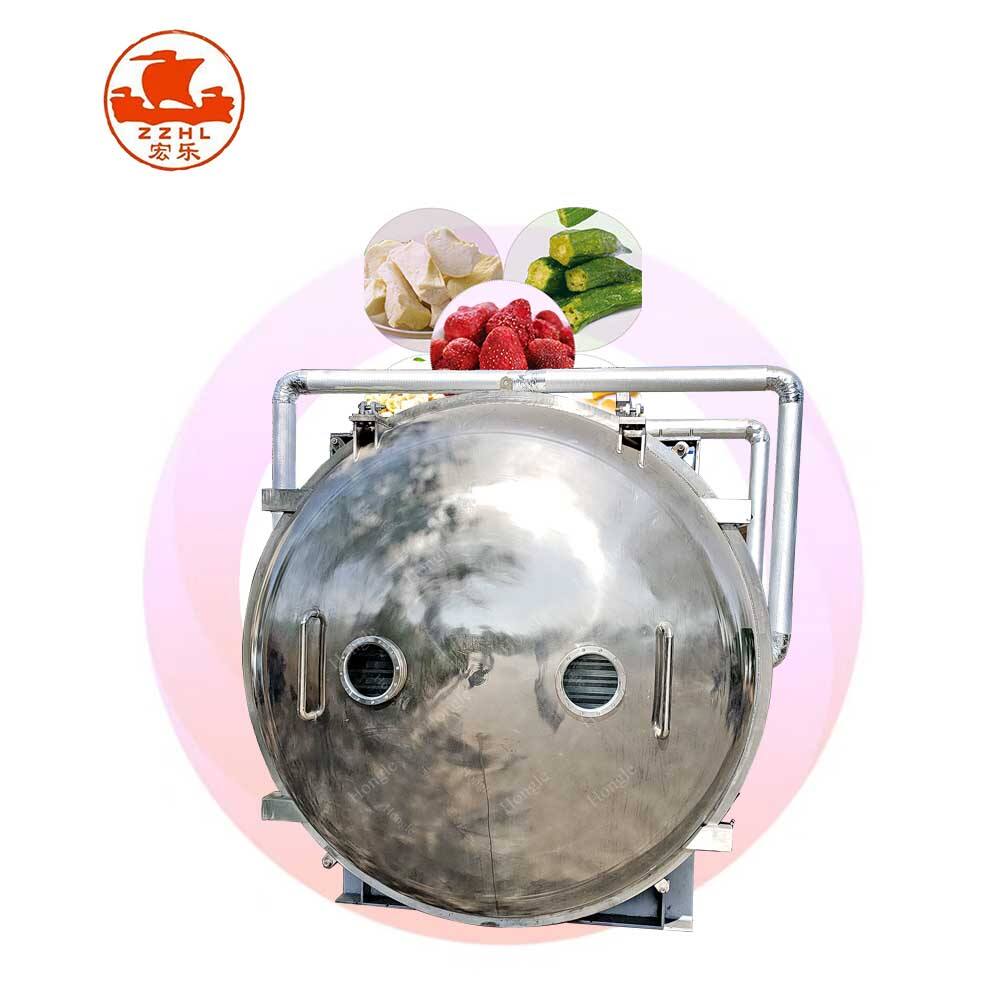

Manufacture vacuum freeze-drying machines The ultimate low-temperature preservation and drying equipment

Fruits vegetables pet food household and commercial freeze-drying equipment Fruit slicing freeze-drying Vegetable dehydration preservation Homemade snacks Vacuum freeze-drying technology retains original flavor and nutritipn

