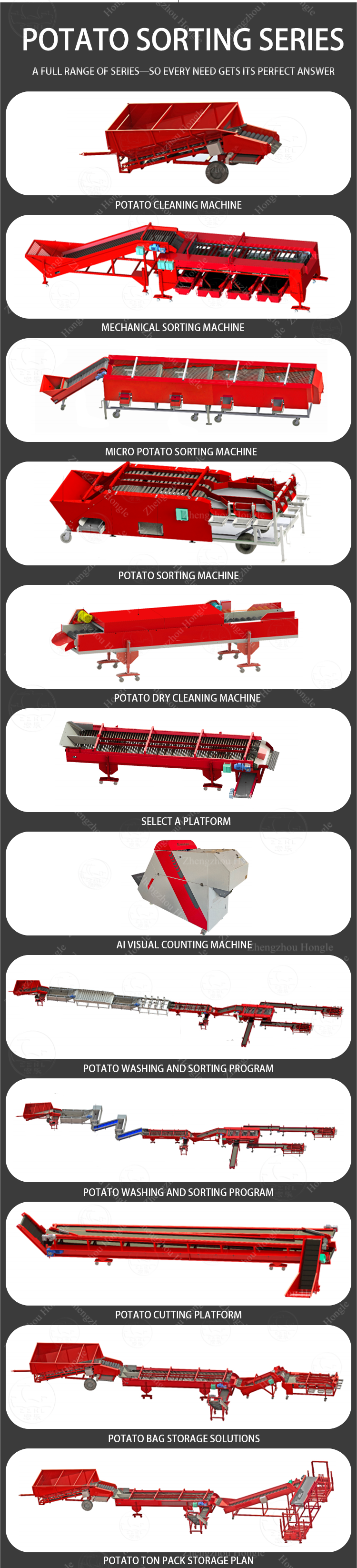

Potato Processing Line with Sorter Machine | Complete Cleaning, Sorting & Packaging for Bulk Potatoes

Commercial Potato Line with Sorter Machine | Customizable Stages: Cleaning, Grading & Packaging

- Overview

- Line Stages & Functions

- Product Advantages

- Application Scenarios

- Technical Parameters

- Detailed Information

- Recommended Products

Potato Processing Line with Sorter Machine | Complete Cleaning, Sorting & Packaging for Bulk Potatoes

