Commercial Concentration System | Multi-Effect Evaporator, Liquid Concentrator Equipment

High-Efficiency Concentration Unit | Industrial Vacuum Evaporator for Liquid Processing

- Overview

- Product Advantages

- Application Scenarios

- Technical Parameters

- Detailed Information

- Recommended Products

Commercial Concentration System | Multi-Effect Evaporator, Liquid Concentrator Equipment

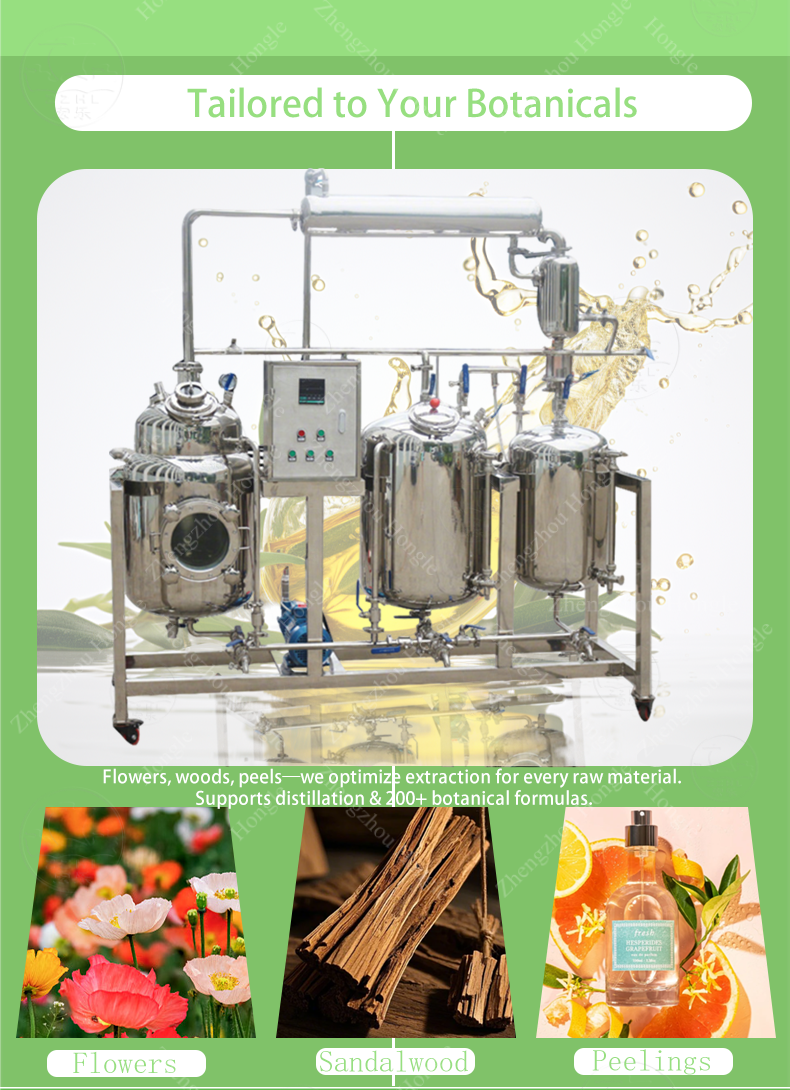

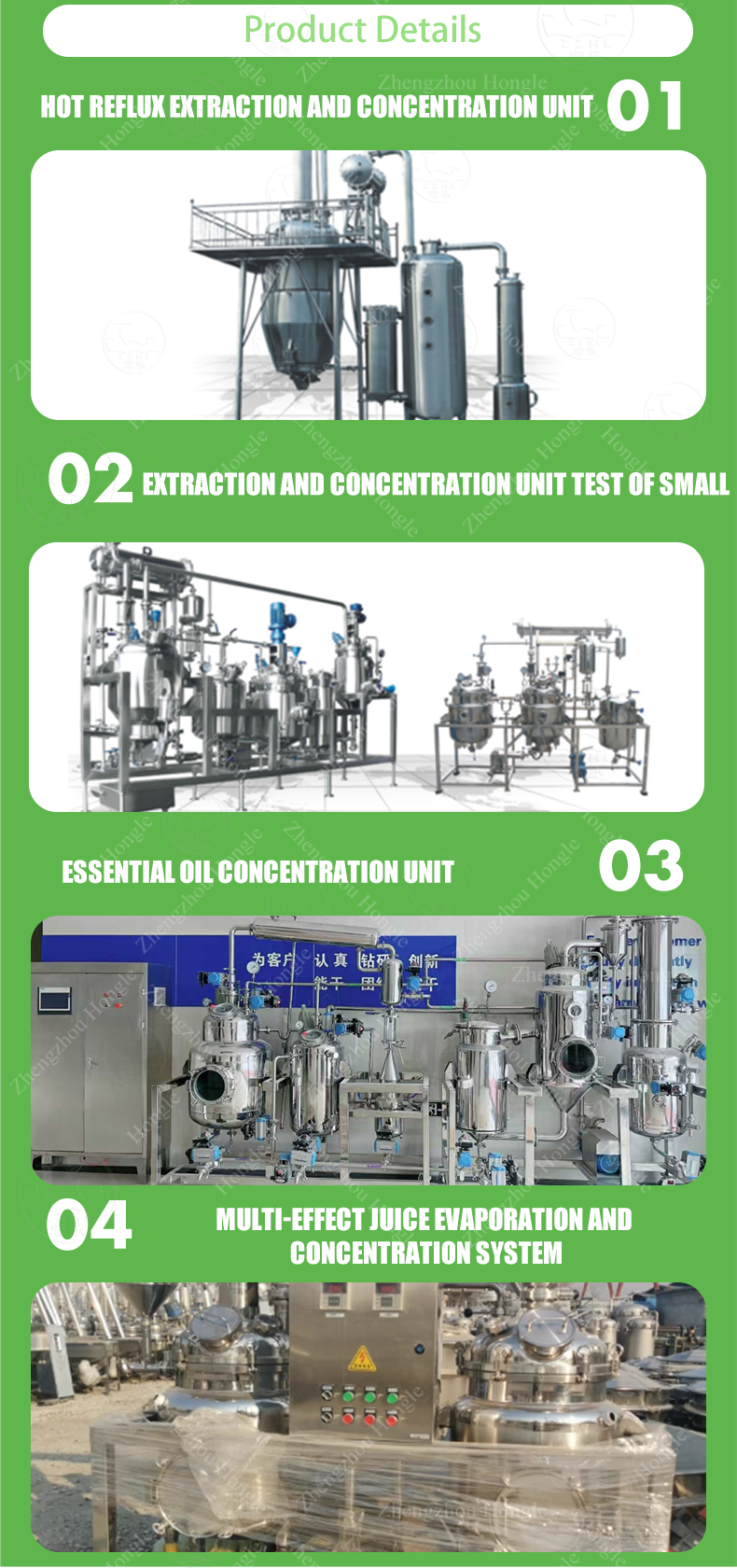

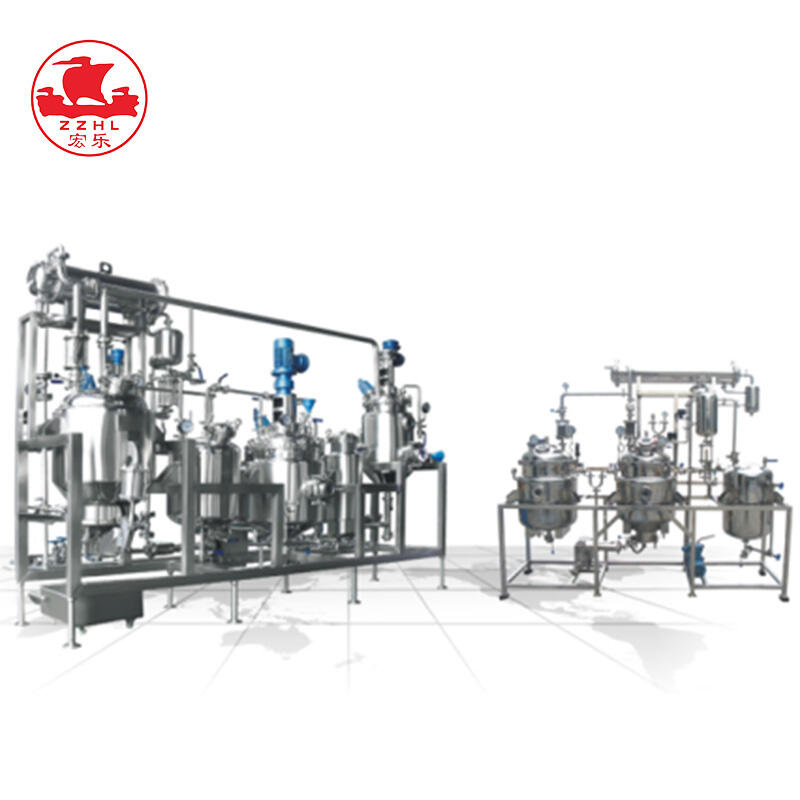

The Concentration Unit is a specialized industrial equipment designed to reduce liquid volume by evaporating moisture, ideal for concentrating solutions like juices, herbal extracts, and food liquids. It typically uses vacuum evaporation technology to lower boiling points (40-80℃), preserving heat-sensitive components while accelerating moisture removal. Constructed with food-grade stainless steel (304/316), the unit features a heating chamber, condenser, and vacuum system, ensuring hygiene and corrosion resistance. With adjustable temperature and vacuum pressure settings, it adapts to various liquid viscosities, making it widely used in food processing, beverage production, and herbal extract industries.