- Overview

- Product Superiority

- Technical Parameters

- Product Application

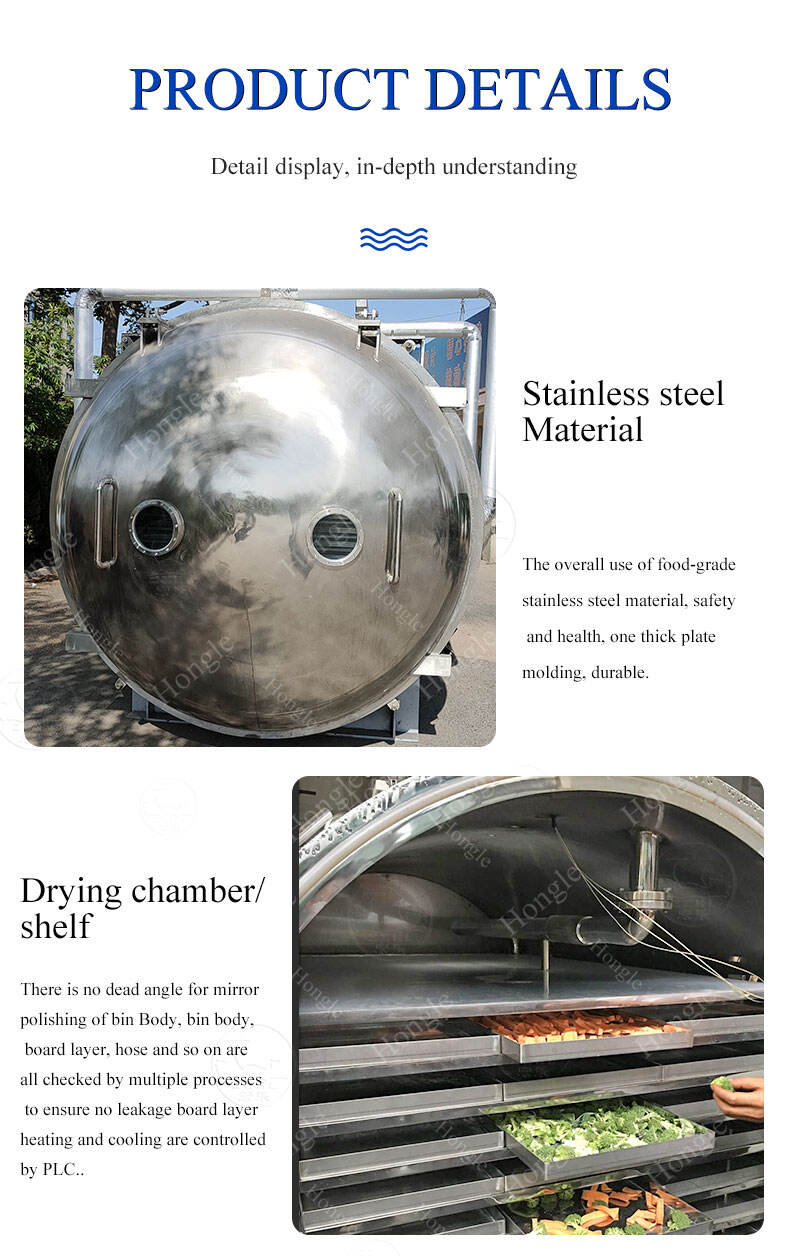

- Detailed Information

- Recommended Products

Manufacture vacuum freeze-drying machines The ultimate low-temperature preservation and drying equipment

