Промышленный электрический гомогенизирующий бак | Нагревание и перемешивание, подходит для пищевой промышленности

Электрический гомогенизирующий смесительный бак | Нержавеющая сталь, легко чистится и эксплуатируется

- Обзор

- Преимущества продукта

- Сценарии применения

- Технические параметры

- Детальная информация

- Рекомендуемые продукты

Преимущества продукта

Сценарии применения

Технические параметры

| Источник питания | Трехфазный 380 В 50 Гц, трехфазный четырехпроводной |

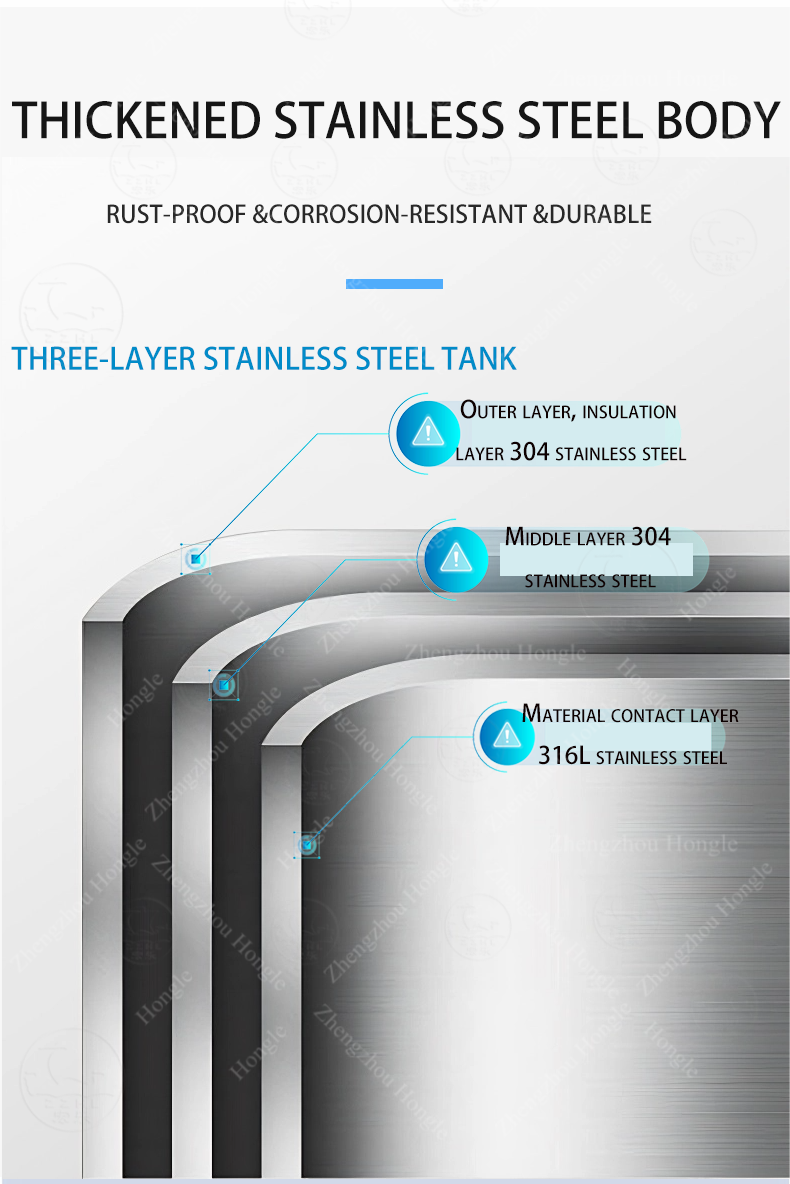

| Судно | Трехслойная, давление внутри межслойного пространства атмосферное, рабочее давление в межслойном пространстве ≤0,1 МПа |

| Толщина листов сосуда | 3 мм внутренний, 3 мм средний, 2,0 мм наружный |

| Материал | внутренний слой из нержавеющей стали 316L, средний и внешний слои из нержавеющей стали 304 |

| Обогрев и охлаждение с использованием рубашки | Рубашка нагревается электрическим водонагревателем мощностью 27 кВт для нагрева и циркуляции воды для охлаждения. Толщина рубашки: 50 мм. |

| Внешний слой | слой соломенной ваты толщиной 70 мм для теплоизоляции и защиты от ожогов |

| Система контроля температуры | Термопара PT100, подключенная к контроллеру температуры, обеспечивает контроль температуры в реальном времени и поддержание постоянной температуры нагрева |

| Система перемешивания | Четырехступенчатый двигатель мощностью 2,2 кВт, вертикальный редуктор с передаточным числом 1-23, рамная мешалка, вертикально установленные скребки из ПТФЭ, частотный преобразователь с регулируемой скоростью от 0 до 62 об/мин, соединение мешалки с редуктором фланцевое |

| Система гомогенизации и эмульгирования | Двигатель двухступенчатый, мощностью 7,5 кВт, гомогенизатор с таймером, 2930 об/мин, механическое уплотнение, гомогенизатор бокового монтажа |

| Крышка: | Открытая плоская крышка, половина которой может открываться |

| Выходной порт | центральное отверстие диаметром 51 мм в днище бака, оснащенное бабочковым клапаном, высота от земли 550 мм |

| Рама поддержки бака | (1140 мм в длину * 1140 мм в ширину * 1000 мм в высоту) квадратная рама для поддержки бака, высота 850 мм от точки опоры до выпускного патрубка |

| Рабочая платформа, лестница и ограждение | Платформа шириной 1000 мм * длиной 1140 мм, с настилом из нержавеющей стали марки 304; лестница шириной 1000 мм с настилом из нержавеющей стали марки 304; ограждение изготовлено из круглых труб диаметром 32 мм |

| Электрический шкаф управления | Кнопочный релейный контроль, один высокий шкаф |

| Расположение | Баки размещены на левой и правой платформах, электрический шкаф находится сзади платформы, а лестница спереди, с огражденной лестничной площадкой |

Детальная информация