Commercial Electric Homogenizing Tank | Heating & Stirring, Suitable for Food

Electric Heating Homogenizing Mixing Tank | Stainless Steel, Easy to Clean & Operate

- Overview

- Product Advantages

- Application Scenarios

- Technical Parameters

- Detailed Information

- Recommended Products

Product Advantages

Application Scenarios

Technical Parameters

| Power supply | Three-phase 380V 50Hz, three-phase four-wire |

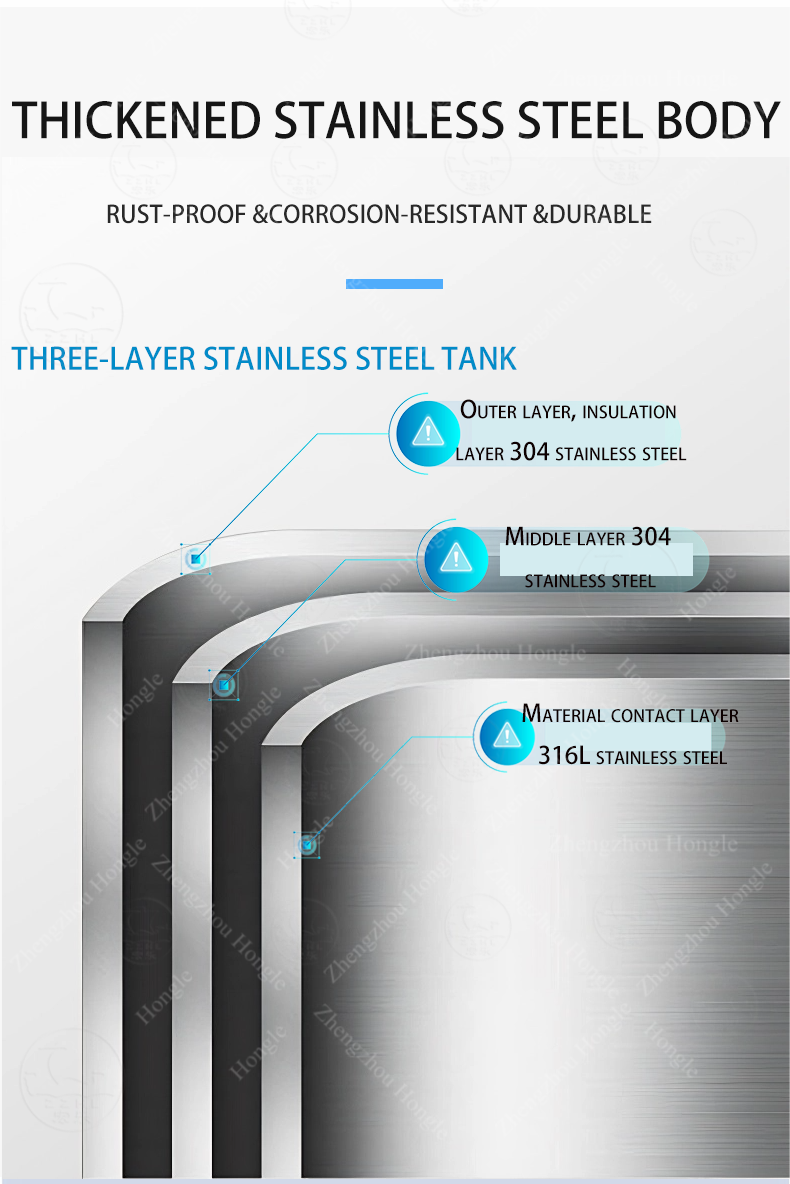

| Vessel | Three-layer, atmospheric pressure inside, interlayer operating pressure ≤0.1MPa |

| Vessel plate thickness | 3mm inner, 3mm middle, 2.0mm outer |

| Material | 316L inner layer, 304 stainless steel middle and outer layers |

| Jacket heating and cooling | Jacket heated by a 27kW electric water heater for heating and circulating water for cooling. Jacket thickness: 50mm. |

| Outer layer | 70mm thick salt wool for insulation and scalding protection |

| Temperature control system | PT100 thermocouple connected to the temperature controller for real-time temperature and heating constant temperature control |

| Stirring system | Four-stage 2.2kW motor, 1-23 ratio vertical gear reducer, frame-type scraper agitator, PTFE scrapers arranged vertically, variable frequency drive with adjustable speed of 0-62 rpm, stirring rod connected to reducer with flange coupling |

| Homogenizing and emulsifying system | Two-stage 7.5KW motor, homogenizer with timer, 2930 rpm, mechanical seal, and side-mounted homogenizer |

| Lid: | Open flat lid, half of which can be opened |

| Discharge port | 51mm center opening at the bottom of the tank, fitted with a butterfly valve, 550mm above the ground |

| Tank support frame | (1140mm long * 1140mm wide * 1000mm high) square frame supporting the tank, 850mm height from support point to discharge port |

| Operating platform, stairs, and fence | Platform is 1000mm wide * 1140mm long, with 304-grade planking; stairs are 1000mm wide with 304-grade planking; fence is constructed of 32mm round pipe. |

| Electrical control cabinet | Pushbutton relay control, one tall cabinet |

| Layout | Tanks are arranged on the left and right platforms, with the electrical box at the rear of the platform and the stairs at the front, with a fenced staircase |

Detailed Information