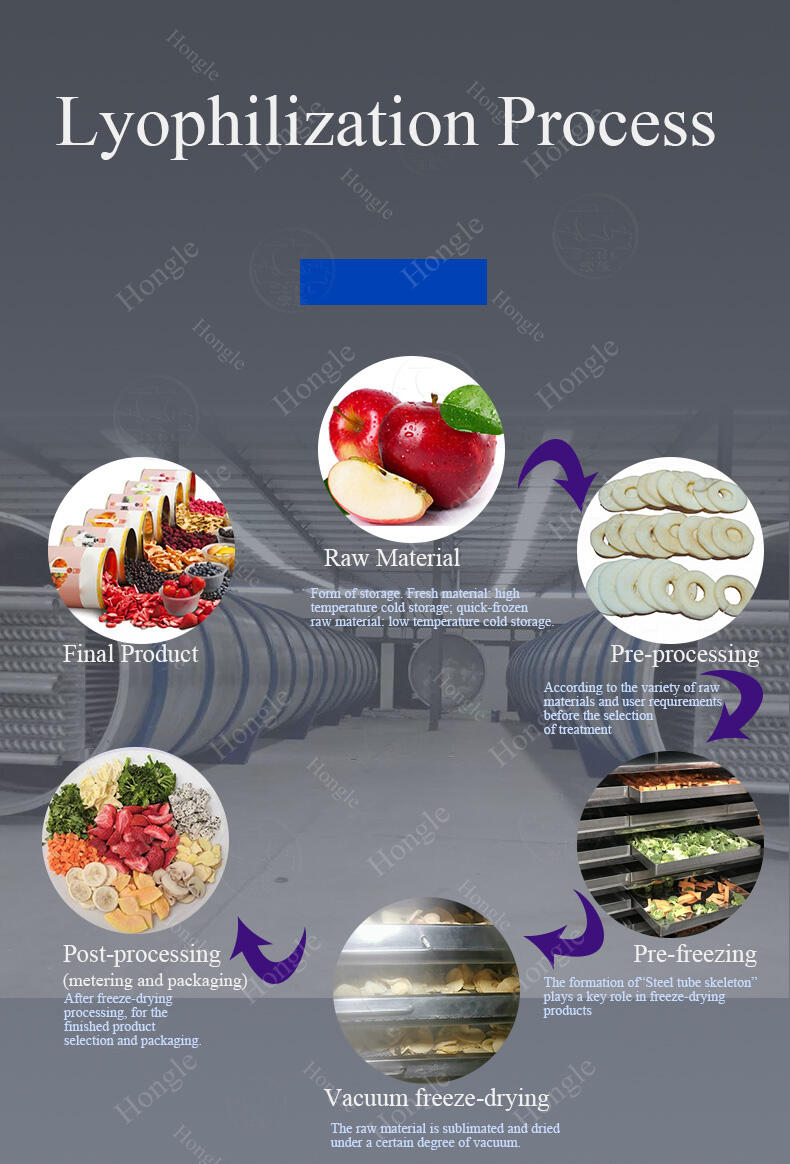

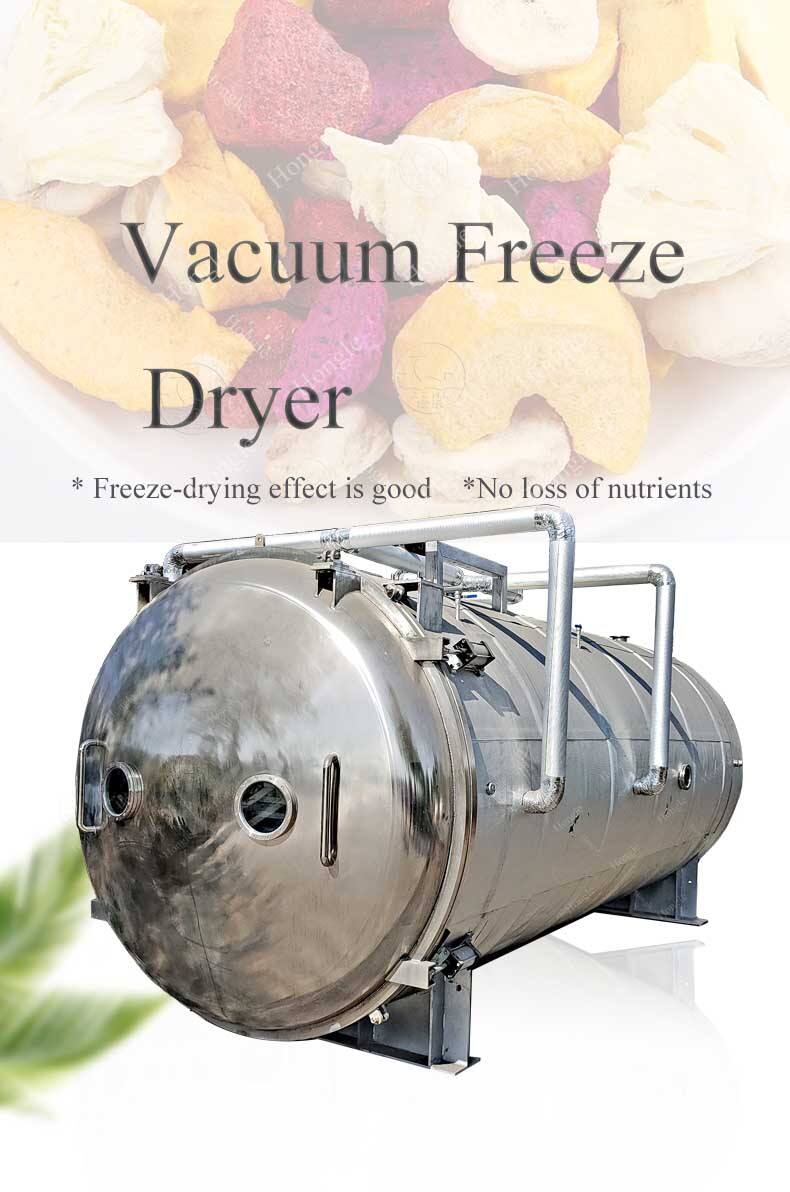

The principle of vacuum freeze-drying is based on the three-phase diagram of water. When the pressure is below the triple point pressure of water (that is, 610.5 pascals), liquid water does not exist. Solid ice can directly sublime into water vapor. During this process, as long as an appropriate amount of heat is provided, the ice will absorb heat and sublime into gas, thereby achieving the dehydration of the material. Therefore, it is also called freeze sublimation drying.