Product Overview

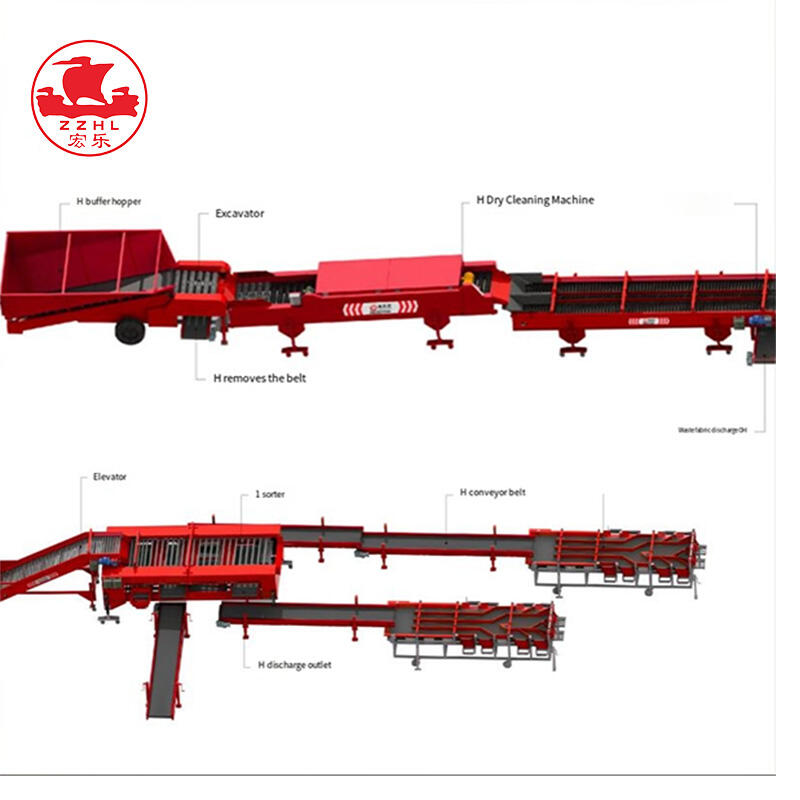

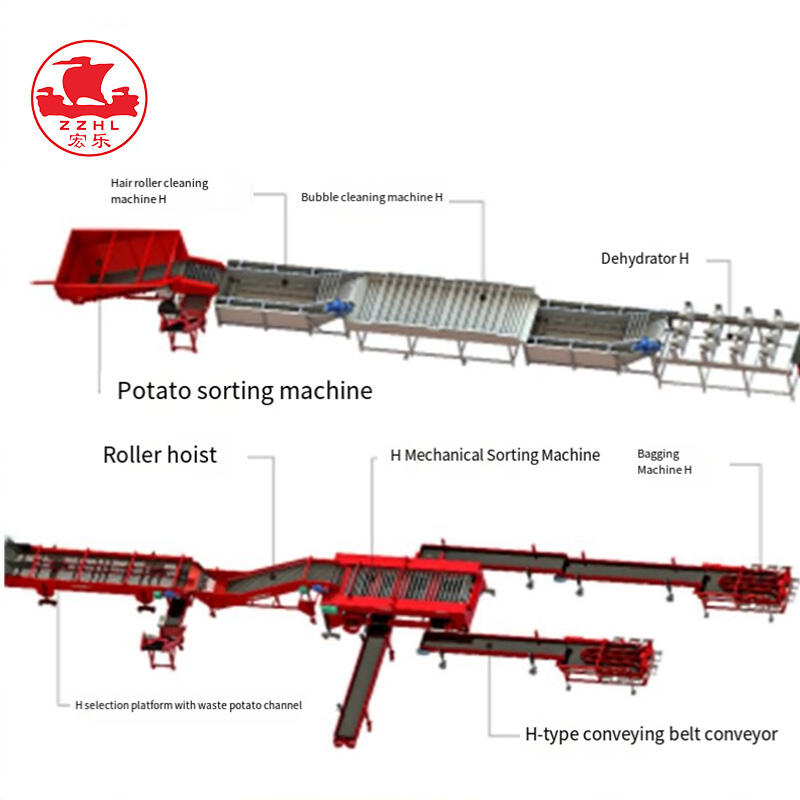

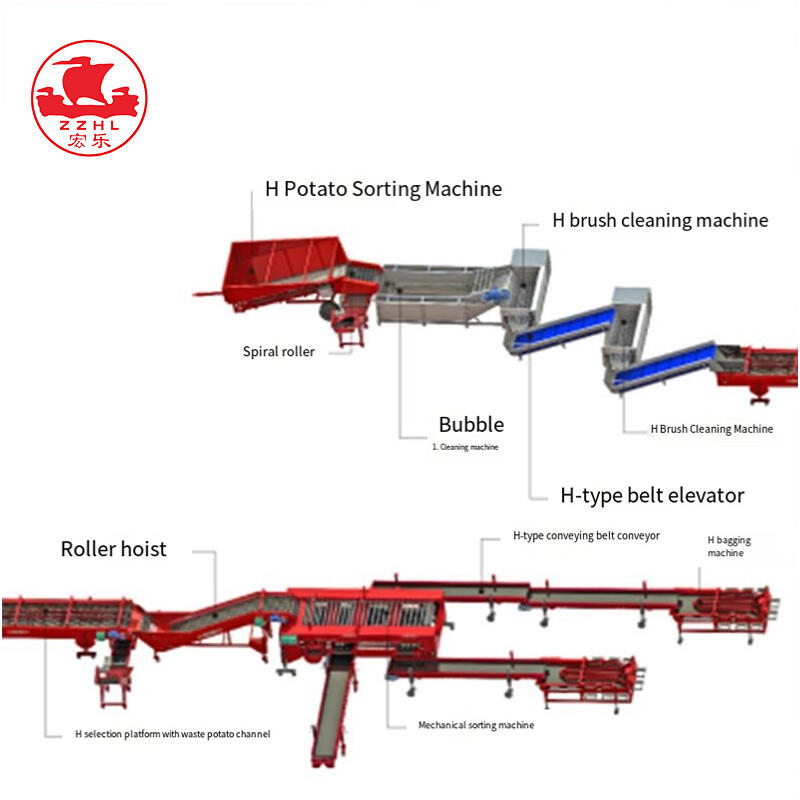

Line Stages & Functions

- Buffer Hopper: Accepts bulk or ton-bag potatoes, ensuring a steady flow to keep the line running without interruptions.

- Soil Removal & Cleaning Roller: Filters out soil and debris, transferring them via a one-way belt for centralized disposal.

- Dry Washer: Uses double-layer brushes to remove surface dirt while protecting potato skins; a bottom belt collects and removes separated soil.

- Sorting Platform (Sorter Machine Component): 360° rotating stainless steel rollers provide full visibility of each potato, allowing workers to remove defects—bad tubers are collected via a dedicated belt for easy disposal.

- Elevator: 360° rotating stainless steel rollers lift potatoes in a single layer, ensuring uniform feeding to the grader for precise sorting.

- Grader (Sorter Machine Core): Double-sided gradual spiral-driven stainless steel tubes with increasing gaps separate potatoes by size, directing them to different belts for grading.

- Conveyor Belt: Transfers potatoes between stages, maintaining a smooth, continuous flow through the line.

- Bagging Machine: Uses partitions to guide potatoes into multiple packaging outlets (each independently operable), enabling non-stop packaging to boost throughput.

Product Advantages

- Sorter Machine Integration: The core grading and sorting functions ensure precise defect removal and size separation, enhancing product quality.

- Modular Flexibility: Stages can be reordered or used independently, adapting to fresh harvests, stored potatoes, or specific processing needs.

- High Throughput: Continuous feeding via the buffer hopper and non-stop packaging enable large-scale processing (ideal for bulk operations).

- Gentle Handling: From brush cleaning to spiral grading, the line protects potato skins, maintaining product integrity.

- Hygienic & Durable: Food-grade stainless steel construction resists corrosion, meets safety standards, and stands up to heavy use.

- Labor Efficiency: Automated feeding, sorting, and packaging reduce manual work, while the 360° sorting platform simplifies defect removal.