Product Advantages

Efficient Concentration: Vacuum evaporation reduces boiling temperature, speeding up moisture removal while saving energy (30% more efficient than atmospheric evaporation).

Component Preservation: Low-temperature operation protects heat-sensitive ingredients (e.g., vitamins, flavors) in food or herbal liquids.

Hygienic Design: Food-grade stainless steel (304/316) construction prevents contamination; easy-to-clean structure meets FDA/CE standards.

Flexible Operation: Adjustable vacuum pressure and temperature adapt to diverse liquids, from thin juices to thick herbal extracts.

Scalable Capacity: Available in batch or continuous models (50-5000L/h), suitable for small workshops to large factories.

Energy-Saving: Multi-effect designs reuse latent heat, reducing energy consumption by 40-60% compared to single-effect units.

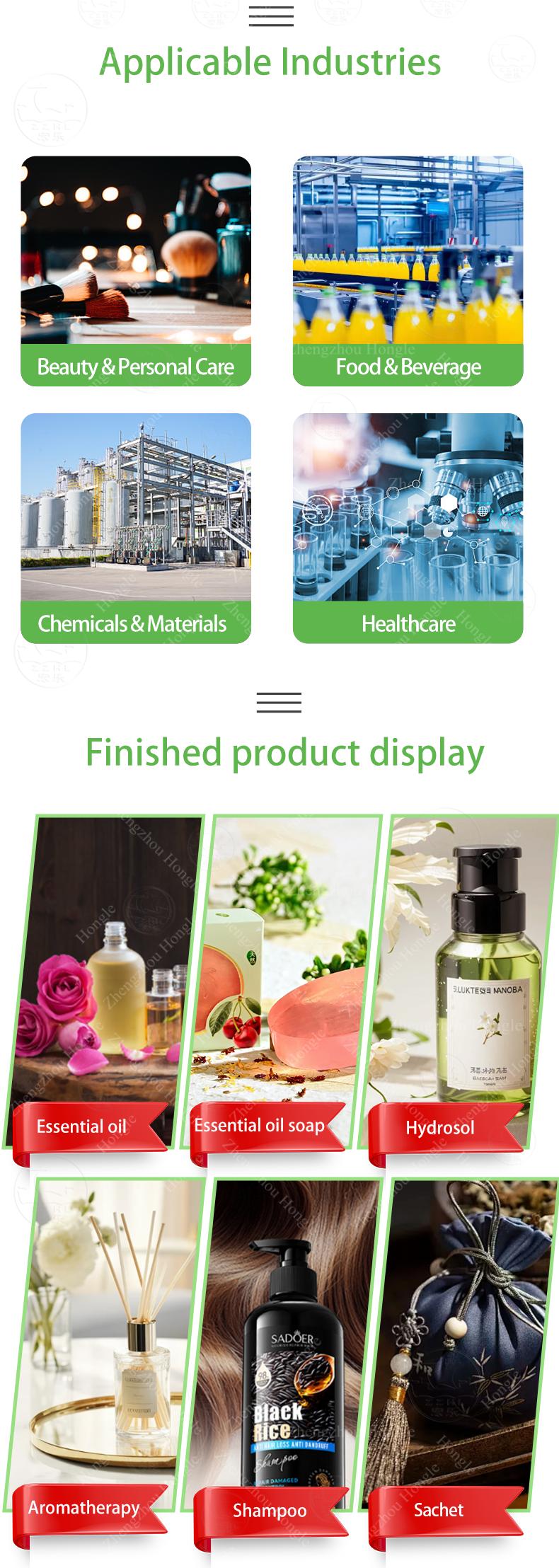

Application Scenarios

Food & Beverage Industry: Concentrating fruit juices, syrups, and dairy liquids to enhance flavor and reduce storage/transport costs.

Herbal & Plant Processing: Concentrating herbal extracts, plant juices, and natural pigments for supplements or cosmetic ingredients.

Condiment Production: Thickening sauces, pastes, and seasonings (e.g., tomato paste, soy sauce) to achieve desired viscosity.

Beverage Manufacturing: Concentrating tea, coffee, and functional drinks to create concentrates for later dilution.

Biotechnology: Concentrating biological solutions and extracts in a controlled, low-temperature environment to preserve activity.

Technical Parameters

| Water evaporation rate | ≥2340kg/h |

| Feed rate | 2500kg/h |

| Feed temperature | 25℃ |

| Feed sugar content | 4 Brix |

| Discharge flow rate | 167kg/h |

| Discharge sugar content | 60Brix |

| Discharge temperature | 30℃ |

| Steam consumption | 1000kg/h |

| Circulating water volume | 30㎡/h(25℃-40℃) |

| Installed capacity | 25KW |

| Evaporation temperature | |

| First Stage temperature | 72~75℃ |

| Second Stage temperature | 59~62℃ |

| Third Stage temperature | 46~49℃ |

Detailed Information