Product Superiority

Technical Parameters

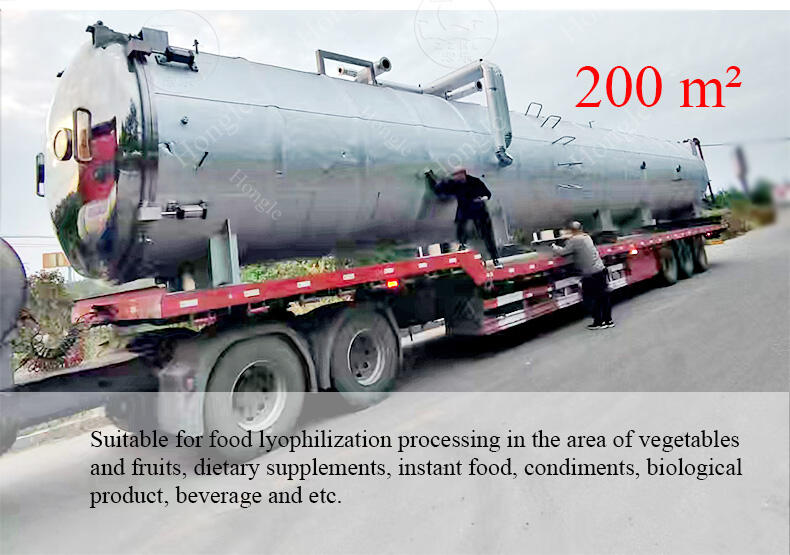

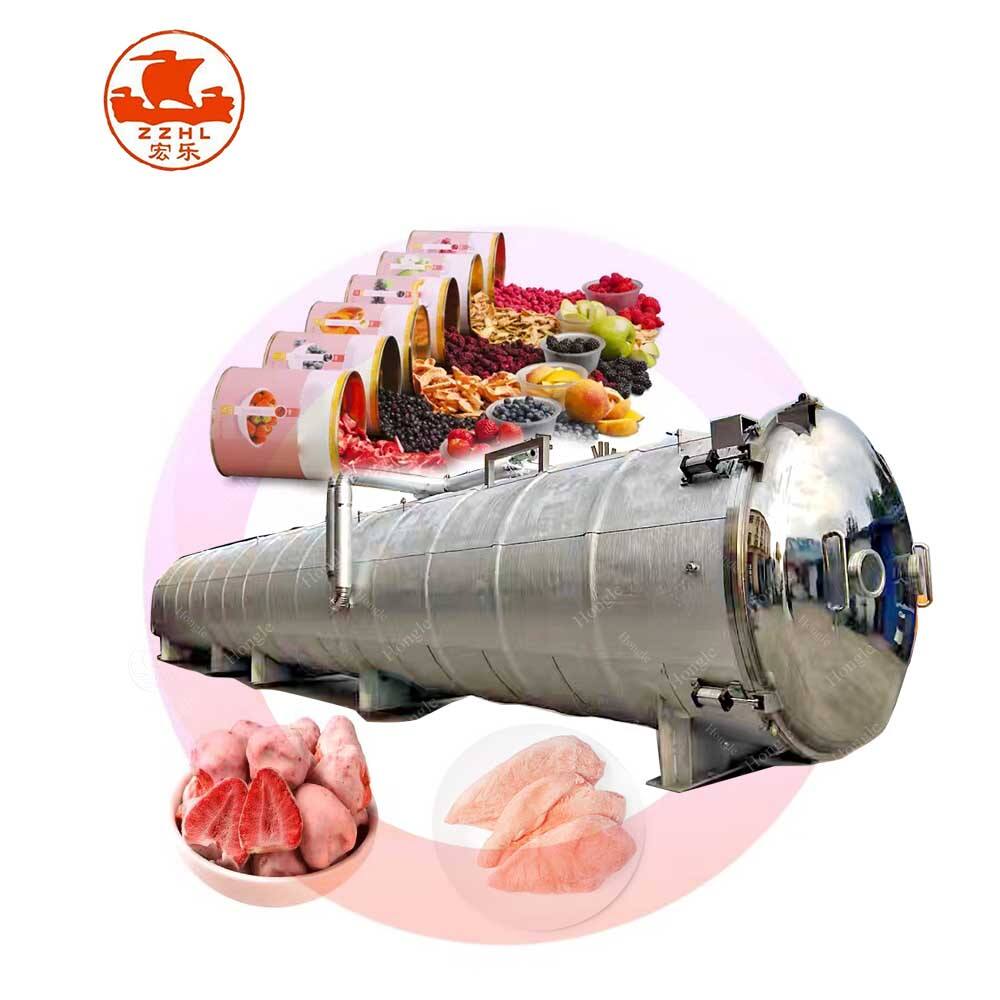

Product Application

Suitable for food lyophilization processing