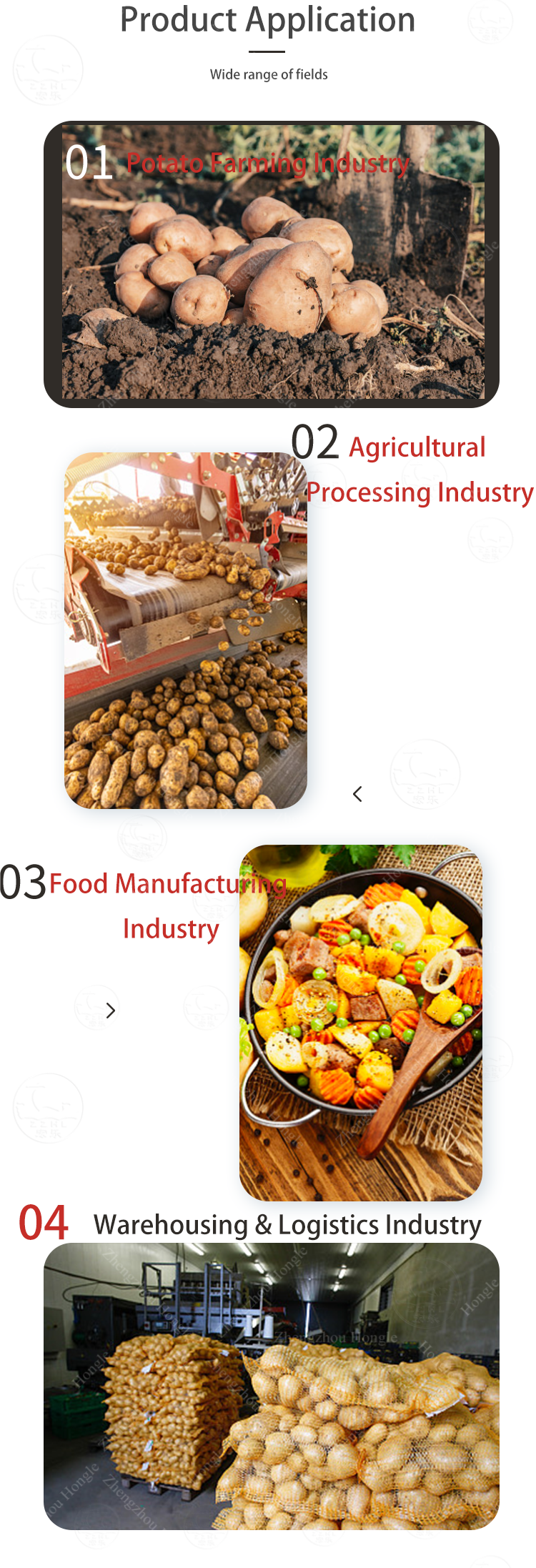

Application Scenarios

- Farm Harvest Processing: Handles bulk or ton-bag potatoes, cleaning, sorting (via Sorter Machine), and packaging for direct sale or storage.

- Storage Facility Pre-Sale Preparation: Processes stored potatoes through cleaning, sorting, and packaging to meet market quality requirements.

- Wholesale & Retail Distribution: Produces uniformly graded, packaged potatoes suitable for bulk wholesale or retail display.

- Food Processing Plants: Prepares consistently sized, clean potatoes as raw materials for chips, fries, or other processed products.

- Agricultural Cooperatives: Centralizes processing of member-grown potatoes, ensuring consistent quality for collective marketing.

Technical Parameters

| Potato dry cleaning machine | Potato sorting machine | |||

| Dimensions | 5300*1550*1350mm | Dimensions | 4350*1700*1200mm | |

| Power | 1.7kW | Power | 0.6kW | |

| Voltage | 220V | Voltage | 220V | |

| Yield | 7-10t/h | Yield | 7-10t/h | |

| Potato selection platform | Mini potato sorting machine | |||

| Dimensions | 5600*2150*1100mm | Dimensions | 7900*1620*1500mm | |

| Power | 0.8kW | Power | 2.6kW | |

| Voltage | 220V | Voltage | 220V | |

| Yield | 5-15t/h | Yield | 300000 per hour | |

| Mechanical sorting machine | AI visual counting machine | |||

| Dimensions | 7760*2700*17000mm | Dimensions | 2900*700*1500mm | |

| Power | 1.7kW | Power | 0.4kW | |

| Voltage | 220V | Voltage | 220V | |

| Yield | 3-5t/h | Yield | 100000 per hour | |

| Bagging Machine | Potato seed cutting platform | |||

| Dimensions | 2700*1650*900mm | Dimensions | 9000*3050*1300mm | |

| Power | 0.2kW | Efficient Width of Discharge Elevator Belt | 550mm | |

| Voltage | 220V | Height of Cutting Table from Ground | Approximately 700mm | |

| Yield | 5-15t/h | Efficient Width of Elevator and Loader Belt | 460mm (Variable Frequency Drive) | |

| Potato Washing Machine | Efficient Width of Discharge Conveyor Belt | 580mm | ||

| Dimensions | 4200*1950*1450mm | Outlet Height from Ground | 800-1050mm (Manual Height Adjustment) | |

| Outlet height | 750-1050mm | Total Power | 1.5kW | |

| Hopper volume | approximately 3m³ | Voltage | 380V | |

| Handling capacity | approximately 15 tons per hour | |||

| Loading conveyor speed | maximum 12m/min | |||

| Power | 1.75kW | |||

| Voltage | 220V | |||

Detailed Information