in the area of vegetables and fruits, dietary supplements, instant food, condiments, biological product, beverage and etc.

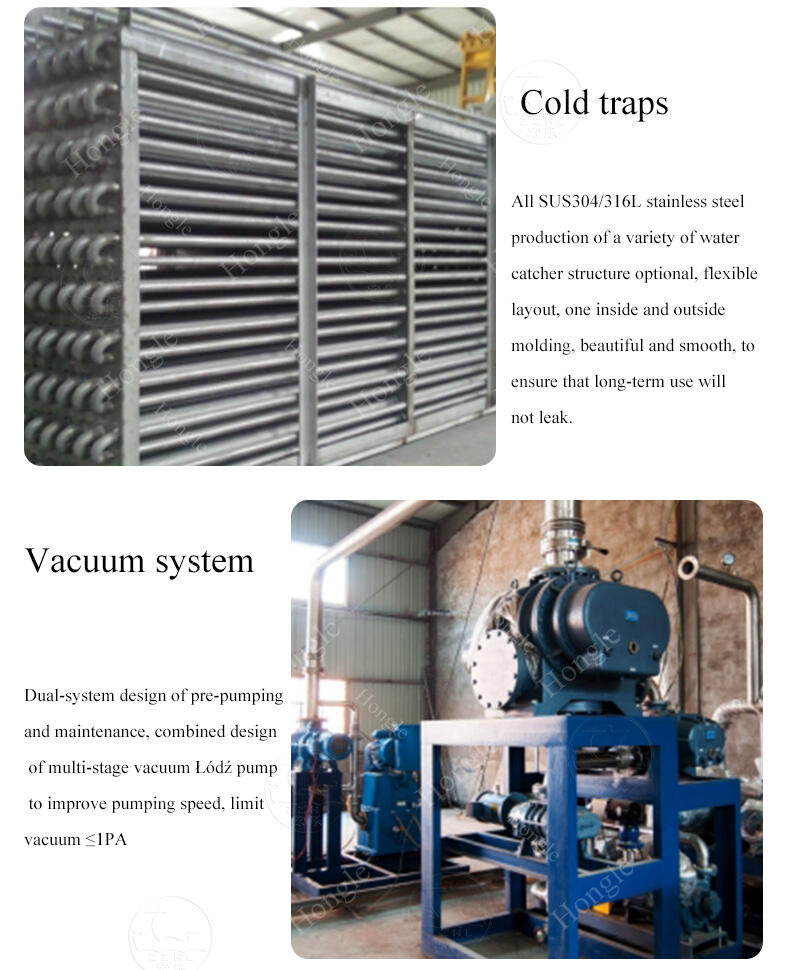

Detailed Information